Wiggens WH200D-1K User manual

OPERATING MANUAL

English

Digital Hot Plate

WH200D-1K / WH200D-2K / WH200D-3K

Room 303, Hall C, Office Building

M8, No. 1 Jiuxianqiao East Road,

Chaoyang District, Beijing 100015,

China

Tel: +86 400-809-2068

Fax: +86 400-809-2068-112

info@ wiggens.com

www.wiggens.com

Operating Manual

2

Congratulations!

You have made an excellent choice.

WIGGENS thanks for the trust you have placed in us.

This operating manual has been designed to help you gain an understanding of the

operation and possible applications of our instruments. For optimal utilization of all

functions, we recommend that you thoroughly study this manual prior to beginning

operation.

Declaration of conformity EN

We declare under our sole responsibility that this product corresponds to the

directives ……. and conforms to the following standards or normative documents:

EN ISO ……

The WIGGENS Quality Management System

ISO 9001

Certificate Registration No. 01 100084841

Unpacking and Inspecting

Please unpack the device carefully. Inspect them for possible damage. In the case of

any damage a damage report should be requested immediately. These instructions must

be followed fully for us to guarantee our full support of your claim for protecting against

loss from concealed damage. The form required for filing such a claim will be provided by

the carrier.

Printed in China

Changes without prior notification reserved

Important: keep operating manual for future use

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

3

Content

1. Intended Use...............................................................................................................4

2. Operator Responsibility...............................................................................................5

2.1 Disposal.................................................................................................................6

2.2 CE Conformity........................................................................................................6

2.3. Technical Specifications........................................................................................7

3. Safety Instructions.......................................................................................................9

3.1. Explanation of Safety Notes..................................................................................9

3.2. For your protection..............................................................................................10

3.3. For protection of the equipment..........................................................................12

4. Operating Procedures...............................................................................................12

4.1. Environmental Operating Conditions ..................................................................12

4.2. Installation...........................................................................................................13

4.3. Operation............................................................................................................15

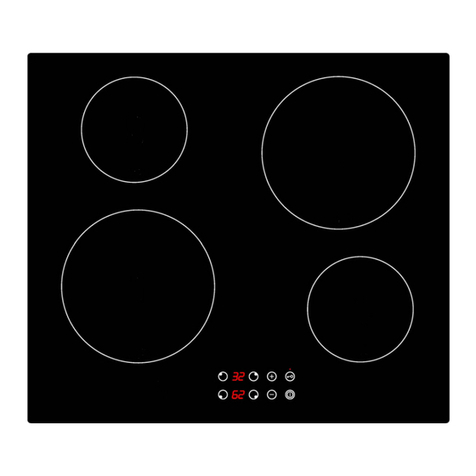

4.3.1. Overview of the Hot Plate.............................................................................15

4.3.2. Indicators and Functional Elements..............................................................16

4.3.3. Setting the Timer model................................................................................18

4.3.4. Operation of the Hot Plate without Temperature Sensor ..............................19

4.3.4 Operation of the Heater with a Temperature Sensor.....................................21

4.3.5. Using the RS232 Connection........................................................................24

5. Routine Cleaning, Maintenance, Transport, Storage, Trouble-Shooting...................25

5.1. Routine Cleaning ................................................................................................25

5.2. Maintenance .......................................................................................................26

6. Transport and Storage ..............................................................................................26

7. Accessories and Spare Parts....................................................................................27

7.1 Temperature Sensor and Holder..........................................................................27

8. Service......................................................................................................................28

8.1. Trouble-Shooting ................................................................................................28

8.2. Warranty .............................................................................................................28

8.3. Contact /Technical Service .................................................................................29

Operating Manual

4

1. Intended Use

The WH200D-1K / WH200D-2K / WH200D-3K Hot Plate is a heating plate with a

ceramic coated stainless steel top plate. It uses PID temperature control technology for

accurate and reliable results and is suitable for complicated temperature control

requirements. The LED screen can display both the set and actual temperature and the

value setting is easily done via a convenient on-touch control board. The Hot Plate

features a timer function for automatic heating of up to 100 hours and an alarm signal

and automatic stop function in case of over temperature situations. A PT100 temperature

sensor can be connected in order to provide direct and more precise control of the actual

temperature.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

5

2. Operator Responsibility

Use

- For heating liquids

Range of use

-Laboratories

-Schools

-Pharmacies

This device is suitable for use in all areas except:

- Residential areas

- Areas that are connected directly to a low-voltage supply network that also supplies

residential areas.

The safety of the user cannot be guaranteed

-if the appliance is operated with accessories that are not supplied or recommended by

the manufacturer or if the appliance is operated improperly contrary to the

manufacturer’s specifications.

The products of WIGGENS ensure safe operation when installed, operated, and

maintained according to common safety regulations. This section explains the potential

dangers that may arise when operating the instrument and also specifies the most

important safety precautions to preclude these dangers as far as possible.

The operator is responsible for the qualification of the personnel operating the

instrument.

The personnel operating the instrument should be regularly instructed about the

dangers involved with their job activities as well as measures to avert these

dangers.

Make sure all persons tasked with operating, installing, and maintaining the

instrument have read and understand the safety information and operating

instructions.

When using hazardous materials or materials that could become hazardous, the

instrument may be operated only by persons who are absolutely familiar with

Operating Manual

6

these materials and the instrument. These persons must be fully aware of

possible risks.

Only qualified personnel are authorized to perform configuration, installation,

maintenance and repairs of the instrument.

Routine operation can also be carried out by untrained personnel who should

however be instructed by trained personnel.

If you have any questions concerning the operation of your instrument or the information

in this manual, please contact us!

2.1 Disposal

At the end of its service life the instrument is to be disposed of in

accordance with the local regulations specified for the disposal of

electronic industry waste in an environmentally friendly manner.

2.2 CE Conformity

The products described in the operating instructions conform to the

requirements of the following European guidelines:

Low voltage regulations with respect to legal harmonization of the

member countries concerning electric devices for use within certain

voltage limits.

EMC guideline with respect to legal harmonization of the member

countries concerning electromagnetic compatibility.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

7

2.3. Technical Specifications

Model

WH200D-1K

WH200D-2K

WH200D-3K

Display Mode

LED

Indicating Accuracy

F.S ±1%

Temperature Stability

±0.2°C

Temperature Range

50~300°C with Surface Temperature Control

40~300°C with External Sensor Control

(Setting Resolution 1°C)

Temperature Sensor

Inner Sensor: Thermocouple K(CA)

External Sensor: PT 100 probe

Power Supply

220V AC, 50Hz

Allowable Voltage Range

(90~110% of the Power Supply)

Heater Capacity

Approx.680W

Approx.1000W

Approx. 1500W

Safety Device

Thermostat, Circuit Protection

Control Method

On / Off Control, PID control

Connection Method

RS-232

Proportional Band Width(P)

0.0~100.0%

Integral Time (I)

1~9959min

Differential Time (D)

1~9959min

Sampling Cycle

0.5 sec

Ambient Temperature

5~35°C

Weight

2.8 kg

5 kg

7 kg

Dimension (W×L in mm)

170×170

320×320

400×300

Basic Order Number

400110

400111

400112

All measurements have been carried out at the stated voltage, frequency, and an

ambient temperature of 25°C.

Technical changes without prior notification reserved.

Operating Manual

8

WIGGENS Order Numbers consist of the Basic Order Number (BON)

and the Order Number Addition (ONA) which explains different

characteristics of the product that can vary from country to country. Order

Numbers as stated on the product label and box label are stated as Full

Order Numbers (FON), consisting of the BON followed by the ONA. For a

full explanation of the ONA of your product, please ask your local

WIGGENS support or refer to the Order Number Guide in the WIGGENS

General Catalog.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

9

3. Safety Instructions

3.1. Explanation of Safety Notes

In addition to the safety warnings listed, warnings are posted throughout the operating

manual. These warnings are designated by an exclamation mark inside an equilateral

triangle. “Warning of a dangerous situation (Attention! Please follow the

documentation).”

Follow the safety recommendations to prevent damage to persons or property.

Further, the valid safety instructions for working places must be followed.

Symbol

Additional term / Description

Warning signs

The danger is classified using a signal word. Read and follow these

important instructions for averting dangers.

Warning!

Describes a possibly highly dangerous situation. If these instructions

are not followed, serious injury and danger to life could result.

Caution!

Describes a possibly dangerous situation. If this is not avoided, slight

or minor injuries could result. A warning of possible property damage

may also be contained in the text.

Notice!

Describes a possibly harmful situation. If this is not avoided, the

product or anything in its surroundings can be damaged.

Note!

Draws attention to something special.

Operating Manual

10

Important!

Indicates usage tips and other useful information.

3.2. For your protection

Make sure you read and understand all instructions and safety precautions listed in

this manual before installing or operating your instrument.

Keep the operation instructions in a place where they can be accessed by everyone.

Make sure the product is checked for proper condition regularly (depending on the

conditions of use). Regularly check (at least every 2 months) the proper condition of

the mandatory, warning, prohibition and safety labels.

Connect the instrument to a power socket with earthing contact (PE-protective

earth)!

The power supply plug serves as a safe disconnecting device from the line and must

always be easily accessible.

Do not stay in the area below the instrument.

Never operate damaged equipment.

Never operate instruments with damaged mains power cables.

Observe all warning labels.

Never remove warning labels.

Be aware of tripping! Never route the connection cable in highly frequented areas!

Be aware of possible cable damage! Keep the connection cable away from the

heating zone!

Repairs are to be carried out only by qualified service personnel

Always turn off the instrument and disconnect the mains cable from the power

source before performing any service or maintenance procedures, or before moving

the instrument.

This is not an explosion proof instrument. Do not use with any

highly flammable or explosive materials.

Never operate the hot plate in wet areas!

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

11

Be aware of the danger of electric shocks!

Be aware of the potential danger of a fire outbreak due to

overheating!

Wear your personal protective equipment in accordance with the

hazard category of the media to be processed. Otherwise there is a risk from:

- Splashing and evaporation of liquids

- Ejection of parts

-Release of toxic or combustible gases.

When in an emergency, disconnect the main power plug.

Beware of hazards due to:

- Flammable materials

- Combustible media with a low boiling temperature

- Glass breakage

- Incorrect container size

- Overfilling of media

- Unsafe condition of container.

Process pathogenic materials only in closed vessels under a suitable extractor hood.

Only process media that will not react dangerously to the extra energy produced

through processing. This also applies to any extra energy produced in other ways,

e.g. through light irradiation.

Please observe the operating instructions for any accessories used.

Never operate the hot plates on home furniture!

For safety reasons place the digital hot plates at least 50 cm from any inflammable

material!

Never operate the hot plate on home furniture!

Appropriate safety clothing, glasses, gloves and coats should be worn when

operating hot plates. Always use appropriate hand and eye protection when handling

hazardous chemicals.

Do not use with flammable or combustible chemicals; the top surface and elements

Operating Manual

12

can reach the flash point temperature of many chemicals

Do not plug or unplug power cord with wet hands. Such action can cause electric

shock.

Be aware of possible cable damage! Keep the connection cable away from the

heating zone!

3.3. For protection of the equipment

You have received a product designed for industrial and experimental use.

Nevertheless, avoid strikes to the housing, vibrations, damage to the

operating-element panel, and contamination.

Make sure that the mains power supply has low impedance to avoid any negative

effects on instruments being operated on the same mains.

Do not expose the unit to sunlight

Sudden drops may cause damage in the interior of the instrument.

Transport the instrument with care.

The device can be damaged when sucking in aggressive gases or vapor through the

installed ventilator!

Press the power button to interrupt the hot plate, rather than disconnect the main

power plug directly.

Ensure that the base plate is kept clean

Never operate the hot plates in wet areas!

Be aware of the potential danger of a fire outbreak due to overheating!

Press the power button to interrupt the hot plate, rather than disconnect the main

power plug directly.

4. Operating Procedures

4.1. Environmental Operating Conditions

The Hot Plate must operate in the following conditions:

Indoors

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

13

Altitudes up to 2000 meters

Temperatures from +5°C to +40°C

Maximum relative humidity 80% for temperatures up to +31°C, linear decrease down

to 50% relative humidity at a temperature of +40°C

Max. mains fluctuation of ±10 % are permissible

Protection class according to EN 60 529: IP31

The unit corresponds to Class I

Overvoltage category II

4.2. Installation

Place the hot plate on a stable, flat surface and proper environment for operation.

If a PT100 temperature sensor package was ordered:

Install the sensor holder into the screw inlet on the back of the hot plate

Mount the Pt100 temperature sensor on the holder

Connect the PT100 temperature sensor cable to the corresponding connector in

the back of the hot plate

Connect the hot plate to a power socket with earthing contact.

Operating Manual

14

Caution:

Do not use voltages that are higher or lower than 10% of the

voltage specified on the label, which is on the backside of the

instrument.

Keep the power cord and temperature sensor cable off of the hot

plate while heating.

Put the solution on the top plate before operating the instrument.

Heating corrosive liquids under poor ventilation hoods will

shorten the life of the electronic components inside the

instrument.

Upon the first heating operation, a particular smell and white

smoke can appear. This is normal. Put the instrument under a

fume hood and moderately heat for about one hour until the

smell and smoke fully disappear.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

15

4.3. Operation

4.3.1. Overview of the Hot Plate

No.

Description

1.

PT100 Temperature Sensor

2.

Top Plate

3.

Operation Panel

4.

LED Display

5.

Instrument Housing

6.

Boss Head Clamp

7.

Support Bar

Operating Manual

16

4.3.2. Indicators and Functional Elements (WH200D-1K)

No

Icon

Description

1

LED Display

Shows the set temperature, actual temperature, and timer

settings

2

Power

Indicates that the instrument is powered on

3

Start

Indicates that the heating process has started

4

Alarm

Indicates that an alarm occurred

5

Hot Top

Indicates that the top plate has reached a temperature that

could lead to burning injuries

6

Set Temp

Indicates that the display shows the set temperature

7

Pro Temp

Indicates that the display shows the actual temperature

8

OFF-Time

Indicates that the display shows the timer in OFF-Time mode

9

WAIT-Time

Indicates that the display shows the timer in WAIT-Time mode

10

START / STOP Button

Press the START / STOP Button to start / stop the instrument.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

17

11

SELECT Button

Press the SELECT Button to toggle between the operating

modes: Set Temp, Pro.Temp, OFF-Time, and WAIT-Time. The

LED light indicator will change accordingly.

12

Up Button

Press the Up Button to increase the temperature or time value

in the setting modes.

13

Down Button

Press the Down Button to decrease the temperature or time

value in the setting modes.

14

CLEAR Button

The button clears up all set values and sets them to 0. The

timer is set to continuous mode.

Note!

All WH series digital hot plates are use the totally same operation

method

Caution!

Do not use voltages that are higher or lower than 10% of the

voltage specified on the label, which is on the backside of the

instrument.

Keep the power cord and temperature sensor cable off of the hot

plate while heating.

Put the solution on the top plate before operating the instrument.

Heating corrosive liquids under poor ventilation hoods will

shorten the life of the electronic components inside the

instrument.

Upon the first heating operation, a particular smell and white

smoke can appear. This is normal. Put the instrument under a

Operating Manual

18

fume hood and moderately heat for about one hour until the

smell and smoke fully disappear.

4.3.3. Setting the Timer model

The hot plate has three kinds of working modes: Continuous Mode, OFF-Time Mode,

and WAIT-Time mode. When the timer is set to zero, the LED screen will display “OFF”.

The maximum time that can be set is 99:59, the left two numbers indicate the hour(s),

and the right two numbers indicate the minute(s).

Continuous Mode

When both OFF-Time and WAIT-Time are in the “OFF”

state, the unit is working in continuous heating mode.

OFF-Time Mode

When the WAIT-Time is set to “OFF”, and the OFF-Time

mode is not set to OFF, the hot plate will operate in the

OFF-Time mode. It starts to heat when the START /

STOP Button is pressed, and stops when the time

reaches the set time.

WAIT-Time Mode

When the WAIT-Time is not zero, regardless of whether

the OFF-Time is set to “OFF” or not, the hot plate will

operate in the WAIT-Time mode, which will start the

timer from the point when the actual temperature has

reached the set point temperature, When the set time is

reached, the heating will stop automatically.

WIGGENS WH200D-1K / WH200D-2K / WH200D-3K

19

4.3.4. Operation of the Hot Plate without Temperature Sensor

1. Setting the Temperature

Switch the main power button on

Press the SELECT Button until you have reached the Set Temp Indicator

Select the desired temperature by pressing the Up Button to increase or

Down Button to decrease the set temperature

By holding the Up Button / Down Button the set temperature increases /

decreases in higher increments

2. Setting the Timer

Press the SELECT Button until you have reached the OFF-Time Indicator /

WAIT-Time Indicator

Select the desired time by pressing the Up Button to increase or Down

Button to decrease the set time

By holding the Up Button / Down Button the set time increases / decreases

in higher increments

Press the Down Button until the display shows OFF in order to switch off

the timer and to work in continuous mode

Operating Manual

20

3. Starting / Stopping the Heating Process

Press the SELECT Button until you reach the Temp Indicator in order to

monitor the actual temperature

Press the START / STOP Button to start the heating process

Press the START / STOP Button again to stop the heating process or wait

for the timer to stop the heating process automatically (if not in continuous

mode)

CAUTION! Risk of burning! Do not touch the heating zone!

CAUTION! Residual heat! Do not touch the heating zone!

CAUTION! Risk of overheating! Do not pull out the mains plug!

CAUTION! Do not unplug and turn off the mains of the hot plate

before the heating zone has completely cooled down. Turn off the

mains switch and pull out the mains plug after the top plate has

reached a safe temperature.

This manual suits for next models

2

Table of contents

Popular Cooktop manuals by other brands

Blue Seal

Blue Seal G57 Installation and operation manual

Frigidaire

Frigidaire FGEF3034K W Important safety instructions

GE

GE JP202DWW Owner's Manual & Installation Instructions

Electrolux

Electrolux EI36EC45KB1 installation instructions

Franke

Franke FH 604-1 4I T PWL Instructions for use and installation

Euromaid

Euromaid I3B60 user manual