Wilder Technologies SATA 2.5 Test Adapter User manual

SATA2.5TestAdapterUserManual

Page|1

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

SATA2.5

TestAdapter

UserManual

SATA2.5TestAdapterUserManual

Page|2

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

TableofContents

Introduction.....................................................................................................................................3

ProductInspection..........................................................................................................................5

TheSATA2.5TestAdapterCareandHandlingPrecautions...........................................................6

GeneralTestAdapter,Cable,andConnector..................................................................................8

HandlingandStorage..................................................................................................................8

VisualInspection..........................................................................................................................8

Cleaning.......................................................................................................................................8

MakingConnections....................................................................................................................8

ElectrostaticDischargeInformation................................................................................................9

UserModel....................................................................................................................................10

Calibration.....................................................................................................................................15

SOLT...........................................................................................................................................16

1X‐THRU....................................................................................................................................17

MechanicalandEnvironmentalSpecifications..............................................................................18

ElectricalSpecifications.................................................................................................................22

WilderTechnologies,LLC–LimitedWarranty..............................................................................33

WilderTechnologies,LLC–Terms&ConditionsofSale...............................................................34

CompliancewithEnvironmentalLegislation.................................................................................35

WEEEComplianceStatement....................................................................................................35

GlossaryofTerms..........................................................................................................................36

Index..............................................................................................................................................37

SATA2.5TestAdapterUserManual

Page|3

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

Introduction

Thisuser’sguidedocumentstheSATA2.5PlugandReceptacleTestAdapters(SATA2.5‐TPA‐P

andSATA2.5‐TPA‐R)andtheassociatedCalibrationCables.Thetwotestadaptertypes,shown

inFigures1and2,testSATAinterfacecables,hostsanddevicesagainsttheSATASpecification

2.5.TheCalibrationCables,presentedonPage15,areusedtozero‐outtestadapterattributes

(usingSOLT,witheitherthe1X‐THRUorthe2X‐THRU).

TheTPA‐PandTPA‐Rtestadapterassembliesalloweasyaccess,viaSMAconnections,to

measureorinjectDatasignals.

NOTE:Toavoiddamagingthecables,usethehandlingtechniques

describedintheCareandHandlingsectionbeforemakingany

connectionsorconfiguringatestsetup.

Alwaysuseastatic‐safeworkstationwhenperformingtests,as

explainedinthe“ElectrostaticDischargeInformation”section.

Figure 1. The SATA 2.5 Test Adapter (Plug)

Housing

SATAPlug

4SMAsfor

High‐Speed

Testing

SATA2.5TestAdapterUserManual

Page|4

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

Figure 2. The SATA 2.5 Test Adapter (Receptacle)

4SMAsfor

High‐Speed

Testing

Housing

SATAReceptacle

SATA2.5TestAdapterUserManual

Page|5

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

ProductInspection

UponreceivingtheSATA2.5‐TPAfromWilderTechnologies,performthefollowingproduct

inspection:

Inspecttheoutershippingcontainer,foam‐linedinstrumentcase,andproductfordamage.

Retaintheoutercardboardshippingcontaineruntilthecontentsoftheshipmenthavebeen

inspectedforcompletenessandtheproducthasbeencheckedmechanicallyandelectrically.

Usethefoam‐linedinstrument‐caseforsecurestorageoftheWilderTechnologiesSATA2.5

TestAdapterwhennotinuse.

Locatetheshippinglistandverifythatallitemsorderedwerereceived.

Intheunlikelyeventthattheproductisdefectiveorincomplete,the“LimitedWarranty”

sectiondiscusseshowtocontactWilderTechnologiesfortechnicalassistanceand/orhowto

packagetheproductforreturn.

SATA2.5TestAdapterUserManual

Page|6

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

TheSATA2.5TestAdapterCareandHandlingPrecautions

TheSATA2.5TestAdapterrequirescarefulhandlingtoavoiddamage.Improperhandling

techniques,orusingtoosmallacablebendradius,candamagethecoaxialcableconnections

withintheadapterhousingorthecablesthemselves.Thiscanoccuratanypointalongthe

cable.ToachieveoptimumperformanceandtoprolongtheSATA2.5‐TPA’slife,observethe

followinghandlingprecautions:

CAUTION1:AvoidTorqueForces(Twisting)

Whileindividualcoaxialcableswithinthetestadapterhavesomerotationalfreedom,

twistingtheSATA2.5‐TPAasaunit,withoneendheldstationary,maydamageorseverely

degradeperformance.AdherencetoCaution5(below)helpstoavoidtwisting.

CAUTION2:AvoidSharpCableBends

Neverbendcoaxialcablesintoaradiusof26mm(1‐inch)orless.Neverbendcables

greaterthan90°.Singleormultiplecablebendsmustbekeptwithinthislimit.Bendingthe

SATA2.5‐TPAcableslessthana26mm(1‐Inch)radiuswillpermanentlydamageorseverely

degradetestadapterperformance.

CAUTION3:AvoidCableTension(PullForces)

Neverapplytension(pullforces)toanindividualcoaxialcablethatisgreaterthan2.3kg

(5lbs.).Toavoidapplyingtension,alwaysplaceaccessoriesandequipmentonasurface

thatallowsadjustmenttoeliminatetensionontheSATA2.5‐TPAandcables.Useadjustable

elevationstandsorapparatustoaccuratelyplaceandsupporttheSATA2.5‐TPA.

CAUTION4:ConnecttheSATA2.5‐TPAFirst

Topreventtwisting,bending,orapplyingtensiontothecoaxialcableswhenconnectinga

SATA2.5‐TPA,alwaysattachtheSATA2.5‐TPAtothedeviceundertest(DUT)orcableunder

testbeforeattachinganySMAconnectors.CarefullyaligntheSATAconnectorsandthen

gentlypushtheconnectorstogetheruntilfullyseated.

IftheSATA2.5‐TPAmustbeturnedortwistedtomakeconnectiontotheDUT,avoidusing

theSATA2.5‐TPAhousingalonetomakethisoccur.Trytodistributethetorqueforcesalong

thelengthofthetestsetupandcabling.Ifthisisnotpossible,itisrecommendedtofirst

loosenordisconnecttheSMAconnectionsattheSATA2.5‐TPA,maketheconnectiontothe

DUTandthenre‐tightenorattachthetestequipmentleads.

NOTE:Onlygripthetestadapterhousingwheninsertingor

extractingtheSATA2.5‐TPAtoorfromtheDUT.Pullingdirectlyon

theSATA2.5‐TPAcablesorusingthemtoinserttheSATA2.5‐TPAmay

causedamage.

CAUTION5:CarefullyMakeSMAConnections

ToconnecttheSATA2.5‐TPASMAconnectors,followthesesteps:

1. Holdthecablestationarybygraspingthecableattheblackheat‐shrinksection

neartheSMAconnector.

2. InsertthematingSMAbarrelandhand‐tightenthefree‐spinningSMAnutontothe

connectorwhileavoidingpulling,bending,ortwistingtheSATA2.5‐TPAcoaxial

cable.

SATA2.5TestAdapterUserManual

Page|7

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

3. TheSATA2.5‐TPASMAconnectorshaveflatsthatacceptanopen‐end1/4‐inchor

6.5mmwrench.WhenattachinginstrumentcablestotheSATA2.5‐TPA,itisrecom‐

mendedthattheSATA2.5‐TPASMAconnectorsbemechanicallyheldandthetest

leadsbetightenedtotheequipmentmanufacturer’storquerecommendations,

normally5in‐lbs,usinga5/16‐inchopen‐endwrench.

Ifthetestset‐uprequiresrepositioning,firstloosenordisconnecttheSMAconnectionsto

avoidtwisting,bending,ortension.

NOTE:Adropinsignalamplitudebyhalfor6dbduringthetestingof

achannelmayindicatethatacablehasbeenmechanicallypulled

freeofcoaxialcableconnectionsinternaltotheassembly.Thiscould

bedeterminedbycheckingifthecablehasanylateralplayrelative

totheTPA.ThiswouldonlyoccurwhentheTPAhasexceededthe

pullforceasspecifiedwithinthemechanicalspecification.Ifthe

cablecannotbere‐seated,thetestadapterwillneedtobesentback

tothefactoryforservice.

CAUTION6:IndependentlySupportInstrumentCablesorAccessories

Excessiveweightfrominstrumentcablesand/oraccessoriesconnectedtotheSATA2.5‐TPA

cancausedamageoraffectthetestadapterperformance.Besuretoprovideappropriate

meanstosupportandstabilizealltestset‐upcomponents.

SATA2.5TestAdapterUserManual

Page|8

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

GeneralTestAdapter,Cable,andConnector

Observingsimpleprecautionscanensureaccurateandreliablemeasurements.

HandlingandStorage

BeforeeachuseoftheSATA2.5‐TPA,ensurethatallconnectorsareclean.Handleallcables

carefullyandstoretheSATA2.5‐TPAinthefoam‐linedinstrumentcasewhennotinuse,if

possible.Donotsetconnectorscontactenddown.InstalltheSMAprotectiveendcapswhen

theSATA2.5‐TPAisnotinuse.

VisualInspection

Besuretoinspectallcablescarefullybeforemakingaconnection.Inspectallcablesfor

metalparticles,scratches,deformedthreads,dents,orbent,broken,ormisalignedcenter

conductors.Donotusedamagedcables.

Cleaning

Ifnecessary,cleantheconnectorsusinglow‐pressure(lessthan60PSI)compressedairor

nitrogenwithaneffectiveoil‐vaporfilterandcondensationtrap.Cleanthecablethreads,if

necessary,usingalint‐freeswaborcleaningclothmoistenedwithisopropylalcohol.Always

completelydryaconnectorbeforeuse.Donotuseabrasivestocleantheconnectors.Re‐

inspectconnectors,makingsurenoparticlesorresidueremains.

MakingConnections

Beforemakinganyconnections,reviewthe“CareandHandlingPrecautions”section.Follow

theseguidelineswhenmakingconnections:

Aligncablescarefully

Makepreliminaryconnectionlightly

Totighten,turnconnectornutonly

Donotapplybendingforcetocable

Donotover‐tightenpreliminaryconnections

Donottwistorscrew‐incables

Useatorquewrench,anddonottightenpastthe“break”pointofthetorquewrench

SATA2.5TestAdapterUserManual

Page|9

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

ElectrostaticDischargeInformation

Protectionagainstelectrostaticdischarge(ESD)isessentialwhileconnecting,inspecting,or

cleaningtheSATA2.5‐TPAtestadapterandconnectorsattachedtoastatic‐sensitivecircuit

(suchasthosefoundintestsets).

Electrostaticdischargecandamageordestroyelectroniccomponents.Besuretoperformall

workonelectronicassembliesatastatic‐safeworkstation,usingtwotypesofESDprotection:

Conductivetable‐matandwrist‐strapcombination

Conductivefloor‐matandheel‐strapcombination

Whenusedtogether,bothofthesetypesprovideasignificantlevelofESDprotection.Used

alone,thetable‐matandwrist‐strapcombinationprovideadequateESDprotection.Toensure

usersafety,thestatic‐safeaccessoriesmustprovideatleast1MΩofisolationfromground.

AcceptableESDaccessoriesmaybepurchasedfromalocalsupplier.

WARNING:Thesetechniquesforastatic‐safeworkstationshould

notbeusedwhenworkingoncircuitrywithavoltagepotential

greaterthan500volts.

SATA2.5TestAdapterUserManual

Page|10

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

UserModel

TheSATA2.5TPAsupportsalltestingoftheSATASpecification2.5.Itiscapableofperforming

wellbeyondthescopeofmeasurementsrequired,limitedonlybythespecifications,environ‐

mental,careandhandlingasstatedinthisdocument.

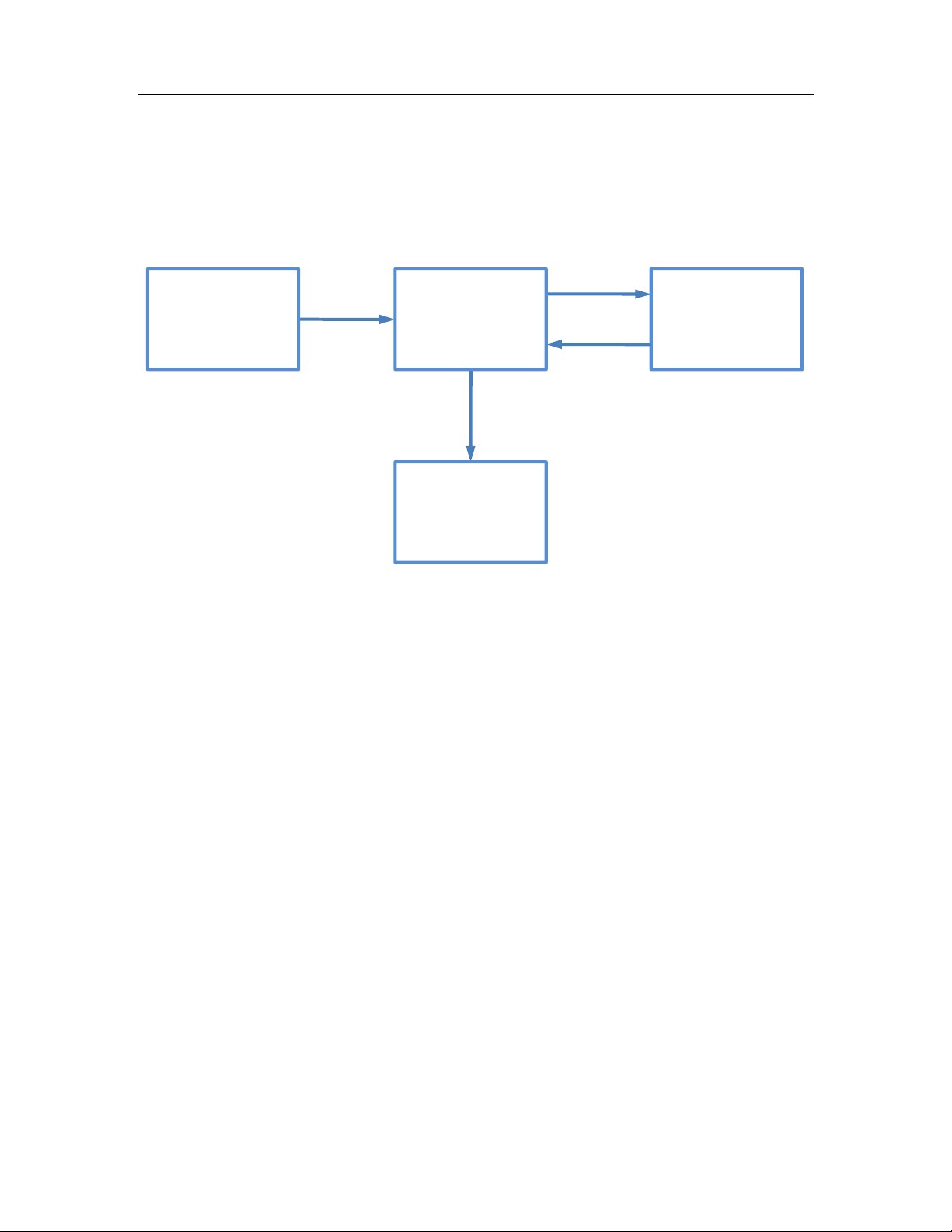

Thefollowingexamplesaresuggestionsforpossibletestingsetups.

Inthisfirstexample,aSATA2.5ReceptacleTPAisusedtotestaSATAdevice:

SATA2.5

Receptacle

TPA

Laboratory

Sourced

Signal

SATADevice

UnderTest

Laboratory

Load

PhysicalLinks

UnderTest

SATA2.5TestAdapterUserManual

Page|11

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

Inthesecondexample,theSATA2.5PlugTPAandaSATAinternalcableassemblyisusedto

testaSATAhost:

SATA

Internal

Cable

SATA2.5

PlugTPA

Laboratory

Sourced

Signal

SATAHost

UnderTest

Laboratory

Load

PhysicalLinksUnderTest

SATA2.5TestAdapterUserManual

Page|12

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

ThethirdexampleshowsaSATA2.5PlugTPAusedtotestahost:

SATA2.5

PlugTPA

Laboratory

Sourced

Signal

SATAHost

UnderTest

Laboratory

Load

PhysicalLinks

UnderTest

SATA2.5TestAdapterUserManual

Page|13

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

ThefourthexampleshowstwoSATA2.5PlugTPAsusedfortestingaSATAcable:

Laboratory

Sourced

Signal/Load

SATA

Cable

SATA2.5

PlugTPA

PhysicalLinksUnderTest

SATA2.5

PlugTPA

MatedConnectors

MatedConnectors

PhysicalLinksUnderTest

SATA2.5TestAdapterUserManual

Page|14

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

ThefifthexampleshowsoneSATA2.5PlugTPAandoneSATA2.5ReceptacleTPAusedfor

testingaSATAextensioncable:

Laboratory

Sourced

Signal/Load

SATA

Extension

Cable

SATA2.5

Receptacle

TPA

PhysicalLinksUnderTest

SATA2.5

PlugTPA

MatedConnectors

MatedConnectors

PhysicalLinksUnderTest

SATA2.5TestAdapterUserManual

Page|15

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

Calibration

TheSATA2.5PlugandReceptacleTestAdaptersarepassivecomponents.Therefore,

calibrationfortheerrorsgeneratedmustoccurwithinthetestinstrumentationthatdrivesthe

SATAreceiverdeviceorlooksattheresponseoftheSATAtransmitterdevice.

TheSATA2.5‐TPA‐C‐2Xcableisusedtoprovide2X‐THRUfunctionality.TheSATA2.5‐TPA‐C‐1X

cableprovides1X‐THRUfunctionalityforcalibration.TheSHORT,OPEN,andLOADfunctionality

isprovidedfromauser‐suppliedcalibrationkit.

Figure 3. Calibration Cables (SATA2.5-TPA-C-2X, Top) & (SATA2.5-TPA-C-1X, Bottom)

SATA2.5TestAdapterUserManual

Page|16

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

SOLT

SHORT,OPEN,LOAD,and2X‐THRU(SOLT)arecalibrationstandardsusedtocompensatefor

errorsassociatedwiththeTPAwhenusedforJittermeasurement,TDR,TDT,andVNAtesting.

SOLTrepresentsthesameelectricallengthandlossesastheTPAthroughtheSATAconnector

pad,andenablesthetestengineertocompensateforthefollowingsixrepeatable,systematic

errorsthatoccurwhenmovingthereferenceplane:

Signalleakageeffects:Directivityerrors

Signalleakageeffects:Crosstalkerrors

Reflectioneffects:SourceImpedanceMismatchingerrors

Reflectioneffects:LoadImpedanceMismatchingerrors

Bandwidtheffects:ReceiverTransmissioninTestEquipmenterrors

Bandwidtheffects:ReceiverReflection‐trackinginTestEquipmenterrors

Theseerrorsneedtobecorrectedoneachport.RefertotheInstrumentManualfor

instructionsontheinstrument’sspecificcalibrationprocess.

NOTE:Thereferenceplaneistheboundary,bothphysicallyand

electrically,betweenthecalibratedanduncalibratedportionsof

thecircuit.Everythingoutsidethereferenceplaneisconsidered

partoftheDUT.Anyinstrumentthatdoesnotusecalibration

definestheDUTasthetotalofexternallyconnectedcomponents.

IftheSATA2.5‐TPA‐C‐1XorC‐2XCalibrationCablesarenotused,all

oftheSATA2.5‐TPAandassociatedcoaxialcables,aswellascables

connectingtheTPAassemblytothetestinstrument,wouldbeapart

oftheDUT.

Non‐repeatableerrors,suchasdriftorrandomerrors,canbereducedbutnotcorrected.

Drifterrorsaggregateovertimeorwithenvironmentalchangessuchastemperatureshift.To

eliminatedrifterrors,performanothercalibration.

Arandomerrorcannotbecorrectedthroughcalibrationsincetheerroroccurredrandomly.

Randomerrorsaretypicallyassociatedwitheithertestinstrumentnoiseortestrepeatability

problems.Reducetestinstrumentnoisebyincreasingsourcepower,loweringtheIF

bandwidth,oraveragingresultsovermultiplesweeps.Reducetestrepeatabilityproblems

throughtheuseofatorquewrenchor,again,byaveragingovermultiplesweeps.

SATA2.5TestAdapterUserManual

Page|17

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

1XTHRU

The1X‐THRUisacalibrationfeatureusedtocalibratetimedomaininstrumentation(for

example,pre‐emphasizedpulsegeneratorsorAWGs,arbitrarywaveformgenerators).1X‐THRU

calibrationcompensatestwoerrorsources–cablelossesandgroupdelay:

CableLosses–CablelossesassociatedwiththeSATA2.5plugTPA,anditsrespectivecabling

that’sconnectedtothetestsource,consistofskinlossand,toalesserextent,dielectricloss.

Pre‐emphasisorde‐emphasisisusedatthesignalsourcetocorrectforthesecablelosses.

Pre‐emphasisisaboostofthesignalleveljustafteranedgetransition;de‐emphasisisa

reductioninthelow‐speedamplitudeofthesignalsource.Typically,onade‐emphasized

signalthelevelshavetoberesettoattainthesameoutputlevels.Resultantsignalsfrom

eitherpre‐emphasisorde‐emphasisareidenticalrelativetotheDUT.

Forthepurposesofthisdiscussion,pre‐emphasiswillbeused.Tosetthepre‐emphasis,first

determinetheamountofsignalboostbyconnectingthesignalsource,viathe1X‐THRUand

therespectivecableusedtoconnecttheDUTtothesourcetoahigh‐speedoscilloscopeora

jittermeasurementdevice.Triggertheoscilloscopeorjittermeasurementdeviceusinga

triggerfromthesource.Thetrigger,asingleevent,indicatesthestartofthesignalbeing

senttotheDUT.Adjustpre‐emphasistomaximizetheeyeopening.

GroupDelay–Groupdelayistheseconderrorsourcefor1X‐THRUcalibration.Whenthe

DUTgeneratesanoutputsignal,itcanbeusedtomeasuredelay.Tocreateabaselinedelay

measurement,connecttheoutputsignalcabletotheinputsignalcableandthe1X‐THRU.To

determinecorrectedDUTdelay,subtractthisbaselinemeasurementfromtheDUTdelay

measurements.

SATA2.5TestAdapterUserManual

Page|18

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

MechanicalandEnvironmentalSpecifications

NOTE:Allspecificationsinthismanualaresubjecttochange.

Table 1. General Specifications

ITEMDESCRIPTION

UsageEnvironmentControlledindoorenvironment

PlugTestAdapterLength(w/standardcables)171.7mm+/‐2mm(6.76inches+/‐.08inches)(Characteristic)

ReceptacleTestAdapterLength(w/std.cables)173.0mm+/‐2mm(6.81inches+/‐.08inches)(Characteristic)

OperatingTemperature0°Cto+55°C(32°Fto+131°F)(Characteristic)

StorageTemperature‐40°Cto+70°C(‐40°Fto+158°F)(Characteristic)

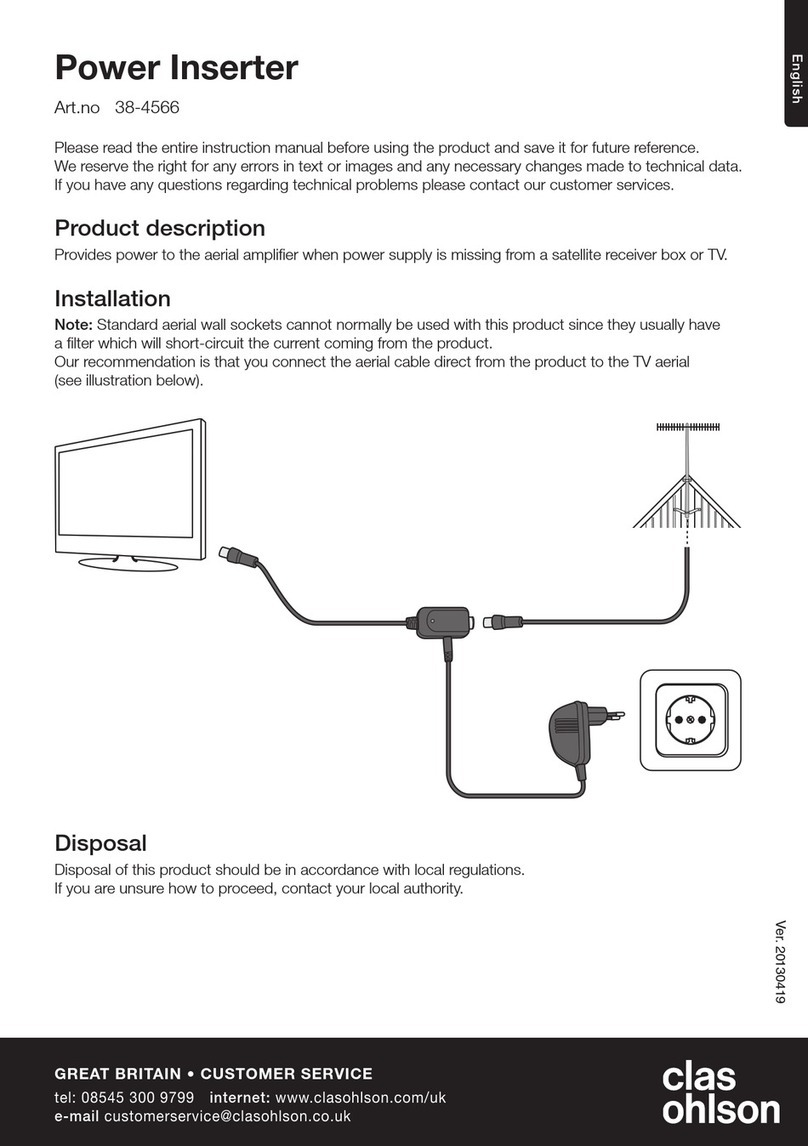

SATA2.5‐TPA‐RCablePinout

TheSATA2.5‐TPA‐RcablesprovidefourSMAconnectors(onelaneofprimarydifferentialTX

andRX).Labelsclearlymarkeachcableorconnector.Thefollowingfigurereferstothepin‐

descriptiontableforthereceptacleconnector.

Figure 4. Cable Connectors (SATA2.5-TPA-R shown)

4SMAsfor

High‐Speed

Testing

ColorIDfor

DifferentialPair

(SeeTable2)

ColorIDfor

DataLinePolarity

(SeeTable2)

Receptacle

Connector

(SeeTable2)

SATA2.5TestAdapterUserManual

Page|19

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

Table 2. SATA 2.5 Receptacle Pin Assignments

PinDescriptionConnectorPin

NumberDestinationNumberColorIDforData

LinePolarity

ColorIDfor

DifferentialPair

(Receptacle)

SignalGroundS1SignalGroundN/AN/A

DrivePrimaryReceiver

PositiveS2DRIVERP+RedYellowLabel

DrivePrimaryReceiver

NegativeS3DRIVERP‐ BlackYellowLabel

SignalGroundS4SignalGroundN/AN/A

DrivePrimary

TransmitterNegativeS5DRIVETP‐ BlackRedLabel

DrivePrimary

TransmitterPositiveS6DRIVETP+RedRedLabel

SignalGroundS7SignalGroundN/AN/A

SATA2.5TestAdapterUserManual

Page|20

©2010,2011WilderTechnologies,LLC

DocumentNo.910‐0011‐000Rev.B

SATA2.5‐TPA‐PCablePinout

TheSATA2.5‐TPA‐PcablesprovidefourSMAconnectors(onelaneofprimarydifferentialTX

andRX).Labelsclearlymarkeachcableorconnector.Thefollowingfigurereferstothepin‐

descriptiontablefortheplugconnector.

Figure 5. Cable Connectors (SATA2.5-TPA-P shown)

4SMAsfor

High‐Speed

Testing

ColorIDfor

DataLinePolarity

(SeeTable3)

ColorIDfor

DifferentialPair

(SeeTable3)

PlugConnector

(SeeTable3)

Table of contents

Other Wilder Technologies Adapter manuals