White LGT-165 User manual

Other White Lawn Mower manuals

White

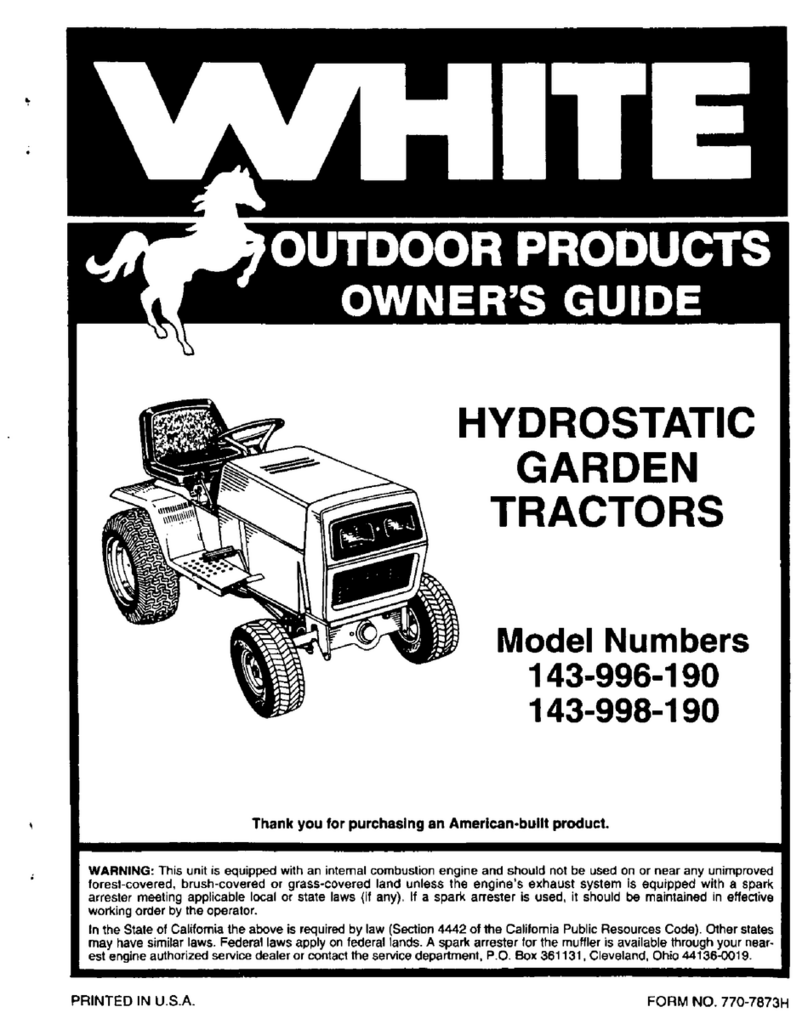

White 143-998-190 User manual

White

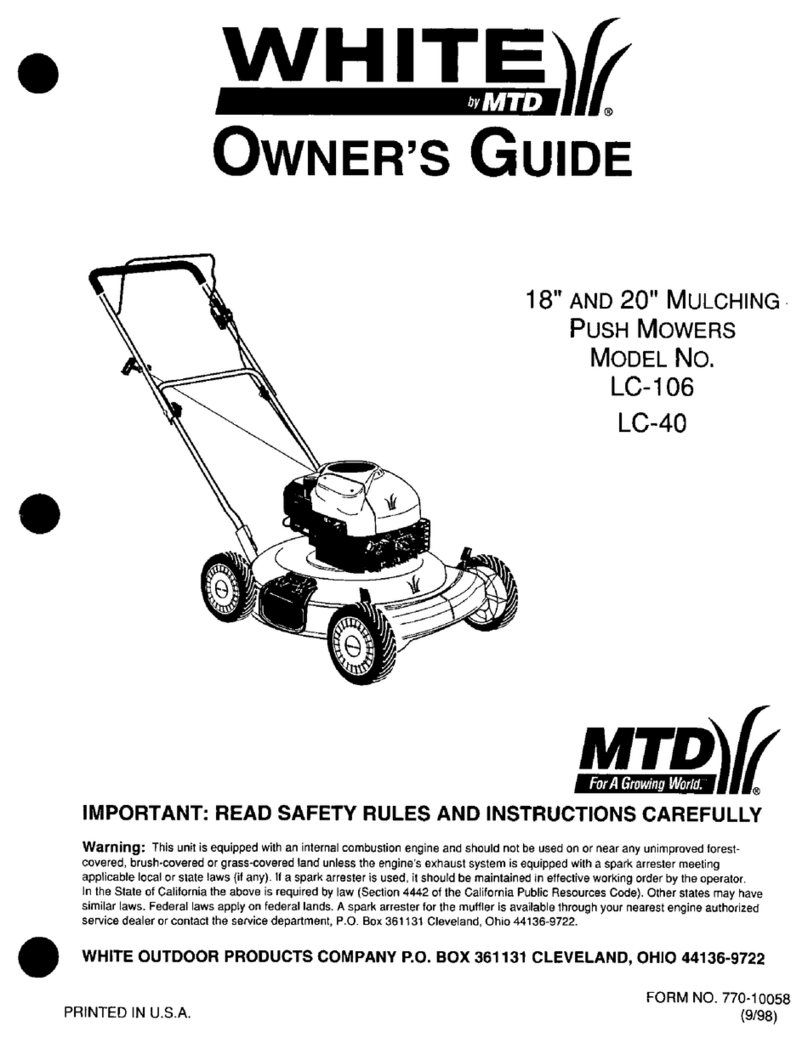

White LC-106 User manual

White

White 833E Series User manual

White

White 960-969 Series User manual

White

White Cell Phone User guide

White

White Z-165 User manual

White

White Lawn Boss 118-434R190 User manual

White

White FR-1800 User manual

White

White LT-185 User manual

White

White LC-436 User manual

White

White 11A-106F190 User manual

White

White CruiseMatic GT-180 User manual

White

White 400 Series User manual

White

White 950-959 Series User manual

White

White LT-135 User manual

White

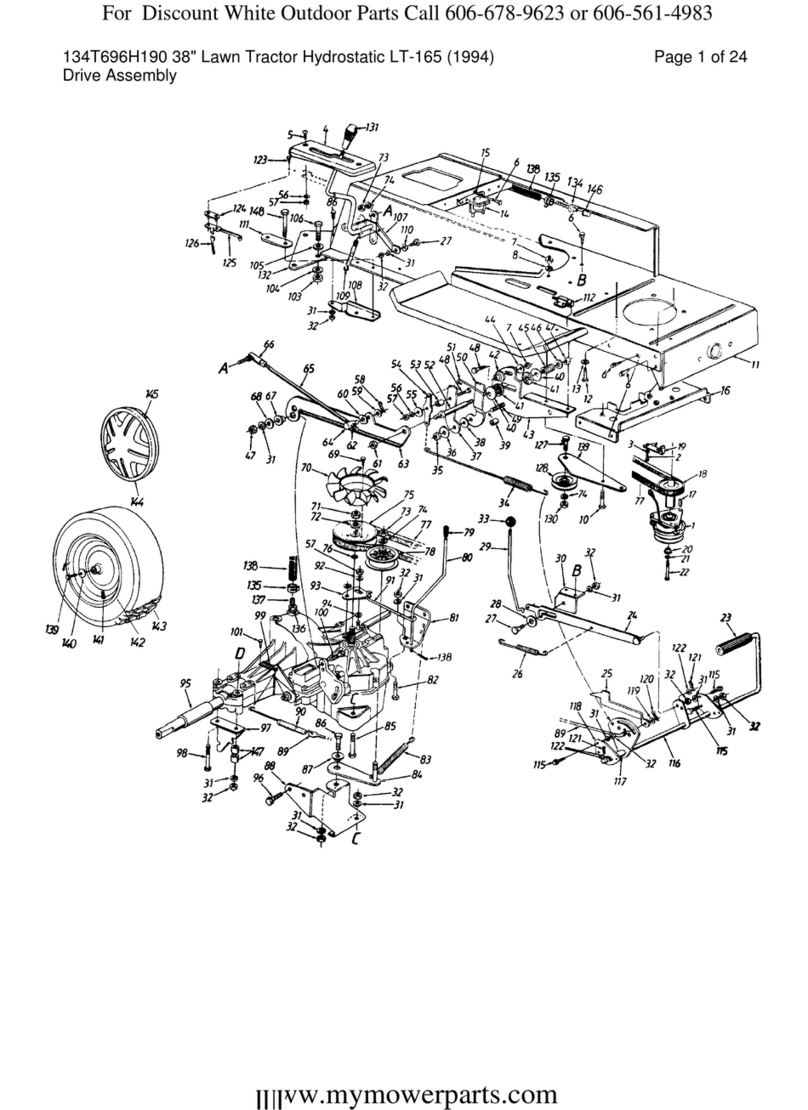

White 696 Series User manual

White

White L-12 User manual

White

White 436 Series User manual

White

White 133H471F590 User manual

White

White 693 Series User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual