1

English

Table of contents

1. TO THE USER ...................................................................................................................................................................... 2

1.1 INTRODUCTION ...................................................................................................................................................................... 2

1.2 SAFETY PRECAUTIONS AND WARNINGS........................................................................................................................................ 3

1.2.1 Safety precautions .................................................................................................................................................... 3

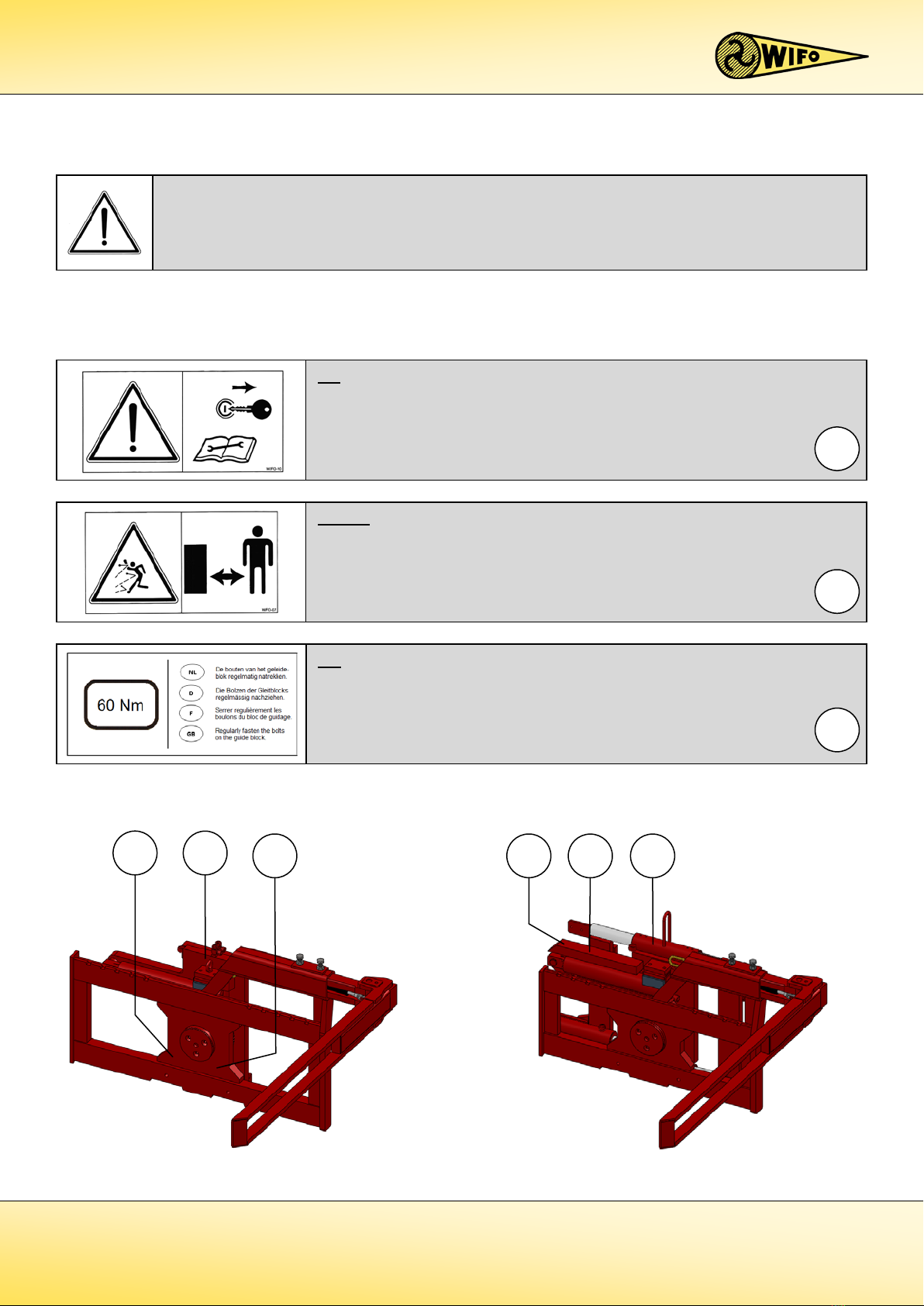

1.2.2 Safety stickers and warning signs............................................................................................................................. 5

1.2.3 Placement of the safety stickers on the machine ..................................................................................................... 5

1.3 PURPOSE OF USE .................................................................................................................................................................... 6

1.4 LIABILITY............................................................................................................................................................................... 7

1.5 WARRANTY ........................................................................................................................................................................... 7

2. TECHNICAL DATA .............................................................................................................................................................. 8

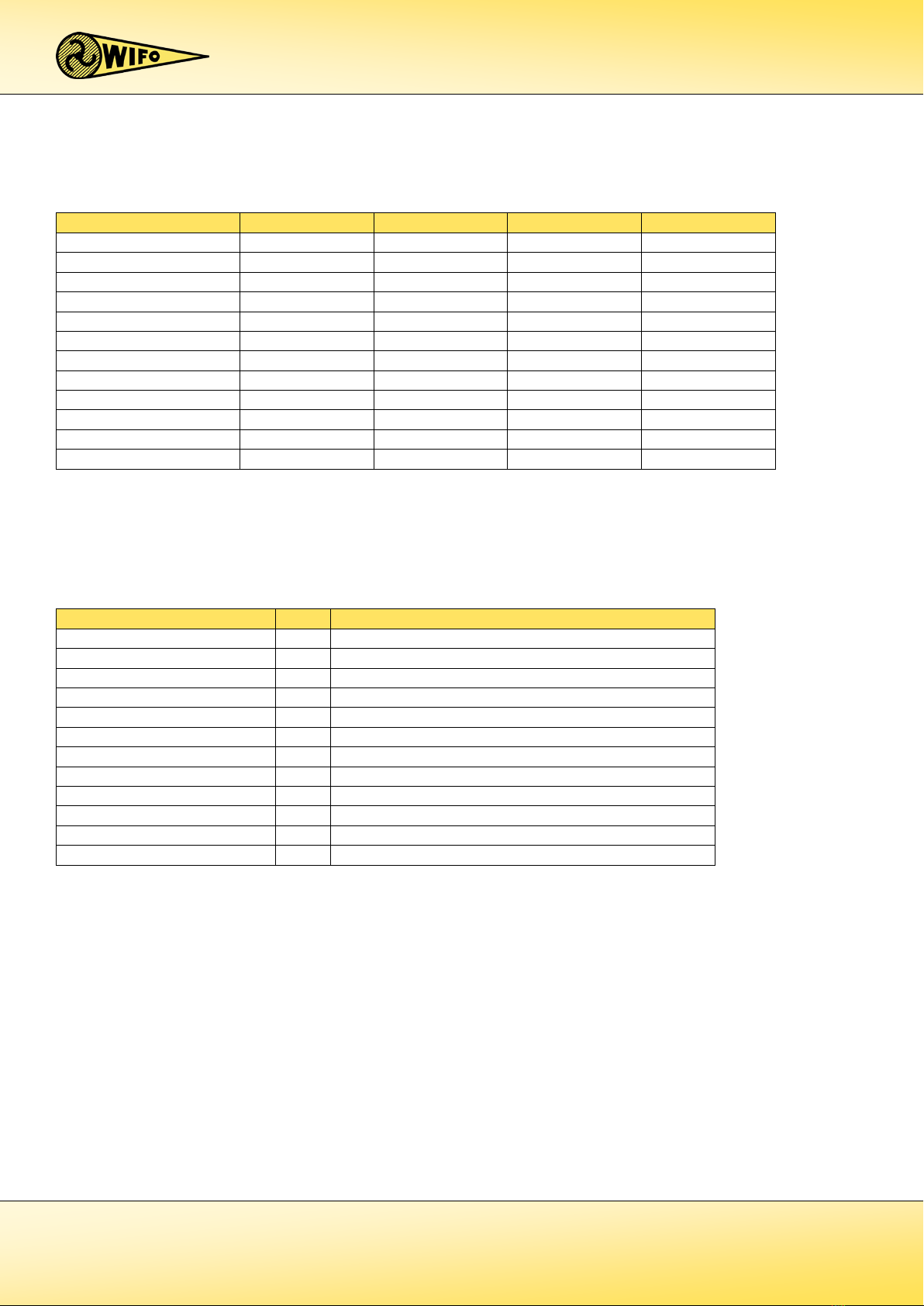

2.1 GENERAL TECHNICAL DATA...................................................................................................................................................... 8

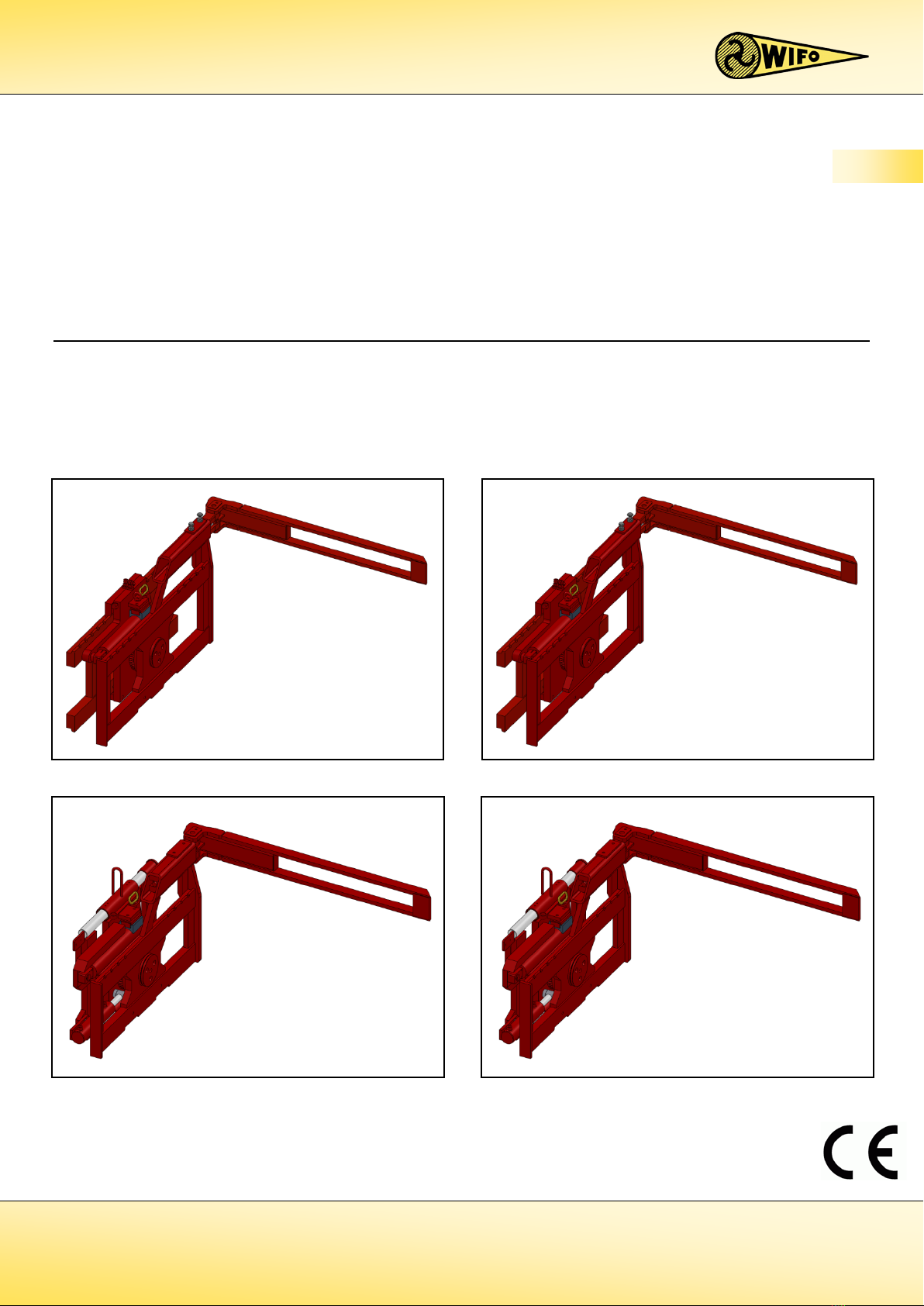

2.2 K53A AND K53C................................................................................................................................................................... 9

2.2.1 Parts list ................................................................................................................................................................... 9

2.3 K53A-Z AND K53C-Z (INDUSTRIAL MODEL)............................................................................................................................... 10

2.3.1 Parts list ................................................................................................................................................................. 10

2.3.2 Commencement of operation K53a-(z)/K53c-(z) .................................................................................................... 11

2.4 K53A-UK AND K53C-UK ........................................................................................................................................................ 12

2.4.1 Parts list ................................................................................................................................................................. 12

2.4.2 Commencement of operation K53a-uk/K53c-uk..................................................................................................... 13

2.5 DKB-25 AND DKD-35 ......................................................................................................................................................... 14

2.5.1 Parts list .................................................................................................................................................................. 14

2.6 DKB-25-Z AND DKD-35-Z (INDUSTRIAL MODEL)...................................................................................................................... 15

2.6.1 Parts list .................................................................................................................................................................. 15

2.6.2 Provisions for connecting DKB-25-(z)/DKD-35-(z) ................................................................................................... 16

2.6.3 Commencement of operation DKB-25-(z)/DKD-35-(z) ............................................................................................ 17

2.7 SPARE PARTS ....................................................................................................................................................................... 18

3. FAULTS AND MAINTENANCE ........................................................................................................................................... 19

3.1 PREVENTIVE MAINTENANCE AND LUBRICATION .......................................................................................................................... 19

3.2 TROUBLESHOOTING.............................................................................................................................................................. 20

3.3 WORK TO BE CARRIED OUT BY A COMPETENT MECHANIC.............................................................................................................. 21

3.3.1 Instructions for replacing the sleeve bearing of K53a/K53c/DKB-25/DKD-35 ........................................................ 21

3.3.2 Instructions for replacing the tapered roller bearings of K53a-z/K53c-z/DKB-25-z/DKD-35-z ............................... 22