10

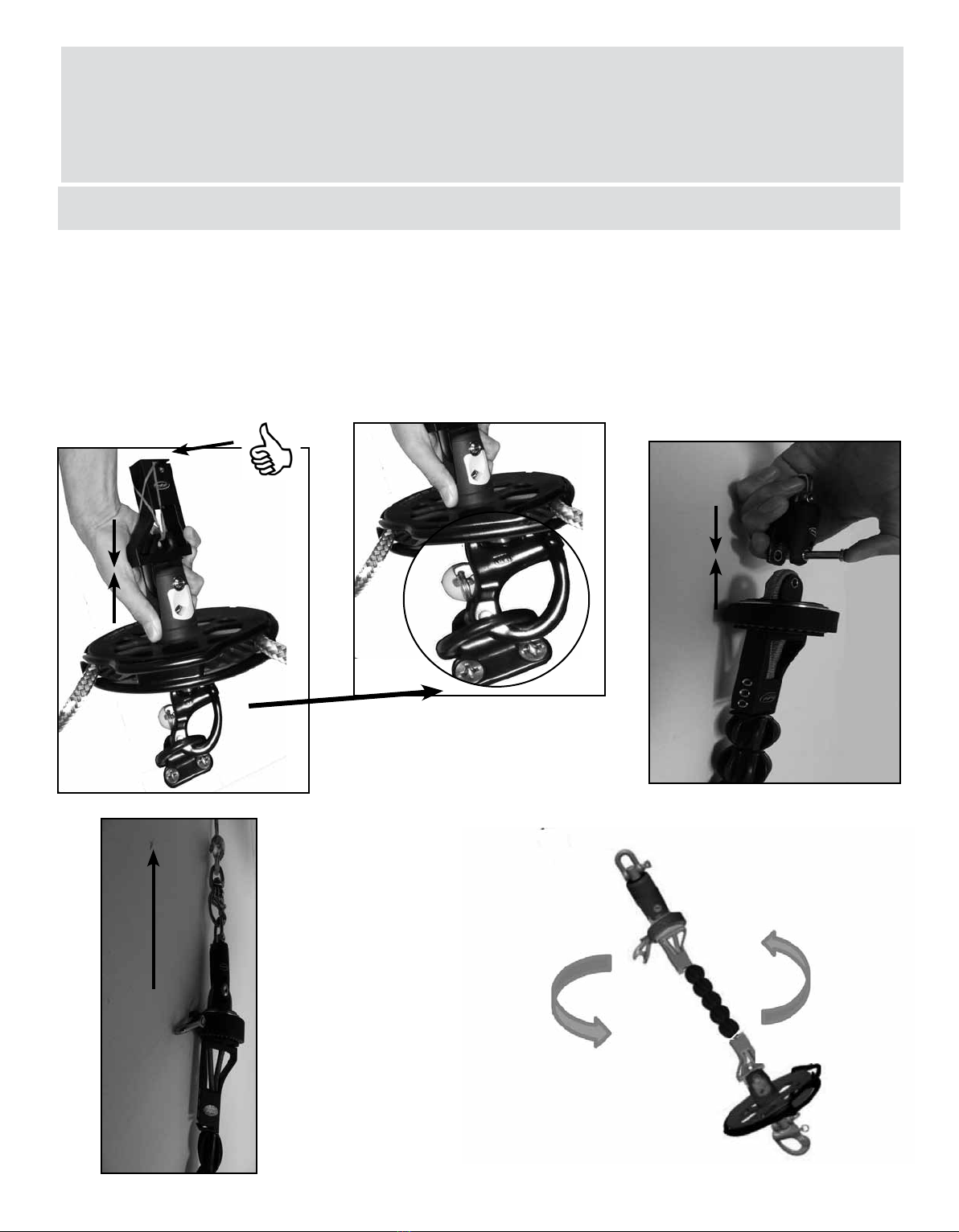

Etape 6 /Step 6

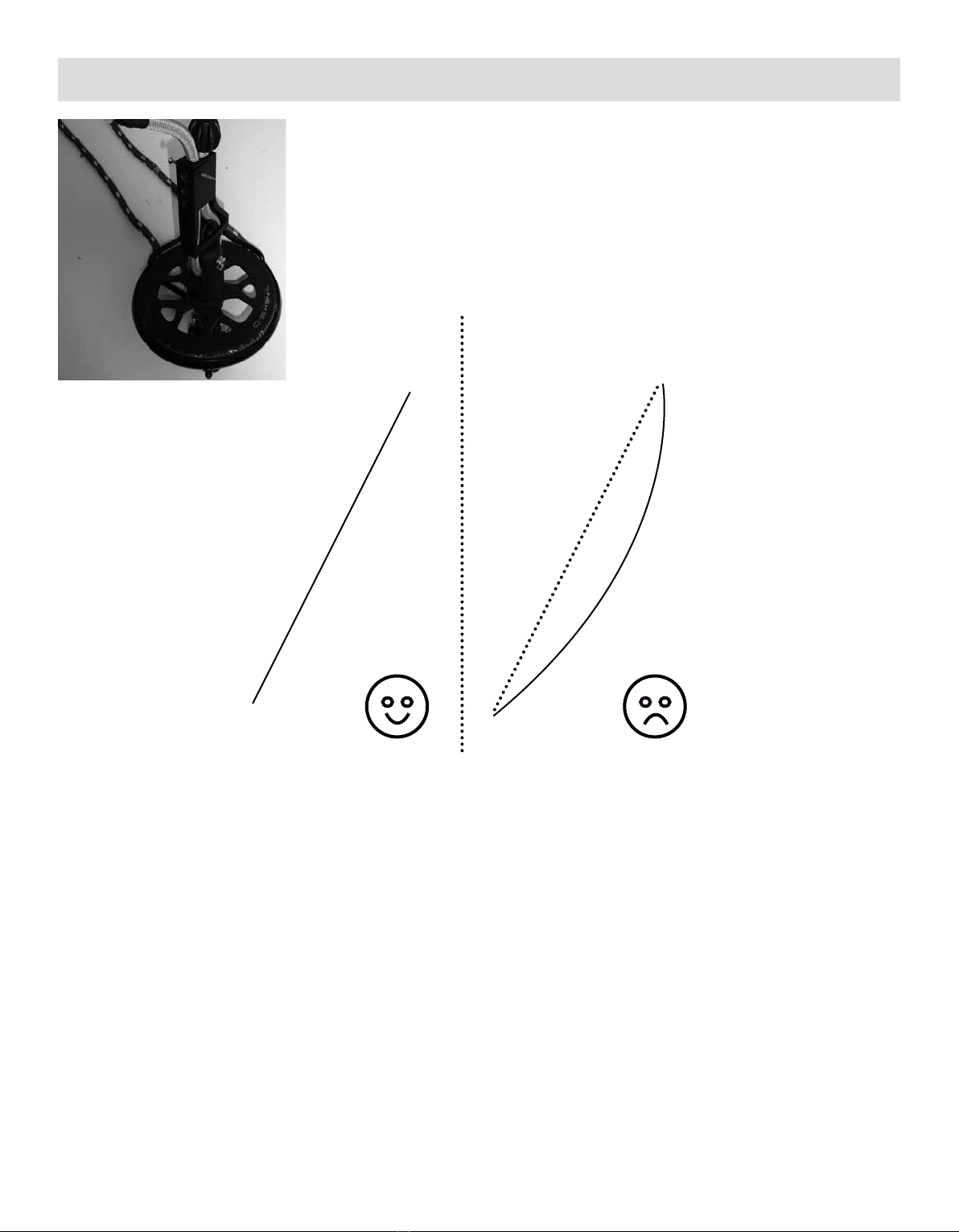

MISE EN PLACE DU SPINEX ET DE LA VOILE

SPINEX AND SAIL INSTALLATION

terminaison sur l’émerillon et le point d’amure libre sur le

mécanisme de tourelle.

Put the cable in its upright position.

Etape 6b /Step 6b

Attacher la tétiere de votre spinnaker .

Lash the head point of the sail to the

top tting.

Attacher le point d’amure directement

sur la manille pour un guindant

supérieur ou égal à 103% de la lon-

gueur du câble

Connect the tack point directly to the

shackle for sails with luff length equals

to 103% of cable length or greater

point d’amure pour un guindant de

spi entre 98% et 103% / à la longueur

du câble. Use a loop between the

shackle and the tack point for sailss

with luff length 98% to 103% of cable

length use a lashing.

d’amure pour un guindant de spi < à

98% .

For adjustable tack height use the

optional MX shackle for luff length

shorter than 98% of cable length.

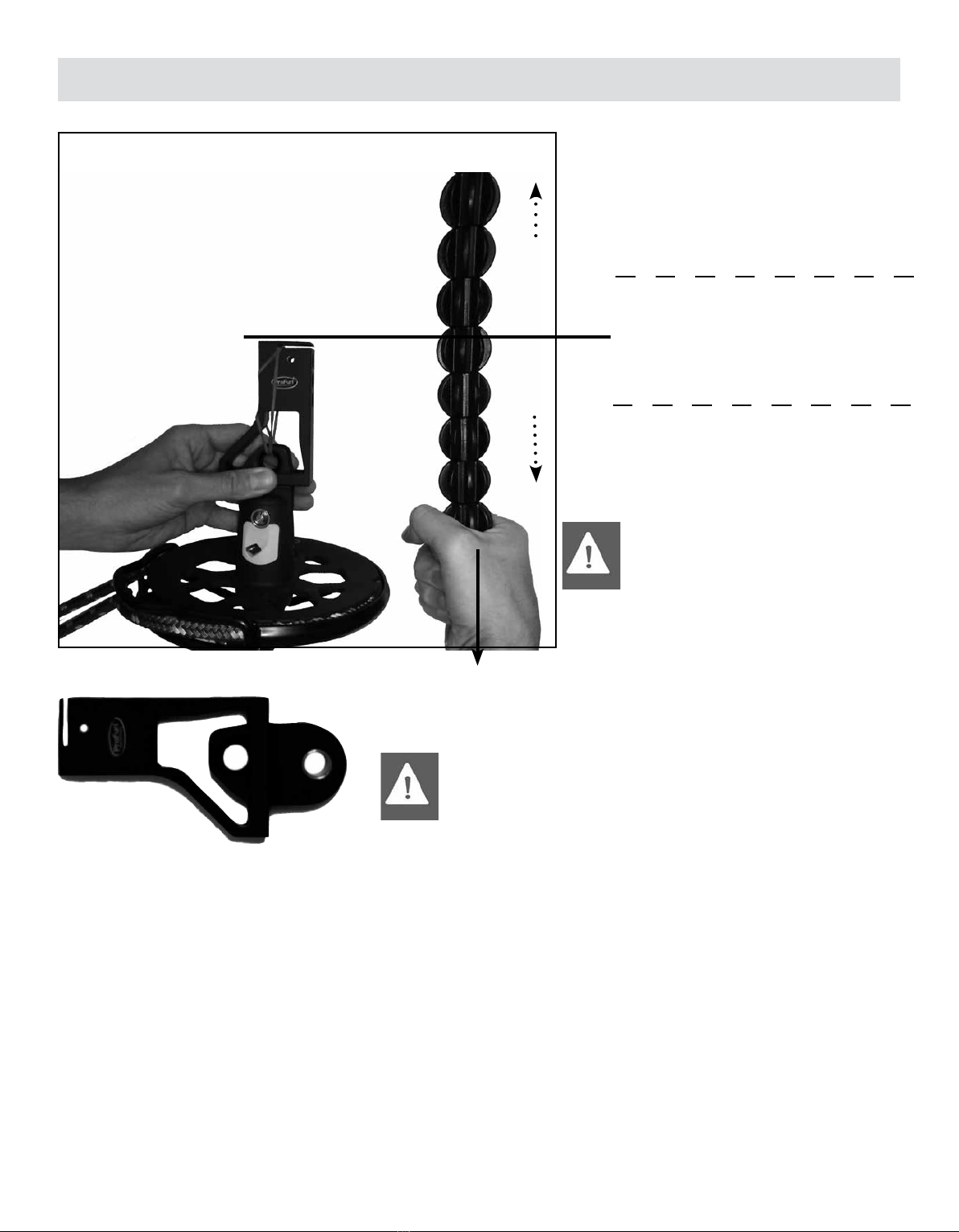

Attention l’estrope ne doit pas dépasser

90 cm et ne doit pas mettre en tension le

guindant de la voile.

Note the lashing must not be longer than

36 inches. Must not tension the luff of the

sail.

Il n’est pas necessaire de prendre de la

tension avant l’enroulement mais il est

important de relacher le point d’amure

it is not necessary to tension the line

before furling but it is necessary to

release the line to nish the furl