1. If local codes permit connection of the frame-

grounding conductor to the neutral (white wire),

connect the green and white wire from the supply

cable of the appliance together and to the neutral

(white) wire In the IunctIon box Connect the remaln-

Ing wires from the supply cable. matching the colors.

to the wires in the junction box.

2. If local codes DO NOT permit frame grounding to the

neutral,

separate the white and green wires that

extend out of the end of the supply cable of the

appliance. Connect the white wire from the supply

cable to the neutral wtre In the junction box.

Connect the black and red wire from the supply cable.

matching the colors. to the corresponding wires In the

Junction box The green wire MUST now be used to

ground the appliance In accordance with local

electrl-

cal

codes. Connect the green ground wire to a

grounded cold water plpe*or to the grounded lead In

the service panel.

Do not ground to a gas supply pipe.

Do not connect to electrical power supply until

appliance IS permanently grounded Connect the

ground wire before turning on the power. See Figure

2

COPPER

GROUNOWIRE CAOUNOEOCOLD

WATER PIPE

(REMOVE PAINT ETC,

/I

FIGURE2

*Cold water pipe must have metal contlnulty to e!ectrical

grcund and not be Interrupted by plastic. rubber or other

electrically insulating connectors (Including water meter

or pump) without adding a jumper wire at these connec-

bor1s

CALJTION - If connecting to a four-wire electrIcal syste:n

(MOBILE HOME) the .jppllance frame

MUST NOT

be

connected to the neutral wire of the four-wire electrlcal

sys-em.

Separate the u?tte and green wires that extend

out of the end of the supply cable of the appliance

Corlnect the white. red and black wires from the supply

cable. matching the colors. to the corresponding wires In

the

junction box. Connect the green wire from the supp!y

cable to the ground wire In the IunctIon box

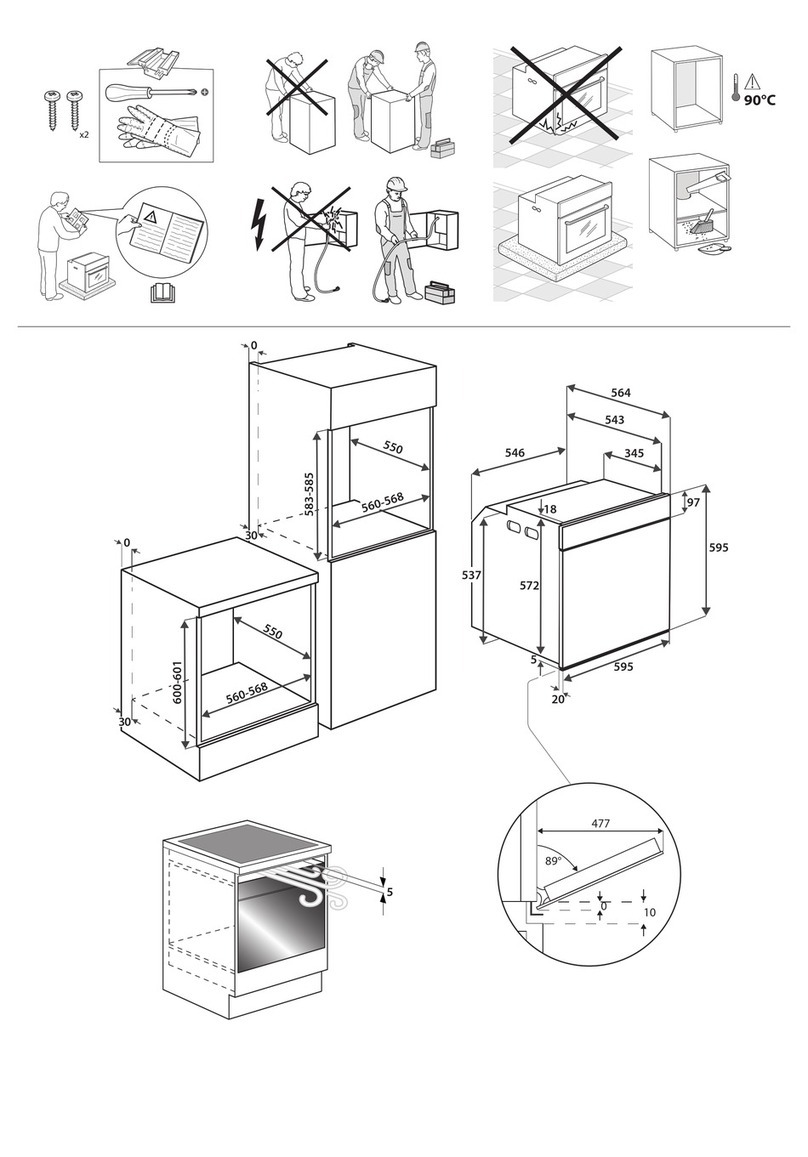

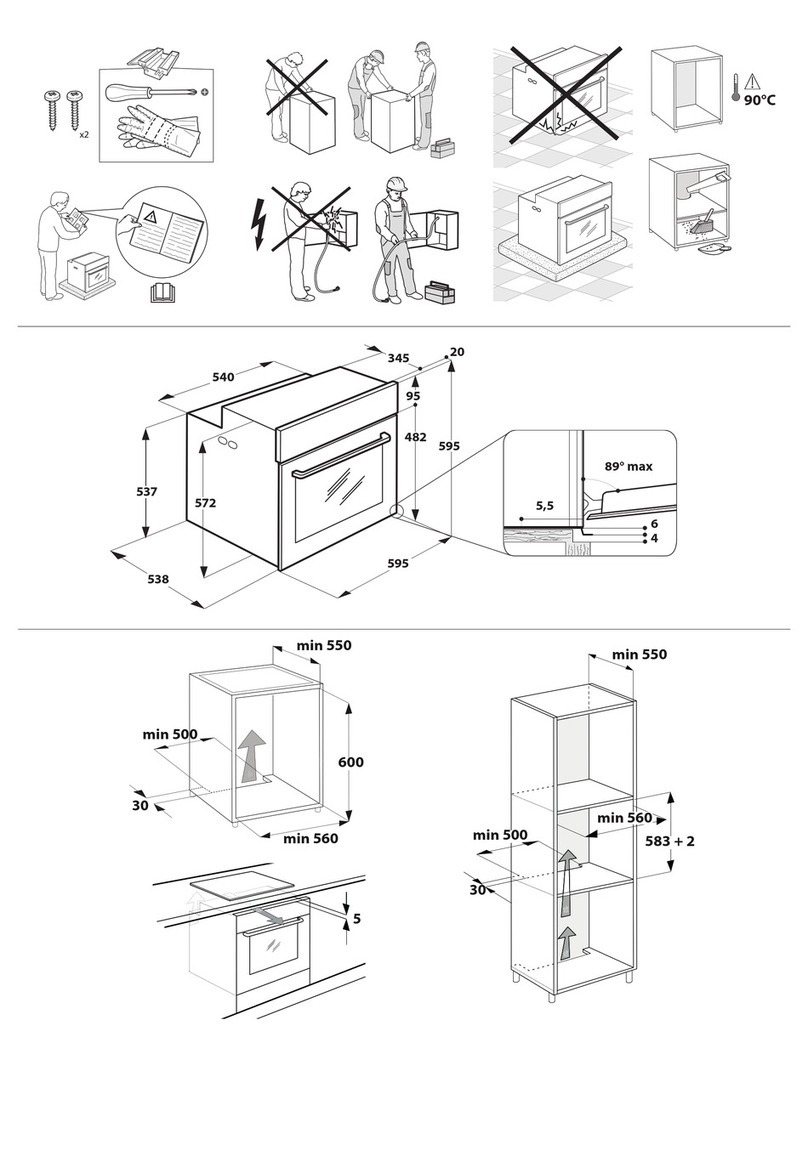

3. INSTALLATION

NOTE.

Bb:‘fc

IP ilisldthny the rang,’ in

the clltoot,

II inay 11~

hc!pfLrl

tc Icmove the

oven floor SW drtails heloiv

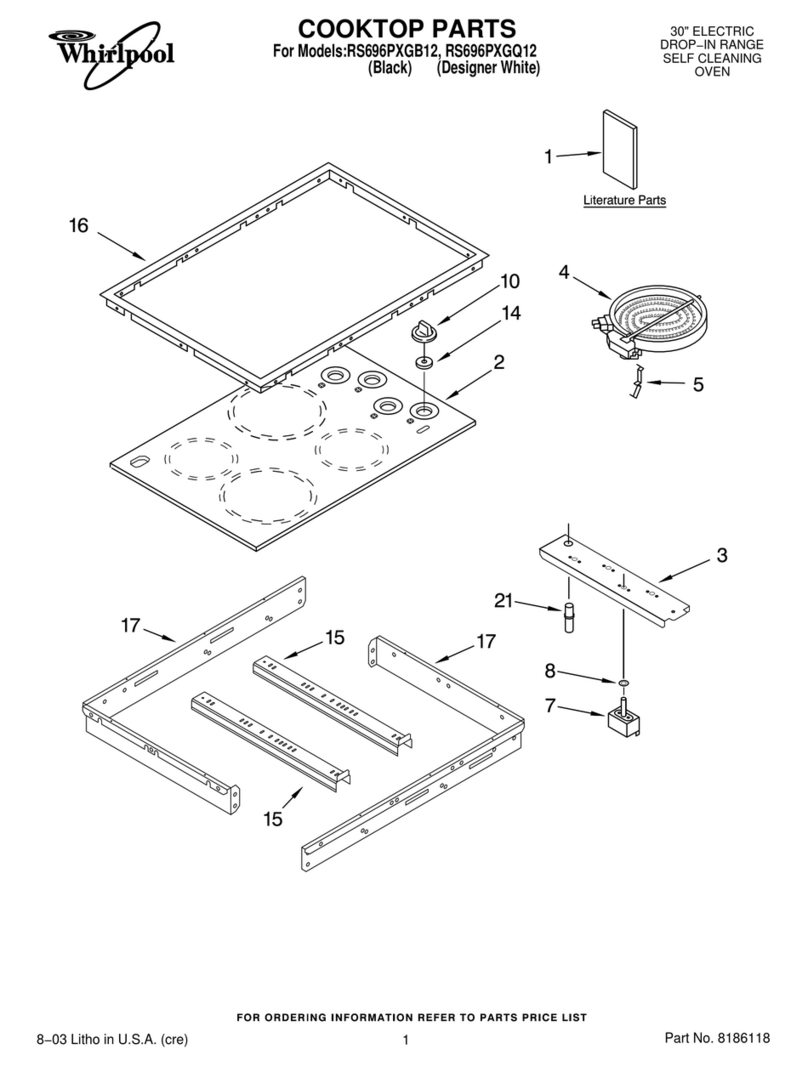

Insert appliance into cut-out. Screws are provided for fasten-

ing the front frame of the appliance to the cabinet. The moun-

ting holes in the front frame of appliance may be used as a

template to locate the appliance mounting screw holes.

CAUTION: For your personal safety, and to minimize poten-

tial personal injury, this oven must be securely fastened

to the cabinet, using the four screws that are provided.

Use caution when mounting oven in cutout so you do not

overtighten screws and cause porcelain chippage or punc-

ture oven cavity.

TO REMOVE OVEN

View

a View b

1. Open door fully

2. Swing the 2 clips located on door in front of hinges so they

cross over the hinge slots (View a).

3. Close the oven door slowly until you feel it stop.

4. Loftup slightly allowing the bottom of the door to swing out.

(View b) Note that the top of the door must be tilted toward

the oven at this point to allow hing arms to swing free. If

appliance IS so located that you cannot grasp both sides

of door you may grasp the door by handle (View c) and

follow same procedure outlined above.

TO REPLACE OVEN DOOR

View c

View d

1. Grasp door by sides (View b) or by handle and align hinge

arms on door with TOP of slot in oven sides.

2. Tilt

top of door toward the oven (View b) and allow door

to “ride” into position. A slight lifting and inward pressure

toward the bottom of the door will make sure it seats pro-

perly. (View d).

3 Open door fully and swing the clips away from the slots

(View a).

3