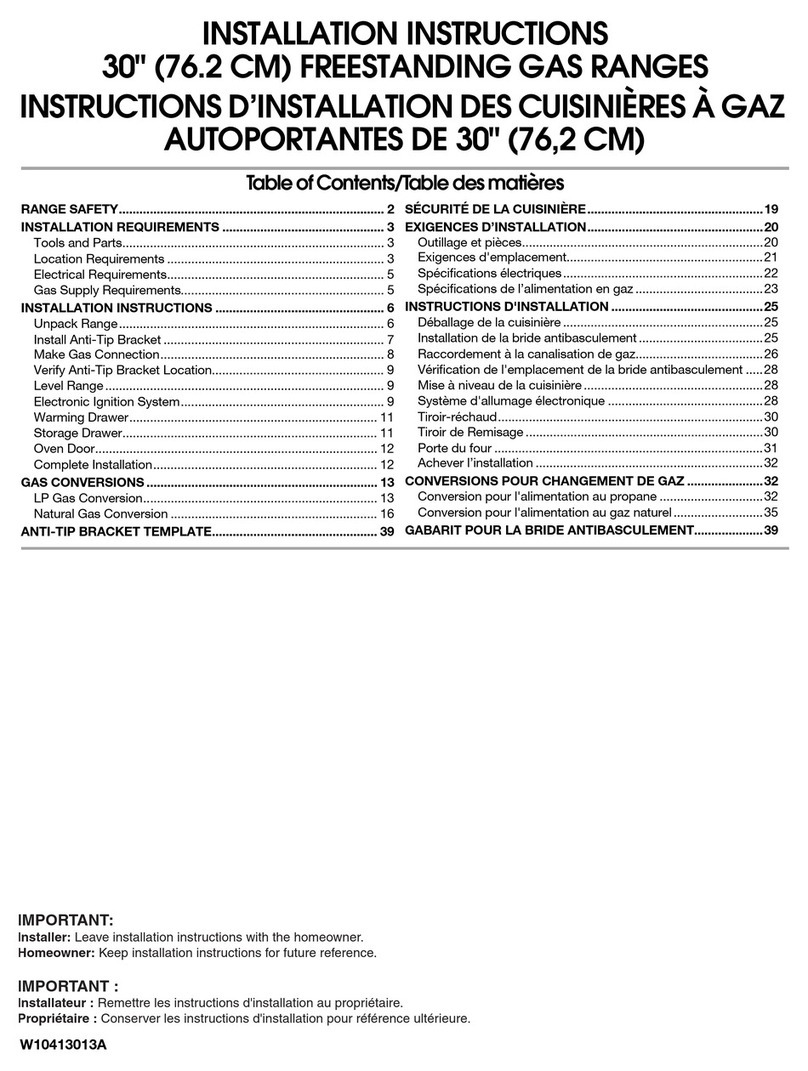

C.

This range is equipped for use

with NATURAL gas II IScetilfled by

A.G.A for NATURAL and L.P gases with

opproprlate convenion.The serial/rating

plate located under the cooktop has

information on the type of gas that co” be

used If this information does not agree with

the type of gas available. check with the

local gas supplier. See bock cover for L.P

gas conversion instructions.

Dm qrovlde a gas supply line of zy

rIgId p,pe to the range locatIon.

A smaller size pipe on long runs may result in

lnsufflaent gas supply Pipe joint compounds

resistant to the action of L.P gos must be used

With L P gas. piplng or tubing size co” be Yz’

minimum. L.P gas suppliers usually determIne

the size and moterlols used on the system

E.

If local codes permit. A G.A.

ODDrOVed flexible metal tubing IS

recommended for connecfing this rangeto

the gas supply Ilne. Do Noi kink or domoge

the flexible tubing when moving the range

A Yz” male pipe thread ISneeded for

connection to pressure regulator female ,

pipe threads.

The supply line should be equipped

with o shutoff valve This valve should

be lccoted I” the some ram as the ro”Qe

and should be I” C location that allows ease

of opening and closing Do Not block access

to shutonvalve

G.

If rlgld pope is used OSo gas supply

Ilne. o comblnat1on of Dice fiHinas

must be used to obtain on in-line cbnnech&

to the range. All strains must be removed from

the supply and fuel lines so range will be

level and in line.

H.

The inlet pressure to the regulator

should be as lollows for both

operation and checking regulator setling.

NATURAL GAS:

Mlnimum pressure 6 Inches

Marlmum pressure14 inches

L.P. GAS:

Mlnlmum pressure 11Inches

Maximum pressure14 inches

I . Line Pressure 1esthlg

Testing aboveK lb. PSI (Gauge)

The range and its individual shutoff valve

must be disconnected from the gos supply

piping System during any pressure testing

of that system ot test pressures greater than

Yzpsig (3.5 ItPa].

Testing at Yzlb. PSI (Gauge) or lower

The range must be isolated from the gas

supply plplng system by closing its Individual

manual shut&valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than Yzpsrg

(3.5 kPo).

Electrical

requirements

A 120 Volt. 60 Hz. AC only. 20 Ammere. fused

electncol supply is required A time-delay

fuse or circuit breaker ISrecommended

It ISrecommended that o separate circuit

serving only this appliance be provided

WARNING: AN EXTENSION CORD SHOULD

NO1 BE USED WITH THIS APPLIANCE. SUCH

USE MAY RESULT IN A FIRE, ELECTRICAL

SHOCK, OROTHER PERSONAL INJURY

Wlrlng diagrams ore Included on the back

cover of these instructlons. A kxhnkx! sheet

that includes the winng dlograms con be

found behlnd the control panel.

Recommended

grounding method

60 NOT, UNDER ANY CIRCUMSTANCES,

REMOVE IHE POWER SUPPLY CORD

GROUNDING PRONG.

Foryourpersonol safety. ihls appllonce must

be grounded This appliance is equipped

with o power supply cord having 0 3-prong

grounding plug. To minimize paslble shock

hazard. the cord must be plugged into o

mating J-prong grounding type wall

receptacle. grounded in accordance wtth

me Natlonol Electrical Code. ANSIINFPA

70.1987” and local codes and ordinances

see Figure 1. If 0 mot1ng “all receptacle IS

not available, It ISthe

c%rsonal resrwnsibilitv

&nd obllgot/on of the’

Temporary -

grounding method

DO NOT, UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

lJ Figure 2

Electrical ground is required on this

If ChonglnQ and properly Qroundlng the “all

receplocle ISlmposslble and where loco1

codes Dermlt fconsult vour electrlcol

inspecior]. o tempo& adopter may be

plugged Into the existing Z-prong wall

receptacle to mate wllh the J-prong power

SUDpfY cord.

If this 1sdone. you must connect o separate

copper grounding wire (No 18 mInimUm)

to 0 Qrounded cold water pipe’ by

means of o clamp ond then to the

edernal grounding Connector screw.

Figure 5

Recommended duct length

Use 3%” x to’ or 6” duct with o maximum

length Of 26 feet for duct System. For best

cerformance use no more than three 90

elbows To colculote fhe length of system You

need. odd the equivalent feet for each duct

piece used in the system. See the following

example.

W’Xlo” duct system

t Maximum length = 26 feet

3”. l-9velbow = 5ft

+ 1- WQII COP = OH

9 feet straght = 9ft

Length of

3’Yd”x lo’system = 14 ft

Recommended standard fitting!

Do Not ground to a gas supply pipe or hot

water pipe. Do Not connect lo electnc

supply until appliance is permanently

grounded See Figure 2.

‘Grounded cold water pipe must have

metal continuity to eleCtriCol ground

and not be interrupted by plostlc.

rubberorotherelectricolfy insulahng

connedon such os hoses, flnlngs,

washers or gaskets [InClUdIng waler

meter or pump]. Any eleclrlcal

insulating connecfor should be

lumped as shown with o length of No. 4

wire securely clomped to bare metal

at both ends

6” duct system

Ventfng

requsrements - +J

2II

3

Moxlmum lenglh=26feet

1 -transition = 45ft

Ductwork needed for installallon is not 2 - 90” elbows = loft

included. Wall or roofcaps used must

have back-draff damper. IO6%%m 1 -;r;;;&,,, 1 ; ZJ

DetermIne which oulslde ventlna method Length of 6” system = 22.5 ff

needs to be used. Note. If o non~enting

(rearculat~ng] installotlon ISdesired. you will

need to order Non-vent Kit 814023 and follow

install&on instructions provided withthe kit

The length of ductwork ond number of

elbows should be kept too rn~“~m”m to

provide eftlcrent performance The xe of the

ductwork should be uniform. Do Nof install

two elbows tooether. Use duct taoe to seal 011

]olnts I” duct $tem. Ductwork cb” terminate

either through the rwf or wall, Figures 3-5

show comnion venting methods-and what

types of materloIs ore needed. Use coulklng

to seal exterior wall or rc0f opening around

exhaust hc&

Recommended standard fittinas

PANEL B