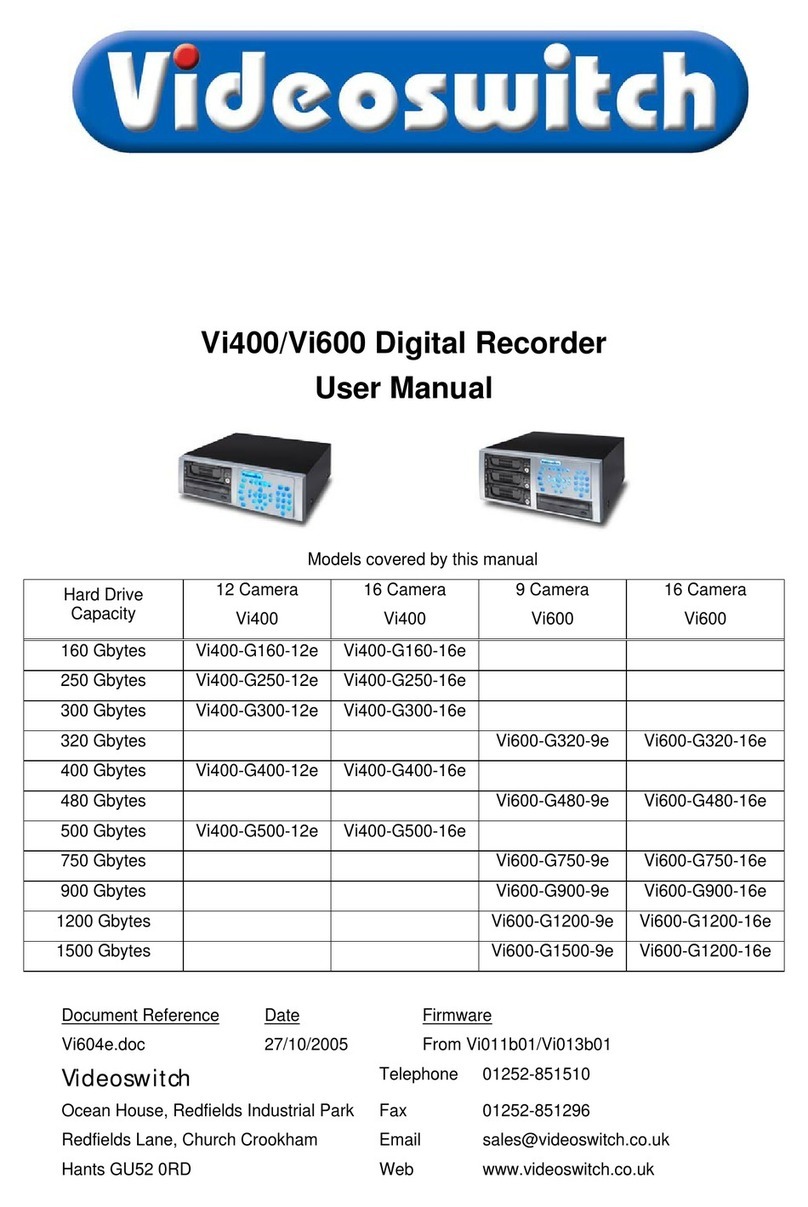

Wilcox-Gay 3F10 User manual

H*toroFAcr* FolJ.t

ffi

ffi

RADIO-PHONO

TV

INPUT

RECORDING

INDICATORS

RfVERSE

AC LINE

CORD

RECEPTACLE

RECORD EXTERNAL

SPEAKER JACK

FORWARD VOLUME CONTROL

ON-OFF SWITCH

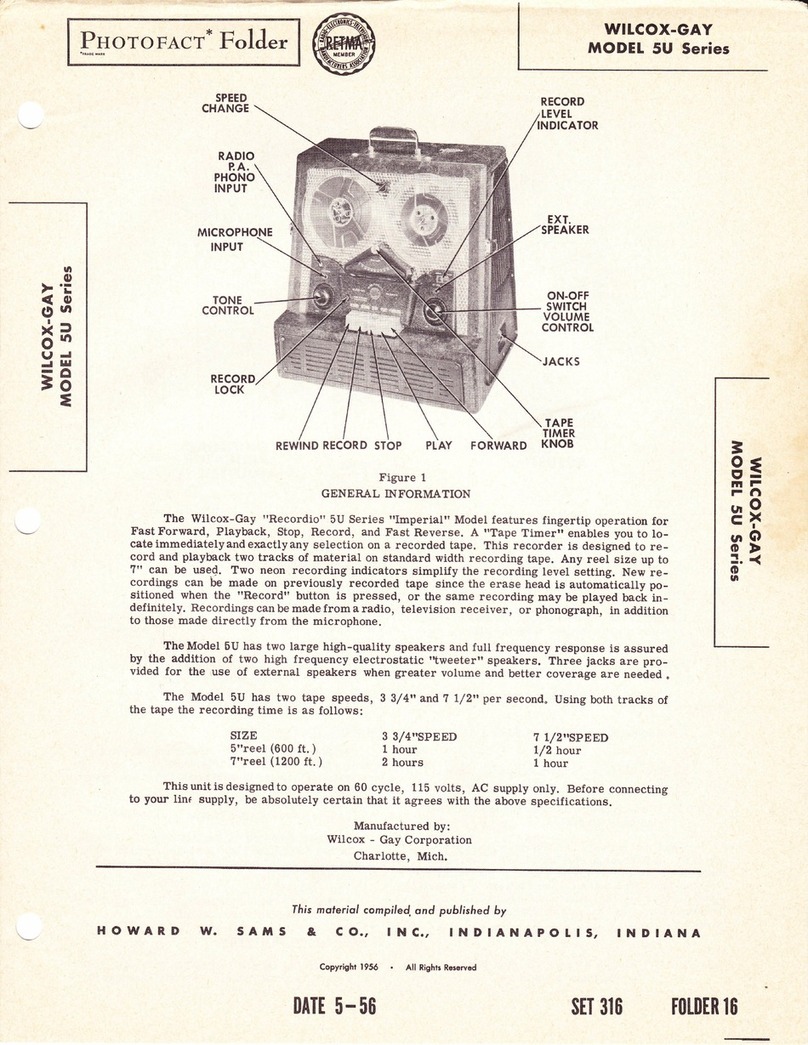

GENERAL INFORMATION

The Wilcox-Gay "Recordio" Model 3FI0 features fingertip operation f or Fast Forward, Play-

back, Stop, Record and Fast Reverse. The "Recordio" is designed to record and play back two

tracks of material on standard width recording tape, which doubles the playing time of a standard

5" or ?" reel of tape with no loss of frequency response or quality. Recordings can be made

from a radio, television receiver or phonograph, in addibion to those made directlyfrom the

rnicrophone. Recordings can be played back through the seU-conbained speaker or an external

speaker through use of the Auxiliary Speaker Jack.

This "Recordio" has two tape speeds, 7 l/2" and 3 3/4" per second. Using both channels of the

tape, the recording time is as follows:

MIKE

lf'{FUT

ie

qs

X-r

8x

ro

==

={

OF

H8

ry

*f,

6l

SIZE

5" reel

?t'reel

SPEED

3-3/ 4

t hour

2 hours

SPEED

7-r/2

1/ 2 hour

t hour

The 3FI0 is designed to operate on 60 cycle, ll5 volt, AC supply.

CAUTION: Severe Damage WiII Result if Connection is Made to a Direct Current (DC) Line.

Manufactured by:

Wilcox-Gay Corporation

Brooklyn, N. Y. Charlotte, Mich.

wttcox-GAY

MODEL 3FIO

fhis moleriol compiled ond published by

SAMS & CO., lNC., INDIANAPOIlS,

Copyright 1953 ' All Rights Reserved

DATT II-5 3

INDIANA

srT 22 0t0tDER ll

HOWARD \/.

./-'-- . /:\

J8)

,:lffi \J

Figure 2.

OPEFATING INSTRUCTIONS

I. With the "Stop" button depressed, insert the

AC power cord into the receptacle at the right side

of the cabinet (Figure I).

2. Plug the AC cord into a convenient wall

receptacle of the proper rating.

Threading the Tape -

I. Place a reel of tape on the left spindte (a)

and an empty reel on the right spindle (8) making

surethe reel slots engagethe reelpin on thespindles.

2. Unwind about 14" of the tape from the reel.

HoId a section of the tape straight with both hands

and insert the tape in the tape slot making sure the

dull coated side of the tape f aces the rear of the

recorder.

NOTE: This recorder u s e s Type "A" wound tape,

i. e. the dull magnetic coated side faces in-

ward on the reel. If the tape to be used is

Type "B" (coated side facing outward) place

the reel on the left spindle so that the tape

will lead-off in a clockwise direction. Bring

the tape behindthe rear cover (5)(not

through the head slot) and thread it on to the

right reel in the normal manner. Press the

"Forward" button and allow the full reel of

tape to wind on the empty reel. The duII

side of the tape wiII now be facing inward on

the reel.

3. Insert the free end of the tape through the

hub of the right take-up reel and place a pencil

firmly over the tape, forcing it into one of the three

Page 2

radial slots on the hub of the empty reel. Turn the

reel several turns with the pencil in this position

until the tape is secured to the reel and all slack is

taken up between the reels.

To Record From Microphone -

I. Turn the On-Off Volume Control to the right

until a click is heard and allow about thirty seconds

for the unit to warm up. The pilot light located

above the "Stop" button will glow when the unit is

turned on.

2. Insert the microphone plug into the "Micro-

phone Input Jack".

3. Turnthe speed control knob(I)to the deslred

speed.

NOTE: Recordings made at a certain speed must be

played back at that speed.

4. Move record lock Iever (18) downward with

the left hand. This releases the record safety lock

which prevents accidental erasure.

5. Depress the "Record" button with the right

hand (while holding the record lock lever (I8) with the

Ieft hand) until it latches.

6. Whiie talking into the microphone, adjust

the "Volumen control until the "Normal" indicator

f.Iashes and no flashing occurs at the "Overload"

indicator.

NOTE: Correct recording volume is very important.

Too weak a signal, which does not cause the

"Normal" indicator to flash, will re sult in

weak playback and high background noise.

fl!%'';.'r.

Figure 3.

Too strong a signal, causing the "Overload" NOTE: Should a hum develop from the above con-

indicator to flash, wiII result in distortion nection, reverse the cord clips on the pick-

during playback. up leads.

To Record From External Radio -To Record From Television Receiver

3{

OF

H8

r;1

H6t

6l

Recordings can be rnade from a radio by placing the

microphone near the loudspeaker of the radio;

howeve r, this type of recording may not be satis-

factory as other sounds may be picked up by the

microphone which as a result wiII be recorded on the

tape. A superior quality recording can be rnade by

use of radio-phono attachment cord (Part No.

C-20.233). Connect attachment cord as follows:

I. Connect the cord clips across the voice coil

terminals on the radio speaker as shown in

Figure 4.

2. Insert the cord plug into the "Radio, TV,

Phono Jack".

3" Proceed as described in "To Record From

Microphone".

NOTE: Remove attachment cord after recording is

completed.

To Record From Phonograph -

I. Connect the cord clips of the attachment

cord to the pickup leads on the external phonograph.

2. Insert the attachment cord plug into the

"Radio, TV, Phono Jack".

3. Proceed as described in "To Record From

Microphone".

I. Connect attachment cordas describedin

"To Record From External Radio" and proceed with

recording as described in "To Record From Micro-

phone".

NOTE: The "Recordio" Tone Control does not oper-

ate during recording. When recording from

radio or a television receiver set the radio

or television tone control for maximum

treble.

DuaI Track Recording -

The Recordio is designed so that L/ 2 the tape width

is recorded at a time; thereby resultingin two

track recording. This two track operationis

accomplished in the following manner:

I. After a reel of tape has been recorded,

i. e. all of the tape wound on to the take-up

reel, depress the I'Stop" push button. This

stops all movement of the tape.

2. Remove the reels from the recorder,

turning the fuII reel over and placing it on the

Ieftspindle andthe empty reel onthe right

spindle.

3. Properly thread the tape and proceed with

the recording as in I'To Record F r o m Micro-

phonett.

Page 3

Figure 4.

4. After this track has been recorded the

f i r s t track of recording is ready to be played

without rewinding.

(a) Place the futl reel of tape on the feed reel

(lef t) spindle and the empty reel on the

take-up (right) spindle.

(b) Thread the tape making sure the duII side

of the tape faces the record head.

(c) Set the controls as described under "To

Play a Recording".

To PIay a Recording -

1. Thread the tape as described under

"Threading the Tape".

2. Turn the On-Off Volume control on and

allow thirty seconds for the tubes to warm up.

3. Depress the "Play" button until it is

Iatched into position.

4. Adjust the Volume and Tone control to suit.

-

Any size speaker of the permanent magnet type,

having a 3 ohm voice coil, may be used by connecting

a speaker extension cord acorss the voice coil of the

speaker and then inserting the extension plug (same

type as micorphone plug) into the External Speaker

Jack located on the r i g h t side of the cabinet. This

automatically cuts out the seU-contained speaker.

To Edit and Splice Tape -

NOTE: Since it is impossible to edit and splice

one track without affecting the other, re-

cordings which a r e to be edited should be

Iimited to one track only.

I. T h e tape may be edited by cutting out un-

wanted portions, or by joining selections into an-

othe r sequence. Announcements m ay be inserted

Page 4

betweenselections, etc. Unused sections of tape

can be spliced together for re-use,

2. For best results, cut tape at a slight di-

agonal, join ends together with splicing tape on the

glossy side and trim off any excessive width.

Fast Forward and Fast Rewind -

High-speed forward or reverse wind can be obtained

by pressing the desired button. These are used

primarily in locating a desired portion of a record-

ing in a few seconds.

CAUTION:The "Stop" button should always be de-

pressed before changing functions or

speeds. AIways depress the "Stop" but-

ton when the Recordio is not in use.

Erasing Recorded Material -

Erasing of recorded material takes place auto-

matieally when new material is recordedl there-

fore, no special step is necessary to erase

recordings before new recordings are made. How-

ever, if a portion of a recording or an entire reel

of tape is to be completely erased, do so as follows:

1. Properly thread the tape on the rn a c h i n e .

2. Turn the Volume control knob clockwise

until a click is heard. This turns the recorder

on.

3. P r e s s down on the Record button until it

Iatches into position. The erasing of recorded

material is now in process and may be stopped

at any time by depressing the "Stop" button.

NOTE: OnIy one track of recorded material is

erased at a time. To erase the second

track, reverse the reels and repeat the

above operation.

To Use Recorder as a Public Address System -

The recorder may be used for public address with

or without recording the material at the same time.

Plug in an external speaker asdescribedin"To

Use an External Speaker". Turn the recorder on

and depress the Record button, but do not use tape.

Be caref ul to maintain sufficient distance between

the microphone and the external speaker to prevent

feedback howl. ffitis desired to record thepro-

gram, thread the tape as previsouly described

before depressing the Record button.

ADJUSTMENTS

Disassernbly Instructions -

I. Remove two Phillips head screws from

rear of case.

2. Remove push-on type volume and tone

control knobs.

3. Remove two screws located under volume

and tone control knobs. Remove escutcheon.

----l

\\ '..

\\

\\ -":"r

\'-- -"dr.f

' ""** -{

gg

e*t I

4. Remove two hex head screws located

under escutcheon. pad away from the tape. The test should be made

onthe end of the pressure pad mounting spring (3?).

Adjust the pressure padfor l-3/4 oz" +L/4 oz.

Figure 5.

leads from pressure.

=€

OF

H8

Fx

So

6l

5. Lift unit out of case, removing

speaker before removing unit completely.

Record-PIay Head Adjustment

To adjust the record-play head (28) for maximum

frequency response, make the following adjustment:

t. Remove the rear cover escutcheon (5).

2. Properly thread an alignment tape or a

good recorded tape on the machine.

3. Set the controls as described under "To

PIay a Recording".

Grip the vertical portion of the record head mount-

ing bracket with a p a i r of long-nosed pliers. Rock

the mounting bracket and record head f rom side to

side slightly until the maximum high frequencies are

obtained. Bend the bracket with the pliers to obtain

a permanent set at this position.

4. Replace the rear cover excutcheon (5).

Pressure Pad Adjustment (See Exploded View) -

I. Remove the front and rear escutcheons

(5 and lI).

2. Depress

the recorder on. the "Play" button. Do not turn

(a) The record-head pressure pad is adjusted

by the locked adjustment screw (44).

(b) The guide post pressure pad (43) is ad-

justed by bending the pressure pad spring.

It must be adjusted for minimum pres-

sure against the tape.

4" After the adjustments are made depress

the "Stop" button and replace the trim covers.

Erase Head Adjustment -

I. With tape properly threaded, turn recorder

on and depress the Record button. Allow tape to run

for a few seconds then turn recorder off, but leave

Record button depressed.

2. With the trim covers removed check the

erase head (120), see Figure 2, to see if it is

parallel withthe tape, if notloosen screw (22)

just enough so the head can be pivoted and align it

with the tape then tighten the screw.

CAUTION: Make sure the head retracting spring

(24), see Figure 6, remains in f ront of

the erase head while adjusting it.

3. Check to see if the top edge of the tape

coincides with the top end of the diagonal slot in the

erase head (junction of long diagonal slot and short

vertical slot). To adjust level of tape, Ioosen lock

nut (20), see Figure 6, and rotate tape guide post

(2I) to move tape up or down. Tighten lock nut (20).

3. Use a pencil type postal

the am ount of pressure necessary scale anri check

to just pull the

Page 5

4. Af ter this adjustment has been made,

check to see if the tape moves forwardapproximately

I/64" when the "Recordtt button is depressed, if

not, loosen the forward adjustment screw (23) and

turn the screw in or out as required to obtain this

/64" adjustment. Tighten the lock nut.

5. Replace the trim covers.

Brake Shoe Adjustment - (See Figure b)

I. In order to adjust the brake shoes, the

complete mechanism must be removed from the

carrying case and the speaker disconnected.

2. With all push buttons in the up position

the brake shoes (70) should clear the drums by

approximately l/ 8,,.

3. Depress the "Stop" pushbutton while observ-

ing the brake shoes. Both brake shoes must contact

the drums at the same time and with equal pressure.

4. The ailjustment is accomplished by b e n d -

ing the spring arm (69).

Adjustment for Slow Take-Up Reel-

There are some instances where the spring drive belt

(9), see Figure 5, stretches aJter a periodbf time. In

this case, the belt should be removed and shortened.

Somebelts haveloops whichare joined toform thecon-

tinuousbelt. See Notebelowregarding shortiningbelt.

NOTE: The spring belt is made so that one end will

twist into the tip of the other endl therefore,

clip the turns off the large end of the belt.

1. Clip off 3 to 5 turns of the spring belt.

2, Twist the ends together and replace the belt.

Bias Adjustment-

Turn the recorder on and depress the "Record" but-

tonl use no tape. To determine if the b i a s is within

satisfactory limits without dismantling the unit, merely

connecta VTVM from the toplug of therecording head

to the chassis. If 75 to 100 volts are present no ad-

justment is necessary.

If the readings are outside of thi s range, proceed as

follows:

l. Try a new I2AY7, IZA)K?,6Ae5 and by3.

2. If still not within range, remove the chassis

shield and connect a low capacity VTVM from

Pin 2 of V2 to the chassis and ad just trimmer

M5 (see Figure 8) to obtain a reading of 2.2b

volts. This provides the optimum in perfor_

mance.

TROUBLES

Push Buttons Fail to Latch into position -

1. Spring (41) loose or broken, resulting in the

erase head (120) not being pulled forward to engage

the tape. See Figure 2.

2. Erase head not aligned properly. See

ItErase Head Adjustmenilt.

No Fast Forward or Reverse (See Figure b) -

I. Idler Iever tension spring (b4) may be loose

or brokenl if so, the idler lever (68) will not be

actuated. Replace spring (54).

2. Check idler drive belt (6b), see Figure 6,

to see i{ it is properly connected.

No Drive on Record or Playback

@l. Idler tension spring (98 or gg) loose or

broken, thereby not holding idler wheel (?6) in en-

gagement with motor pulley (101) and flywheel (?l).

2. Idler slide plate (9?) binding on the slide

bushing (96), thus preventing the idler f rom moving

forward.

Tape Fails to Wind on Reel

D@-

l. Tape pressure pad not adjustedproperly,

resultingin the tape not beingheld against the record-

ing head. See 'rPressure Pad Adjustmentt'.

2. Becord head loose on its mounting. Adjust

head and tighten into position as described under

"Reeord-PIay Head Adjustment".

l. Reel drive spring (9) loose or broken. See

Figure 5.

Speed Variation or "Wow" (See Exploded View) -

l. Check capstan (6?), pinch roller (31), idler

(?6), m ot o r pulley (l0I), and flywheel (?l) for oil or

foreign material. Clean these parts with a good

cleaning fluid.

2. Check motor pulley (l0l) to see if it is

secured to motor.

3. Check idler tension spring (98 or g9); see

i-f it is holding the idler engaged with motor pulley

and flywheel.

4. Idler slide plate (9?) binding on the slide

bushing (96), preventing idler wheel (?6) from making

positive contact with motor pulley and flywheel.

Tape Overruns or Spills When Stop Button Is

D

I. Brake shoes out of adjustment. See "Brake

Shoe Adjustmenttt.

2. Brake pads worn out. Replace pads.

Failure to Record -

Fails to Erase -

I. Lock plate spring (49) Ioose or

resulting in the lock plate not being held

hinge bracket (46). See Figure 5.

Page 6

broken,

against the

I

3{

OF

En

gi)

6l

Page ?

tl )iffit $

Flgure ?"

ft"l 3i

dA,

trrtr

i ft3r

ffi1

fi3fi i

es,

'r@

*r5

'.@:

''.@)

,w

$

$

$

a

Sii} f;3t *34 ffi34iiftf fi

Page B

Figure 8.

3{

OF

E9

*6,

6l

z

o

zE

oii

Ia

H8

8g

o<

EM

o>

o4

Erl

trA

z2

zz

Fl EI

t1M

EiF

a {a-

U

tr

r{ :

q

I

sr

z-.

o:

F

Sd

bu

z4

OE

dO

<v)

o

z)

fr

vro

*)

iJs

<!

3o

F

o

I

c

bto

*O

=<

:\o

5e

o!

3<

eS

-6

=u.l

PO

=<

:€

=e

t\

x

6l

o

g

=

L

=

dJ

E

&

O

E

a).

=t

e

Page 9

i:;:il.i:r:r,:i:t ts lir tsE a \r::nri i

linsdrds!.+.:d!ril''(:liii.risie€iq{iqtilr6€Erei*r11**$iiMixlsqtess;

Figure 9.

3" Check the recording tape to see if the dull-

coated side faces inward on the reel. If the duII side

faces outward, a recording cannot be made. If this

condition exists, wind the tape onto an empty reel,

as described in "Threading the Tape".

CLEANING

The recordhead, capstan and pressure roller are

sub j e ct to an accumulation of tape coating residue,

which is worn off the tape as it passes these parts.

Use a soft cloth and alcohol to clean the head sur-

faces, capstan and pressure roller.

CAUTION: Do not use a brush when cleaning the

recording head as this could possibly mar

the laminations.

LUBRICATION

AII rotating parts are provided with generous - size

oilite bearings, which are f actory lubricated and

require no further attention.

An occasional cleaning out of foreign matte r under

the plastic pushbutton cover is desirable, and a

smaII drop of oil on the sliding Iever members is

advisable.

Neon Record Level Indicators-

The ne on record indicator firing level adjust-

mentisonly required if a neon bulb is replaced. The

twoneonrecordlevel indicators are adjusted for cor-

rectfiringlevel bymeans of two trimmer capacitors ,

one for each indicator.

To adjust indicators proceed as follows:

1. Turn Recordio on and depress Record push

button.

Page lC

2. Connect a short jumper lead across the bias

oscillator coil, Ll (short out the coil to disable

the oscillator).

3. Connect an audio oscillator, set at 1000

cycles, into the microphone input jack. Output

of audio oscillator should be approximatety .01

volts. (A 1 vott output level may be used with a

100 to 1 reductionpad of resistors inserted be-

tween the audio oscillator and the microphone

jack).

4. Connectprobe of lowcapacilytypeACVTVM

to junction of 2-330KQ resistors, R27 and R28 ,

(mounted on terminal strip near volume control) .

5. Adjustvolumecontrol to obtain a reading of

36 volts on VTVM and leave control set and

VTVM connected.

6. Disconnect shorting jumper from across bia.s

oscillator coil.

7 . Adjust Normal indicator trimmer(M6A) fully

clockwise and then turn slowly counterclockwise

so that upon loosening the trimmer the Normal

neon bulb barely lights. This adjustment must

be made loosening the trimmer.

8. Short out bias oscillator coil.

9. Increase volume control to obtain a reading

of 88 volts on the VTVM.

10. Remove short from bias oscillator coil.

11. Adjust Overload indicator trimmer (M6B) as

described in step "7", for just barely lighting

the Overload indicator bulb.

IMPORTANT: Do not readjust the recording bias os-

cillator adjustment a"fter setting the in-

dicator light adjustments.

_------

ELECTRICAL PARTS LIfIT

Ref .

No. Part

No. Description Ref .

No. Part

No. Descrtption

vr

v2

v3

v4

v5

clA

clB

clc

CID

c2A

c2B

c3

c4

c5

c6

c7

c8

c9

cI0

cu

cl2

c13

ct4

cr5

cr6

cr7

c18

cl9

c20

c2L

c22

c23

c24

c25A

c258

c26

c27

RI

R2

R3

R4

R5

M7A

M7B

c-5.42L-7

B-5.43?

D-3. r00-r8

c-4.109-13

c-4. 109-29

c-4.111-4

D-3. r00-?

c-4.109-2

D-3.100-18

B-4.115-1

c-4.109-2

c-4.109-2

c-4.109-13

c-4.109-9

D-3.100-18

c-4" 109-10

D-3.I00-7

c-4.109-10

c-4. 109-13

c-4.109-30

D-3.100-56

D-3.100-56

D-3.100-20

c-4.109-13

B-4.131

D-4.104-66

c-4.109-9

c-8.227-2

c-8.231-r

D-7.10r-loc

D-7.101-114

D-7.101-14t

B-U.230

I2AY7, AF AmP., Blas Osc.

l2A)(7, Mie Pre-Amp,,AF Amp.

6AQ5, Audio Output

6AQ5, Audio Output

5Y3, Rectifier

Electrolytic Cap., 20mfd.@ 450V.

Electrolytic Cap., 20mfd.@ 450V.

Electrolytic Cap.,20mfd.@ 450V.

Electrolytic Cap. ,20mfd.@ 25V.

Electrolytic Cap., 30mfd.@ 250V.

Electrolytic Cap., 30mld.@ 250V.

Cap. Paper Tub.,. 05nrfd.@ 200V.

Cap. Ceramic Tub., l500mmf .

Cap. Ceramic Tub. , IO0mrrf . +10%

Cap. Ceramic Tub., 2. 2mmf .

Cap. Paper Tub., .olmfd.@ 400V.

Cap. Ceramic Tub., 470mmf.

Cap. Paper Tub. r . 05rnfd.@ 200V.

Cap.Disc, .005mfd.

Cap. Ceramic Tub., 470 mmf .

Cap. Ceramlc Tub. , 470 mmf .

Cap. Ceramic Tub., 1500 mmf.

Cap. Ceramic Tub. , 1000 mml.

Cap. Paper Tub., . 05nfd.@200V.

Cap. Ceramic Tub., 100 mmf .

Cap. Paper Tub. , . olmfd.@ 400V.

Cap.CeramicTub., 100mmf.

Cap.Ceramic Tub., l500mnf.

Cap. Ceramic Tub., 4?mrrf . rI0%

Cap. Paper Tub., .035mfd.@40W

Cap. Paper Tub., . 035mf d.@ 4OOV

Cap. Paper Tub., .O5urfd.@ OOOV

Cap. Ceramic Tub., 1500mmf .

Cap.Disc, 4000mmf.

Cap.Dlsc, 4000mmf.

Cap. Mica, 470mmf . rl0%

Cap. Ceramic Tub. , I000mmf .

VolumeCont. & Switch, lMeg.,

Tapped

Tone Cont., 250K

Reslstor, l00KO, lrt W r+$%

Resistor, 220KQ, 12, W, +L0%

Resistor, 1. 5 Meg.,LhW. x.l}%

Play/Record Switch (Vtewed

from rear)

Play/Record Switch (Viewed

from front)

R6

R7

R8

R9

Rl0

Rll

R12

Rl3

R14

Rl5

R16

Rl7

Rt8

Rl9

R20

R21

R22

R23

R,24

R25

R26

R27

R28

R29

R30

R3l

R32

R33

R34

R35

T1

T2

sPl

LI

L2

Ml

M2

M3

M4

M5

M6.A

M6B

c-4. r34

e-4.134

c-4.I33

D-7.102-112

D-7.10r-58

D-?.101-r78

D-7.10r-178

D-7.r01-U4

D-7.10I-128

D-?.101-93

D-7.101-100

D-7.101-178

D-7.101-114

D-?. r01-86

D-7.101-155

D-7.10r-44

D-7.102-ll2

D-7.t02-72

D-7.103-153

D-7. r02-lr2

D-7.101-u4

D-7.10I-114

D-7.L02-22t

D-7.L02-72

D-7.101-121

D-?. r0r-121

D-7.101-128

c-6.215-r0

D-7.L02,217

D-7.r02-23

D-7. r03-58

D-7. r03-23

c-8.207-6

D-9.262

c-9.261

D-30.336

B-1.557

B-1.556

Reslstor, I20KO, llV, r I0$

Resistor, Ll'Ko, VZW, *L0%

Reslstor, 4. 7 Meg. rl/2 W, *,Ll%

Reslstor, 4. 7 Meg. ,l/2 Wrr,l}%

Resistor, 220NQ, l/2 W, *'l}%

Reststor, 470KO, L/2 W , *.L0%

Reslstor, 68KO, L/2 W, +10$

Reststor, l00KQ, L/2W, *L0%

Resistor, 4, 7 Meg. rvz W, x.L}%

Resistor, 220KO, V2 W, r\}ft

Reslstor, TKOTI/z W, rl0%

Resistor, 2. 2Meg., L/?W, *I}%

Resistor, 4. TKQ, Vz w, l'IO%

Reslstor, 120KQ, I W, *10%

Reslstor, 15KQ, 1W, xl}%

Reslstor, 39KO, 2 W, *105

Reslstor, l20KO, I W, dOft

Reslstor, 220KO, l/2W, rL}%

Resistor, 220KO, I/zW, r.L}%

Reststor, 2700, 1W, x.L9/s

Resistor, I5KO, l% t10%

Reslstor, 330KQ, L/2W, x.LO%

Reslstor, 330KQ, l/2 W, *IO%

Resistor, 4?0KO, L/2 W, *L0%

Reslstor, W.W., 3.3Q, ?W, d0$

Resistor, l0O, I W, + 20$

Reslstor, lKO, t W, r 10fr

Reslstor, 220Q, 2 W, * IOfr

Resistor, 33O, 2 W, * 10fr

Hum Balance Cont. 5 KO

Power Transformer

Output Transformer

SpeakerPM6xg

Bias Osc. Coil

Tone Choke

Pilot Lamp, Type #44

Neon Lamp, Type NEEI, Normal

Indicator

Neon Lamp, Type NE5I, Over-

load Indicator

Trlmmer, Bias Osc. Freq.

Adj. (3-35 mmf.)

Trimmer, Bias Adj. (3-35 mmJ.)

Trlmmer, Normal Indicator Adj.

(3-35 mmf.)

Trlmmer, Overload Indicator Adj

(3-35 mmf.)

3{

o=

H8

Fx

ee,

5l

MECHANICAL PARTS LIST

Ret

No. Part

No. Descliption IteI.

No. .gart

No. Description

I

2

3

4

5

6

I

I

I

10

II

t2

I3

l4

15

l6

1?

18

l9

c-13. 253

B-r3.261

D-r3.264

B-13.262

B-3r.330

c-13. 254

E -r3. 265

B-r9. 858

B-13. 258

c-13.254-2

E -I3" 266

B-32.282

35.775

B-3r. 338

Speed Shift Knob

Screw, 6-32 x 3/16 BHMS

#6 Cantlink Lockwasher

Reel Pan for Feed Reel

Rear Escutcheon

Screw, 6-32 x 3/16 BHMS

#6 Cantlink Lockwasher

Reel Pan for Take-Up Reel

ReeI Drive Spring (Belt)

Tone Control Knob

Front Escutcheon

Push Button Retainer Bracket

Push Button (Maroon), 5 Used

Screw, 6-32 x ?/16 RHIvI,S

Volume Control Knob

Base Plate

Tape Guide Post

Record Lock Lever Assembly

Record Lock Lever Return Spring

20

2t

22

23

24

25

26

27

28

29

30

31

32

33

34

35

B-32.276

B-3r.346

B-32.260

B-32"252

c-36. 156

c-36. 15?

B-33.409

B-28. 163

B-33.404

B-28. 163

35. ?6r

B-3r.336

B-19" 881

Hex Nut, 6-32

Tape Guide Post (Left)

Erase Head Adjustment Screw

Erase Head Forward Adjustment

Erase Head Retracting Spring

Tape Guide Post Spacer

Hex Nut, 6-32

Tape Guide (Right)

Recording Head, Shure #TRI6A

(Model 34'10)

Recording Head, Shure #TRl6

(Model 3AIl)

Hairpin CIip

Linen Washer

Pinch Roller

Linen Washer

Pinch Roller Plate Assembly

Pinch Roller Tension Spring

Playback Actuating Lever

Page 11

MECHANICAL PARTS LIST (Cont. )

Rei"

No. Part

No. Descriotion Ref .

No. Part

No. Description

36

37

38

39

40

4l

42

43

44

45

46

41

48

49

50

5l

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

?0

?1

12

?3

74

15

76

tt

?8

?9

80

81

82

B3

84

85

86

87

88

89

90

9l

92

93

94

95

96

97

35. ?58

B-r9.892

B-33.412

B-19.868

B-r9. B?2

B-31.34?

35. ?66

B-31. 334

B-3r.33?

B-19.859

B-19.8?0

B-3r.343

B-19. 8?7

B-31.338

c-r9.869

B-33.4r2

B-3r.339

35. ?59

35.114

B-31.333

35. ?5?

B-33.405

B-28.163

B-33.409

35. ?63

B-33.406

B-28. 162

B-19.840

B-32.259

35. ?6?

B-r9. 844

B-31.335

c-13. 25?

B-28. 163

c-r9.902

B-r9.863

B-33. 408

B-r9.862

c-19. 83?

D-36. I53

B-33.418

C-I9. BB?

33.4r5

B-28.159

B-33.409

B-28.163

B-I9.878

B-32.264

35. ?68

Playbaek Slide Plate Assembly

Pressure Pad Spring

Speed Nut, 3/f6 Stud

Record Slide Plate

Erase Head Plate

Erase Head Tension Spring

Record Actuating Lever Assembly

FeIt Pad

Screw (Spring Adjusting)

6-32 x 3/8 RHMS

Push Button Return Spring

Hinge Bracket for Push Buttons

Screw, 6-32 x I/4 Phillips Rd.

Hd. M. S.

Locking Plate for Push Buttons

Lock Plate Spring

Switch Lever (Amplifier)

Brake Return Spring

Brake Sli.de Plate

Speed Nut, 3/ 16 Stud

Idler Lever Tension Spring

Shift Plate for High Speed Assembly

Record Interlock Spring Assembly

Switch Arm Link

(Bottom View of Item 16)

Sub-IdIer Plate Assembly

Sub-Idler Wheel

Linen Washer

Ilairpin CIip

Speed Control Shaft Assembly

Idler Drive Sheave

Idler Drive BeIt

Idler Steady Bracket

Capstan Shaft

Idler Lever Assembly

Brake Arm

Brake Pad

Flywheel

Linen Washer

Brake Drum

Screw, 8-32 x L/ 48,H.

Drive Mounting Plate Bracket

2-L/ 2,' Rubber Bonded Idler

Angle Bracket

#8 Ext. Lockwasher

Screw, 8-32 x 3/8 R.H.

Motor Adaptor Plate

Washer (FIat), l/ 2 x 3/ 16 x L/ 32

Lockwasher, Internal #8

Screw (Sems), B-32 x 5/ 8

Motor

Truarc Retaining "E" Ring

Washer (Flat)

Felt Washer, 3/ 4 x l/ 4 x l/ 16

Fan Blade, 4"

Felt Washer, 3/ 4 x l/ 4 x L/ 16

Push-on: Fastener

Shock Mount

Hairpin Clip

Linen Washer

Speed Shift Lever

Screw, 6-32 x l/4 BHMS

Idler Slide Bushing

Idler Pulley Switch Slide Plate

Assembly

9B

99

100

101

r02

r03

t04

105

106

IO?

l0B

r09

ll0

tl1

112

113

1r4

115

116

u?

Ii8

ll9

t20

l2l

t22

r23

124

125

L26

r21

128

rzs

130

l3r

132

133

134

135

I36

I3?

138

139

140

l4l

r42

143

144

145

146

147

149

r50

l5l

152

153

154

r55

r56

157

I5B

159

160

B-3r.324

B-31.324

B-31.327

B-32.262

B-r9.8?9

35. ?56

35. ?55

B-28.163

B-28.163

B-r9.883

B-33.400

B-32. 26I

B-33.3?0

B-23. 163

B-33.409

B-28. 163

B -33. 40?

B-r9.916

B-28. 163

B-32. 261

35. ?53

I

ldler Tension Spring

ldler Tension Spring

tdler Lift Compression Spring

Motor Pu1ley

Jcrew

Lockwasher, Internal #8

Washer (Flat), L/ 2 x 3/16 xl/ 32

ldler Throw Out Lever

3-32 x l" O. C. Phil. Hd.

Felt Washer 3/ 4 x L/ a x I/ 16

FeIt Washer 3/ 4 x L/ 4 x I/ 16

3-32 x l/ 2 PhlL. IId. O. C. M. S.

3-32 x l/4 Hex Nut

F6 Int. Lockwasher

3/ 8 x l/ B x l/ 32 Flat Washer

3/ 8 x I/ B x l/ 32 Flat Washer

#6 Int. Lockwasher

3-32 x l/4 Hex Nut

Felt Washer 3/ a x | 4 x l/ 16

3-32 x r/ 2 Phlr. Hd. o. C. M" S.

2 x 56 x 3/16 Hex Nut

#2 Int. Lockwasher

Perm. Magnet Assembly

Push Button Lever Assembly

Linen Washer

Linen Washer

Washer

Rivet,.122 x 5/ 32

8-32 x Il/32 Hex Nut

Bracket (Input Jack)

Midget Jack

Shoulder Washer

FIat Washer l/ 2 x 3/ 16 x l/ 32

#8 Ext. Lockwasher

8-32 x 5/16 BHMS

6-32 x l/2 Blil\4s

#6 Int. Lockwasher

Rivet, .122 x 5/ 32

Phono Jack

B-32 x 1/ 4 Undercut Flat Hd.

Linen Washer

B-32 x 3/16 Allen Hd. Set Screw

Hairpin CIip

Linen Washer

#8 Ext. Lockwasher

l/ 2 x[/ 6a xl32 Flat Washer

B-32 x 3/8 RHMS

#8 Ext. Lockwasher

B-32 x I/4 BHMS

#B Ext. Lockwasher

#8 Ext. Lockwasher

8-32 x i/4 BIIMS

8-32x3/BBHMS

#B Ext. Lockwasher

L/ 2 x 3/ L6 x 3/ 64 Flat Washer

ttCt'Washer

#4 x 3/16 P. K. Screw Hex Hd.

Spring CIip

Linen Washer

Shor.rlder Washer

8-32 x lrl4 Alten Hd. Set Screw

Motor & Transf. Mtg. Assembly

Page 12

Table of contents

Other Wilcox-Gay Voice Recorder manuals