Wilder Technologies QSFP-DD User manual

QSFP-DD Test Adapter User Manual

Page | 1

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

QSFP-DD

Test Adapter

User Manual

QSFP-DD Test Adapter User Manual

Page | 2

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Table of Contents

Introduction...........................................................................................................................3

Product Inspection..................................................................................................................5

The QSFP-DD Test Adapter Care and Handling Precautions .......................................................6

General Test Adapter, Cable, and Connector............................................................................8

Handling and Storage..........................................................................................................8

Visual Inspection.................................................................................................................8

Cleaning.............................................................................................................................8

Making Connections ...........................................................................................................8

Electrostatic Discharge Information.........................................................................................9

User Model..........................................................................................................................10

Calibration Through De-Embedding.......................................................................................13

Mechanical and Environmental Specifications........................................................................14

Electrical Specifications.........................................................................................................29

QSFP-DD Mated HCBs/MCB Performance Plots......................................................................30

QSFP-DD MCB (Receptacle) Test Adapter Reference Information ............................................60

Wilder Technologies, LLC – Limited Warranty.........................................................................61

Wilder Technologies, LLC – Terms & Conditions of Sale...........................................................62

Compliance with Environmental Legislation ...........................................................................63

WEEE Compliance Statement ............................................................................................63

Compliance To RoHS 2 Substance Restrictions....................................................................63

Glossary of Terms.................................................................................................................64

Index ...................................................................................................................................65

QSFP-DD Test Adapter User Manual

Page | 3

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Introduction

This user’s guide documents the QSFP-DD Legacy Plug, QSFP-DD Plug, QSFP-DD RX Plug,

QSFP-DD TX Plug and QSFP-DD Receptacle Test Adapters.

Model Numbers (QSFPDD-TPAK-HCB-LGCY-P, QSFPDD-TPAK-HCB-DD-P, QSFPDD-TPAK-HCB-RX-P,

QSFPDD-TPAK-HCB-TX-P and QSFPDD-TPAHK-MCB-R). The two test adapter types, shown in

Figures 1 and 2, test QSFP-DD interface cables, hosts, and modules to the requirements of the

QSFP-DD MSA and IEEE 802.3cd Standards.

The QSFP-DD HCB (Plug) and QSFP-DD MCB (Receptacle) test adapter assemblies allow easy

access, via 2.92mm (K-Style) connections, to measure or inject data signals.

NOTE: To avoid damaging the cables, use the handling techniques

described in the Care and Handling section before making any

connections or configuring a test setup.

Always use a static-safe workstation when performing tests, as

explained in the “Electrostatic Discharge Information” section.

Figure 1. The QSFP-DD HCB (Plug) Test Adapter (Note: The coaxial cables are configuration dependent

and may be terminated with different connectors and have different color-coding than what is shown.)

QSFP-DD Plug

Connector

Assembly

16 (K-Style) 2.92mm

Connectors (Female

Shown) forHigh-

Speed Testing

Low-Speed

Connector, P2

QSFP-DD Test Adapter User Manual

Page | 4

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Figure 2. The QSFP-DD MCB (Receptacle)Test Adapter (Note: The coaxial cables areconfiguration

dependent and may be terminated with different connectors than what is shown.)

NOTE: The metal shell of both the plug (QSFP-DD HCB) and

receptacle (QSFP-DD MCB) connectors tie high-speed ground to

chassis ground.

The low-speed 12-position receptacle and plug connectors are keyed and latching (Molex

part number 43645-1200 for the plug TPA and 43650-1204 for the receptacle TPA). The mating

connector housings and contact pins for 26-30awg wire are Molex part number 43640-1201 for

the 12-position housing and 43031-0011 for the plug contacts used with the plug TPA, and

Molex part number 43645-1200 for the 12-position housing and 43030-0011 for the receptacle

contacts used with the receptacle TPA. Replacement parts can be purchased through Molex

distributors.

NOTE: The receiver 2.92mm (K-Style) connections for QSFP-DD are

normally AC coupled. The QSFP-DD plug and receptacle TPAs do NOT

have internal DC Blocks. This allows for parametric testing through

the TPAs. Normal testing may require DC Blocks (May be optionally

ordered from Wilder Technologies). Refer to the Electrical

Specifications section of this document for DC Block performance

parameters.

32 (K-Style)

2.92mm

Connectors

(Female Shown)

for High-Speed

Low-Speed Connector

(Side, Not Shown)

QSFP-DD

Receptacle

QSFP-DD Test Adapter User Manual

Page | 5

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Product Inspection

Upon receiving QSFP-DD Test Adapters from Wilder Technologies, perform the following

product inspection:

•Inspect the outer shipping container, foam-lined instrument case, and product for damage.

Retain the outer cardboard shipping container until the contents of the shipment have been

inspected for completeness and the product has been checked mechanically and electrically. Use

the foam-lined instrument-case for secure storage of the Wilder Technologies QSFP-DD Test

Adapter when not in use.

•Locate the shipping list and verify that all items ordered were received.

•In the unlikely event that the product is defective or incomplete, the “Limited Warranty” section

discusses how to contact Wilder Technologies for technical assistance and/or how to package the

product for return.

QSFP-DD Test Adapter User Manual

Page | 6

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

The QSFP-DD Test Adapter Care and Handling Precautions

The QSFP-DD Test Adapters requires careful handling to avoid damage. Improper handling

techniques, or using too small a cable bend radius, can damage the coaxial cable connections

within the adapter housing or the cables themselves. This can occur at any point along the

cable. To achieve optimum performance and to prolong the QSFP-DD TPA’s life, observe the

following handling precautions:

•CAUTION 1: Avoid Torque Forces (Twisting)

While individual coaxial cables within the test adapter have some rotational freedom,

twisting the QSFP-DD TPA as a unit, with one end held stationary, may damage or severely

degrade performance. Adherence to Caution 5 (below) helps to avoid twisting.

•CAUTION 2: Avoid Sharp Cable Bends

Never bend coaxial cables into a radius of 26 mm (1-inch) or less. Never bend cables

greater than 90°. Single or multiple cable bends must be kept within this limit. Bending the

QSFP-DD TPA cables less than a 26mm (1-Inch) radius will permanently damage or severely

degrade test adapter performance.

•CAUTION 3: Avoid Cable Tension (Pull Forces)

Never apply tension (pull forces) to an individual coaxial cable that is greater than 2.3 kg

(5 lbs.). To avoid applying tension, always place accessories and equipment on a surface

that allows adjustment to eliminate tension on the QSFP-DD TPA and cables. Use adjustable

elevation stands or apparatus to accurately place and support the QSFP-DD TPA.

•CAUTION 4: Connect the QSFP-DD Test Adapter First

To prevent twisting, bending, or applying tension to the coaxial cables when connecting a

QSFP-DD TPA, always attach the QSFP-DD TPA to the device under test (DUT) or cable under

test before attaching any 2.92mm (K-Style) connectors. Carefully align the QSFP-DD

connectors and then gently push the connectors together until fully seated.

If the QSFP-DD TPA must be turned or twisted to make connection to the DUT, avoid using

the QSFP-DD TPA housing alone to make this occur.Try to distribute the torque forces along

the length of the test setup and cabling. If this is not possible, it is recommended to first

loosen or disconnect the 2.92mm (K-Style) connections at the QSFP-DD TPA, make the

connection to the DUT and then re-tighten or attach the test equipment leads.

NOTE: Only grip the test adapter housing when inserting or

extracting the QSFP-DD TPA to or from the DUT. Pulling directly on

the QSFP-DD TPA cables or using them to insert the QSFP-DD TPA

may cause damage.

•CAUTION 5: Carefully Make High-Speed (2.92mm, K-Style) Connections

To connect the QSFP-DD TPA 2.92mm (K-Style) connectors, follow these steps:

1. Hold the cable stationary by grasping the cable at the black heat-shrink section

near the High-Speed connector.

2. Insert the mating High-Speed connector barrel and hand-tighten the free-spinning

2.92mm connector (K-Style) nut onto the connector while avoiding pulling,

bending, or twisting the QSFP-DD TPA coaxial cable.

QSFP-DD Test Adapter User Manual

Page | 7

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

3. The QSFP-DD TPA 2.92mm connectors (K-Style) have flats that accept an open-end

1/4-inch or 5/16-inch wrench, depending on configuration. When attaching

instrument cables to the QSFP-DD TPA, it is recommended that the QSFP-DD TPA

high-speed connectors be mechanically held and the test leads be tightened to the

equipment manufacturer’s torque recommendations, normally 5 in-lbs., using an

open-end torque wrench.

If the test set-up requires repositioning, first loosen or disconnect the 2.92mm (K-Style)

connections to avoid twisting, bending, or tension.

NOTE: A drop in signal amplitude by half or 6dB during the testing of

a channel may indicate that a cable has been mechanically pulled

free of coaxial cable connections internal to the assembly. This could

be determined by checking if the cable has any lateral play relative

to the TPA. This would only occur when the TPA has exceeded the

pull force as specified within the mechanical specification. If the

cable cannot be re-seated, the test adapter will need to be sent back

to the factory for service.

•CAUTION 6: Independently Support Instrument Cables or Accessories

Excessive weight from instrument cables and/or accessories connected to the QSFP-DD TPA

can cause damage or affect the test adapter performance. Be sure to provide appropriate

means to support and stabilize all test set-up components.

•CAUTION 7: ESD Sensitivity

The QSFP-DD test adapters are passive components and are not in themselves sensitive to

electrostatic discharge. However, when an active DUT is installed, that device becomes

susceptible to ESD. Observe proper ESD precautions, further discussed later in this

document.

QSFP-DD Test Adapter User Manual

Page | 8

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

General Test Adapter, Cable, and Connector

Observing simple precautions can ensure accurate and reliable measurements.

Handling and Storage

Before each use of the QSFP-DD TPA, ensure that all connectors are clean. Handle all cables

carefully and store the QSFP-DD TPA in the foam-lined instrument case when not in use, if

possible. Do not set connectors contact end down. Install the high-speed connector protective

end caps when the QSFP-DD TPA is not in use.

Visual Inspection

Be sure to inspect all cables carefully before making a connection. Inspect all cables for

metal particles, scratches, deformed threads, dents, or bent, broken, or misaligned center

conductors. Do not use damaged cables.

Cleaning

If necessary, clean the connectors using low-pressure (less than 60 PSI) compressed air or

nitrogen with an effective oil-vapor filter and condensation trap. Clean the cable threads, if

necessary, using a lint-free swab or cleaning cloth moistened with isopropyl alcohol. Always

completely dry a connector before use. Do not use abrasives to clean the connectors.Re-

inspect connectors, making sure no particles or residue remains.

Making Connections

Before making any connections, review the “Care and Handling Precautions”section. Follow

these guidelines when making connections:

•Align cables carefully

•Make preliminary connection lightly

•To tighten, turn connector nut only

•Do not apply bending force to cable

•Do not over-tighten preliminary connections

•Do not twist or screw-in cables

•Use an appropriately sized torque wrench, and do not tighten past the “break” point of the

torque wrench (normally 5 inch pounds)

QSFP-DD Test Adapter User Manual

Page | 9

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Electrostatic Discharge Information

Protection against electrostatic discharge (ESD) is essential while connecting, inspecting, or

cleaning the QSFP-DD TPA test adapter and connectors attached to a static-sensitive circuit

(such as those found in test sets).

Electrostatic discharge can damage or destroy electronic components. Be sure to perform all

work on electronic assemblies at a static-safe work station, using two types of ESD protection:

•Conductive table-mat and wrist-strap combination

•Conductive floor-mat and heel-strap combination

When used together, both types provide a significant level of ESD protection. Used alone, the

table-mat and wrist-strap combination provide adequate ESD protection. To ensure user safety,

the static-safe accessories must provide at least 1 MΩ of isolation from ground. Acceptable ESD

accessories may be purchased from a local supplier.

WARNING: These techniques for a static-safe work station should

not be used when working on circuitry with a voltage potential

greater than 500 volts.

QSFP-DD Test Adapter User Manual

Page | 10

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

User Model

The QSFP-DD TPAs are capable of performing to the requirements of both IEEE and SFF

specifications, limited only by the specifications, environmental, care and handling of this

document.

In the case where the laboratory source or load is not used in the test, it must be replaced

with RF terminations on each unused signal. (NOTE: DC Blocks and RF terminators are

optionally offered by Wilder Technologies.)

The following examples are suggestions for possible testing setups.

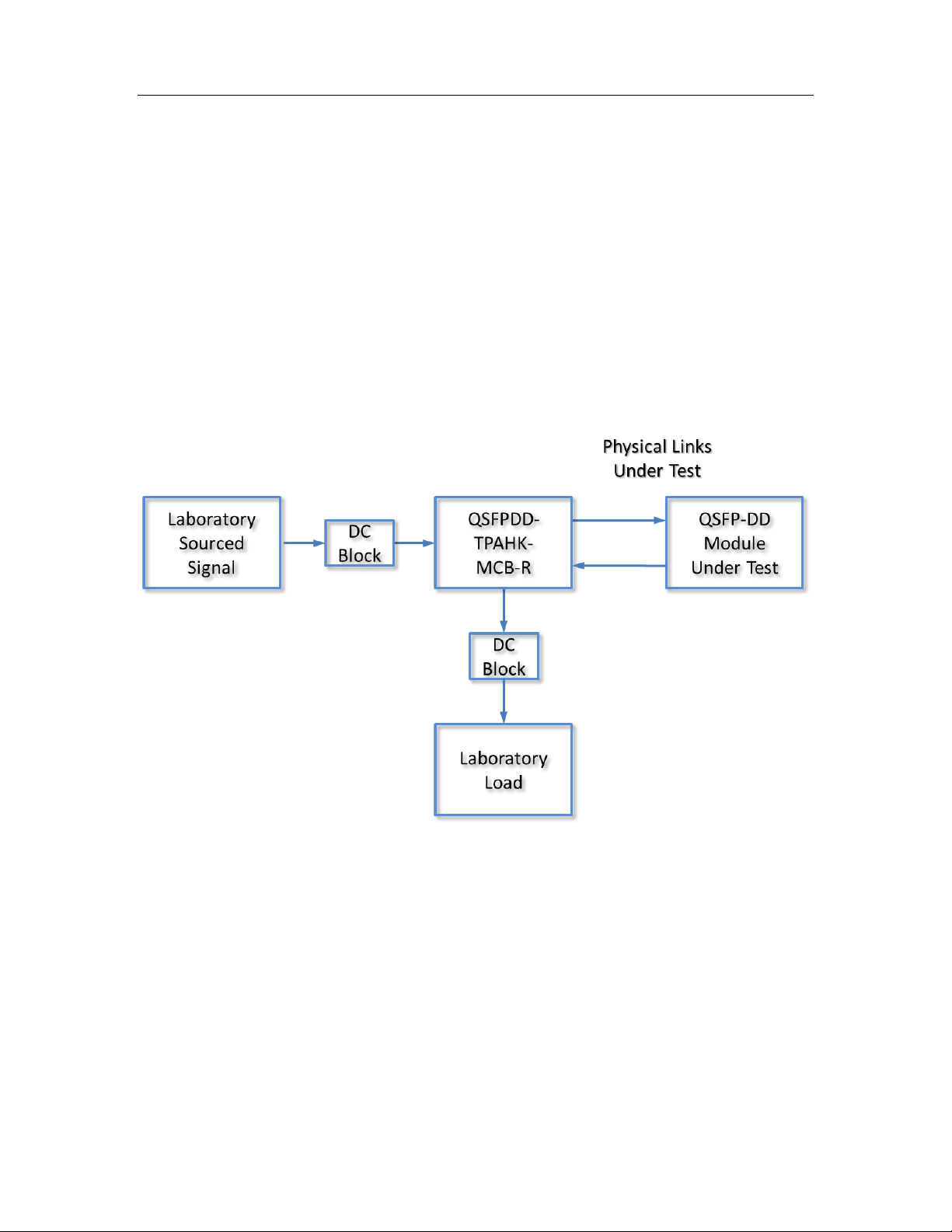

In this first example, a QSFPDD TPAHK-MCB-R is used to test a QSFP-DD Module:

QSFP-DD Test Adapter User Manual

Page | 11

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

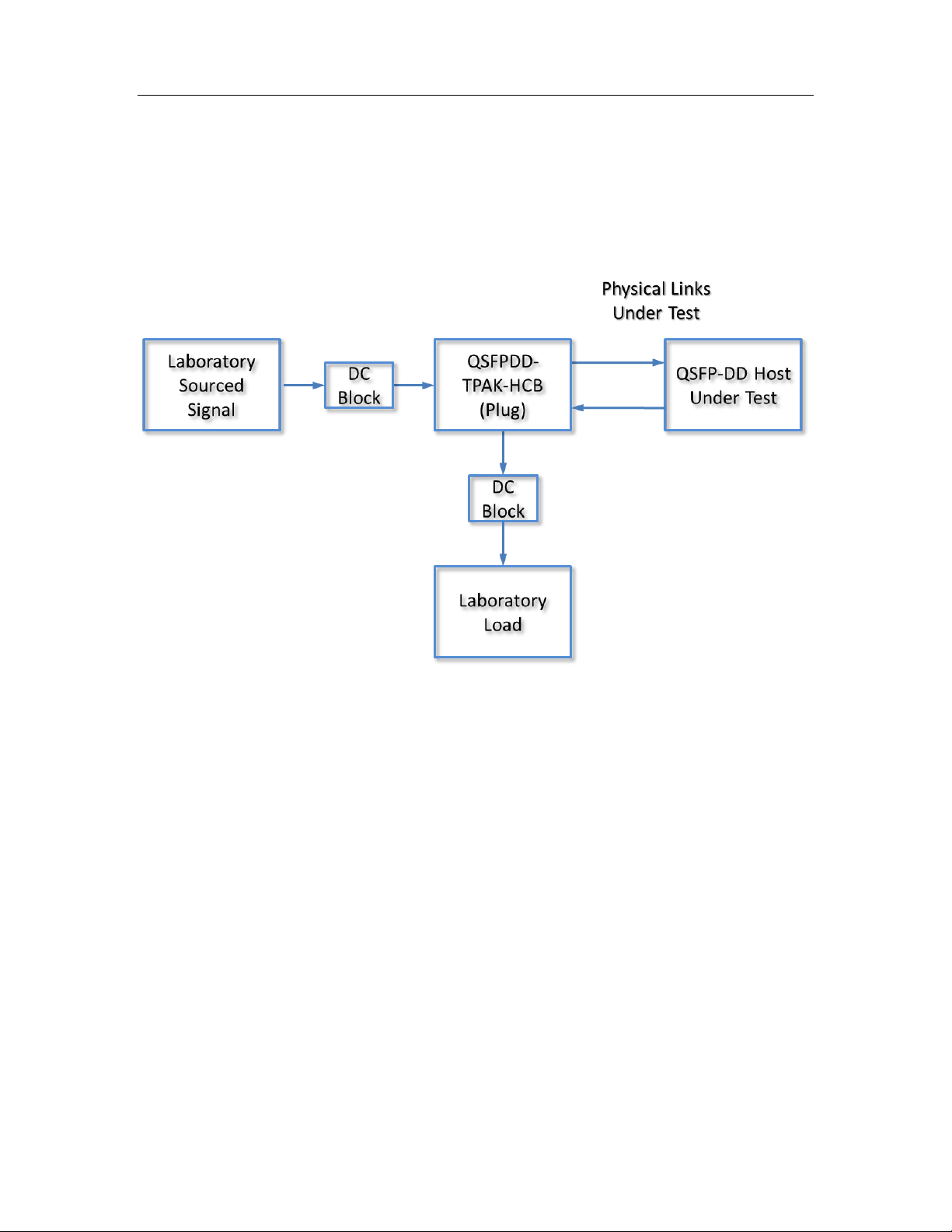

The second example shows a QSFPDD-TPAK-HCB (Plug) is used to test a host:

In the case where the laboratory source or load is not used in the test, it must be replaced

with RF terminations on each unused signal. (NOTE: DC Blocks and RF terminators are

optionally offered by Wilder Technologies.)

QSFP-DD Test Adapter User Manual

Page | 12

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

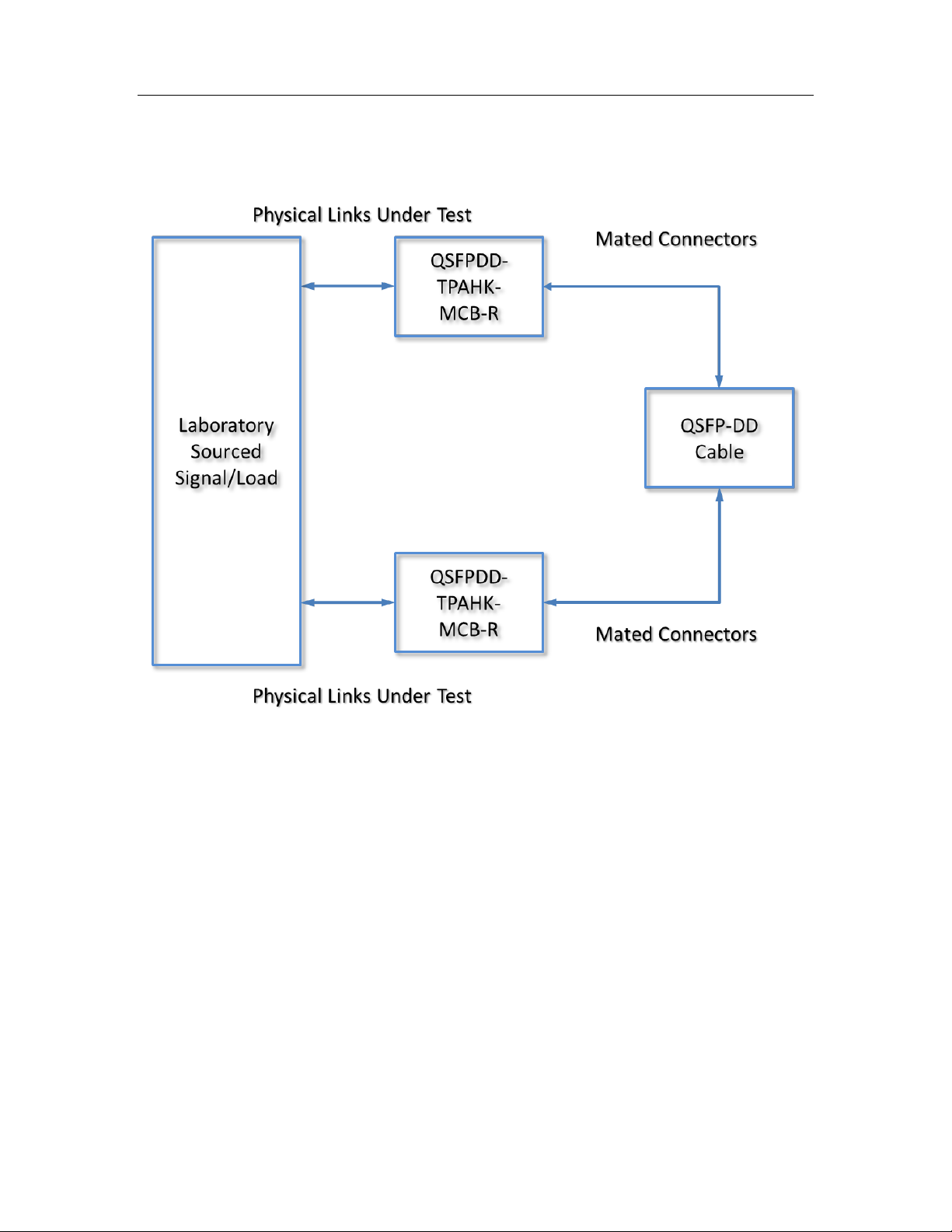

The third example shows two QSFPDD-TPAHK-MCB-R’s used for testing a QSFP-DD cable:

QSFP-DD Test Adapter User Manual

Page | 13

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Calibration Through De-Embedding

The QSFP-DD Test Adapters are fully passive components. Therefore, calibration

compensating for the losses must occur within the test instrumentation that drives the QSFP-

DD Receivers or looks at the response of the QSFP-DD Transmitters.

The QSFP-DD TPA’s have Touchstone S4P files for de-embedding the electrical length and

losses within the TPA up to the QSFP-DD connector interface pads. (Contact Wilder

Technologies, support@wilder-tech.com,to obtain a copy of the S4P files.) The Touchstone S4P

files enable the test engineer to compensate for the last four of the following six repeatable,

systematic errors that occur when moving the reference plane:

•Signal leakage effects: Directivity errors

•Signal leakage effects: Crosstalk errors

•Reflection effects: Source Impedance Mismatching errors

•Reflection effects: Load Impedance Mismatching errors

•Bandwidth effects: Receiver Transmission in Test Equipment errors

•Bandwidth effects: Receiver Reflection-tracking in Test Equipment errors

These errorsare corrected on each port. Refer to the Instrument Manual for instructions on

the instrument’s specific de-embedding process.

NOTE: The reference plane is the boundary, both physically and

electrically, between the calibrated and uncalibrated portions of

the circuit. Everything outside the reference plane is considered

part of the DUT. Any instrument that does not use calibration or de-

embedding of the test fixture defines the DUT as the total of

externally connected components. If the de-embedding file is not

used, all of the QSFP-DD TPA and associated coaxial cables, as well as

cables connecting the TPA assembly to the test instrument, would be

a part of the DUT.

Non-repeatable errors, such as drift or random errors, can be reduced but not corrected.

Drift errorsaggregate over time or with environmental changes such as temperature shift. To

eliminate drift errors,perform an instrumentation-level calibration.

A random error cannot be corrected through calibration since the error occurred randomly.

Random errors are typically associated with either test instrument noise or test repeatability

problems. Reduce test instrument noise by increasing source power, lowering the IF

bandwidth, or averaging results over multiple sweeps. Reduce test repeatability problems

through the use of a torque wrench or, again, by averaging over multiple sweeps.

QSFP-DD Test Adapter User Manual

Page | 14

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Mechanical and Environmental Specifications

NOTE: All specifications in this manual are subject to change.

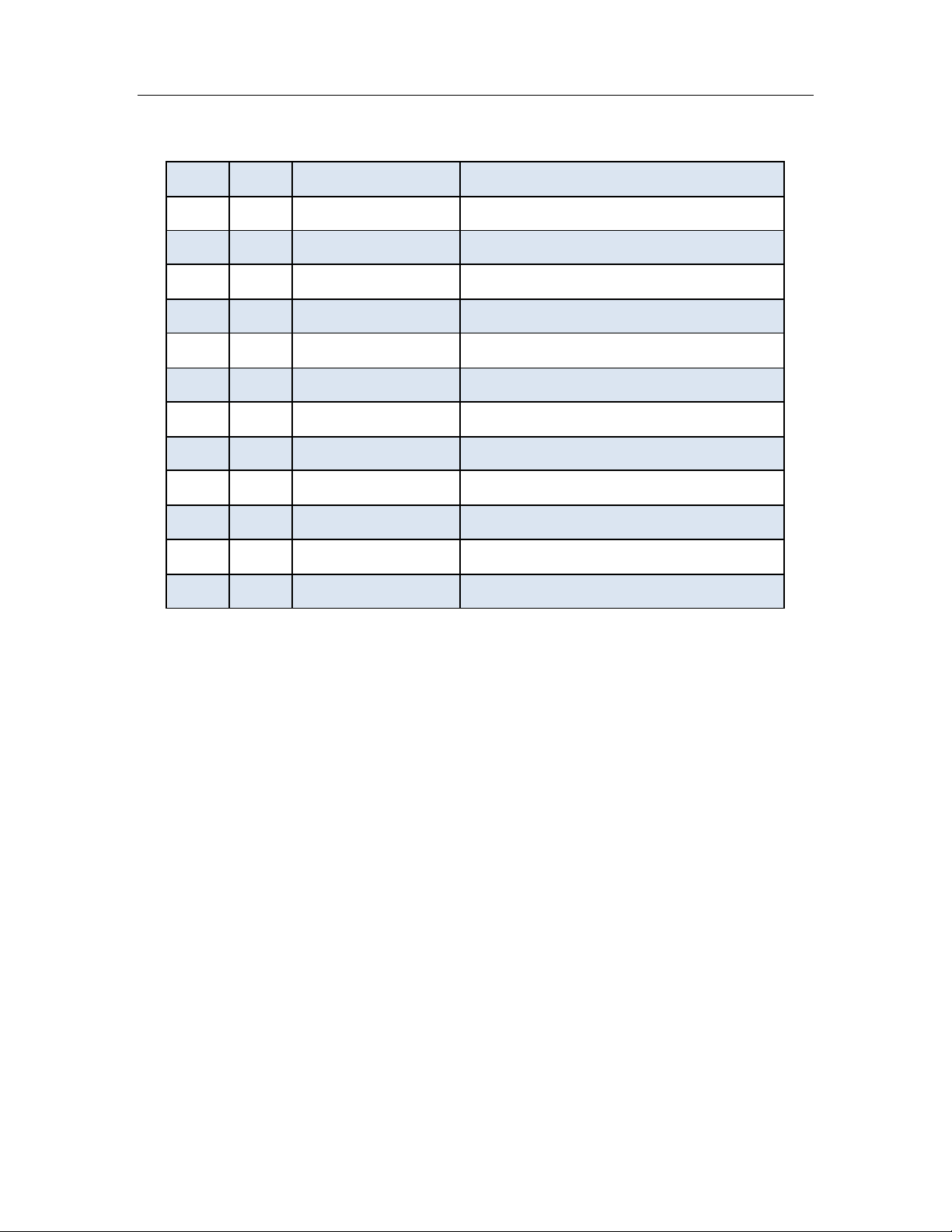

Table 1. General Specifications

ITEM DESCRIPTION

Usage Environment Controlled indoor environment

Plug Test Adapter Length (w/standard cables)

263.00 mm +/- 2 mm (10.35 inches +/- .08 inches)

(Characteristic)

Receptacle Test Adapter Length (w/standard

cables, end to end)

236.22 mm +/- 2 mm (9.30 inches +/- .08 inches)

(Characteristic)

Receptacle Test Adapter Housing Dimensions 125.98 x 106.43 x 74.68 (4.96 x 4.19 x 2.94 inches) (L, W, H)

Operating Temperature 0°C to +55°C (32°F to +131°F) (Characteristic)

Storage Temperature -40°C to +70°C (-40°F to +158°F) (Characteristic)

QSFPDD-TPAK-HCB (Plug)

Each of the four configurations of Plug-Type QSFPDD-TPAK-HCB test adapters (Legacy, DD, Rx

and Tx) provide sixteen 2.92mm (K-Style) connectors (four lanes of primary differential signals).

Labels clearly mark each cable or connector. The following figure refers to the pin-description

tables for the QSFPDD-TPAK-HCB (Plug) test adapters.

Figure 3. Cable Connectors (QSFPDD-TPAK-HCB shown). (Note: The coaxial cables areconfiguration

dependent and may be terminated with different connectors and have different color-coding than what

is shown.)

Low-Speed Connector, P2

(See Table 2)

QSFP-DD Plug Connector

(See Table 3 forLegacy)

(See Table 4 for DD)

(See Table 5 forRx)

(See Table 6 forTx)

16 (K-Style) 2.92mm

Connectors (Female

Shown) forHigh-

Speed Testing

Color-Coded and Imprinted Markings

(Large Colored = ChannelNumber)

(Short White = Transmit Side)

(Short Red = Positive Polarity)

See Tables 3 (Legacy), 4 (DD), 5 (Rx), 6 (Tx)

QSFP-DD Test Adapter User Manual

Page | 15

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Table 2. QSFPDD-TPAK-HCB (Plug) 12-Position Cable Connector(Low-Speed).

(NOTE: Connections are common to Legacy, DD, Rx and Tx configurations)

LABEL PIN NO. COLOR ID FOR HCB DESCRIPTION

GND Pin 1 Black Signal (RF Ground) and Supply (Power) Common

MPL Pin 2 Black Module Present

ITL Pin 3 Black Interrupt

SDA Pin 4 Black SDA, I2C Data for DDC

SCL Pin 5 Black SCL, I2C Clock for DDC

RSL Pin 6 Black Module Reset

MSL Pin 7 Black Module Select

LPM Pin 8 Black Low Power Mode

VCC Pin 9 Not Present/Connected Vcc1 module power supply (+3.3V)

VCR Pin 10 Not Present/Connected VccR, module receiver power supply (+3.3V)

VCT Pin 11 Not Present/Connected VccT, module transmitter power supply (+3.3V)

GND Pin 12 Black Signal (RF Ground) and Supply (Power) Common

QSFP-DD Test Adapter User Manual

Page | 16

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Table 3. QSFPDD-TPAK-HCB-LGCY-P (Legacy Plug) Pin Assignments

Pin Description Connector

Pin Number

Destination (HCB) Color ID for Data

Line Polarity

Color Identification

(HCB)

Ground 1

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx2n 2 Tx2- Black White/Blue

Tx2p 3 Tx2+ Red White/Blue

Ground 4

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx4n 5 Tx4- Black White/Red

Tx4p 6 Tx4+ Red White/Red

Ground 7

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

MSL 8 P2 Pin 7 N/A Black Insulation

RSL 9 P2 Pin 6 N/A Black Insulation

VccR 10

Not

Present/Connected

N/A

Not

Present/Connected

N/A

SCL 11 P2 Pin 5 N/A Black Insulation

SDA 12 P2 Pin 4 N/A Black Insulation

Ground 13

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx3p 14 Rx3+ Red Green

Rx3n 15 Rx3- Black Green

Ground 16

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx1p 17 Rx1+ Red Yellow

Rx1n 18 Rx1- Black Yellow

Ground 19

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Ground 20

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx2n 21 Rx2- Black Blue

Rx2p 22 Rx2+ Red Blue

Ground 23

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx4n 24 Rx4- Black Red

Rx4p 25 Rx4+ Red Red

Ground 26

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

MPL 27 P2 Pin 2 N/A Black Insulation

QSFP-DD Test Adapter User Manual

Page | 17

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

ITL 28 P2 Pin 3 N/A Black Insulation

VccT 29

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Vcc1 30

Not

Present/Connected

N/A

Not

Present/Connected

N/A

LPM 31 P2 Pin 8 N/A Black Insulation

Ground 32

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx3p 33 Tx3+ Red White/Green

Tx3n 34 Tx3- Black White/Green

Ground 35

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx1p 36 Tx1+ Red White/Yel low

Tx1n 37 Tx1- Black White/Yellow

Ground 38

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

QSFP-DD Test Adapter User Manual

Page | 18

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Table 4. QSFPDD-TPAK-HCB-DD-P (DD Plug) Pin Assignments

Pin Description Connector

Pin Number

Destination (HCB) Color ID for Data

Line Polarity

Color Identification

(HCB)

MSL 8 P2 Pin 7 N/A Black Insulation

RSL 9 P2 Pin 6 N/A Black Insulation

VccR 10

Not

Present/Connected

N/A

Not

Present/Connected

N/A

SCL 11 P2 Pin 5 N/A Black Insulation

SDA 12 P2 Pin 4 N/A Black Insulation

MPL 27 P2 Pin 2 N/A Black Insulation

ITL 28 P2 Pin 3 N/A Black Insulation

VccT 29

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Vcc1 30

Not

Present/Connected

N/A

Not

Present/Connected

N/A

LPM 31 P2 Pin 8 N/A Black Insulation

Ground 39

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx6n 40 Tx6- Black White/Br own

Tx6p 41 Tx6+ Red White/Brown

Ground 42

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx8n 43 Tx8- Black White/White

Tx8p 44 Tx8+ Red White/White

Ground 45

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Reserved 46

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VS1 47

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VccRx1 48

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VS2 49

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VS3 50

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Ground 51

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx7p 52 Rx7+ Red Violet

Rx7n 53 Rx7- Black Violet

Ground 54

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

QSFP-DD Test Adapter User Manual

Page | 19

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Rx5p 55 Rx5+ Red Orange

Rx5n 56 Rx5- Black Orange

Ground 57

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Ground 58

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx6n 59 Rx6- Black Brown

Rx6p 60 Rx6+ Red Brown

Ground 61

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx8n 62 Rx8- Black White

Rx8p 63 Rx8+ Red White

Ground 64

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

NC 65

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Reserved 66

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VccTx1 67

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Vcc2 68

Not

Present/Connected

N/A

Not

Present/Connected

N/A

ePPS 69

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Ground 70

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx7p 71 Tx7+ Red White/Violet

Tx7n 72 Tx7- Black White/Vi olet

Ground 73

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Tx5p 74 Tx5+ Red White/Orange

Tx5n 75 Tx5- Black White/Orange

Ground 76

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

QSFP-DD Test Adapter User Manual

Page | 20

©2019 Wilder Technologies, LLC

DocumentNo. 910 -0057-000Rev. A

Table 5. QSFPDD-TPAK-HCB-RX-P (Rx Plug) Pin Assignments

Pin Description Connector

Pin Number

Destination (HCB) Color ID for Data

Line Polarity

Color Identification

(HCB)

MSL 8 P2 Pin 7 N/A Black Insulation

RSL 9 P2 Pin 6 N/A Black Insulation

VccR 10

Not

Present/Connected

N/A

Not

Present/Connected

N/A

SCL 11 P2 Pin 5 N/A Black Insulation

SDA 12 P2 Pin 4 N/A Black Insulation

Ground 13

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx3p 14 Rx3+ Red Green

Rx3n 15 Rx3- Black Green

Ground 16

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx1p 17 Rx1+ Red Yellow

Rx1n 18 Rx1- Black Yellow

Ground 19

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Ground 20

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx2n 21 Rx2- Black Blue

Rx2p 22 Rx2+ Red Blue

Ground 23

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

Rx4n 24 Rx4- Black Red

Rx4p 25 Rx4+ Red Red

Ground 26

Coax Shield and

P2 Pin 1, 12

N/A Black Insulation

MPL 27 P2 Pin 2 N/A Black Insulation

ITL 28 P2 Pin 3 N/A Black Insulation

VccT 29

Not

Present/Connected

N/A

Not

Present/Connected

N/A

Vcc1 30

Not

Present/Connected

N/A

Not

Present/Connected

N/A

LPM 31 P2 Pin 8 N/A Black Insulation

Reserved 46

Not

Present/Connected

N/A

Not

Present/Connected

N/A

VS1 47

Not

Present/Connected

N/A

Not

Present/Connected

N/A

This manual suits for next models

5

Table of contents

Other Wilder Technologies Adapter manuals