Wilger Installation and Operation Manual

Wilger Electronic Flow Monitoring System Page | 5

3. Introduction

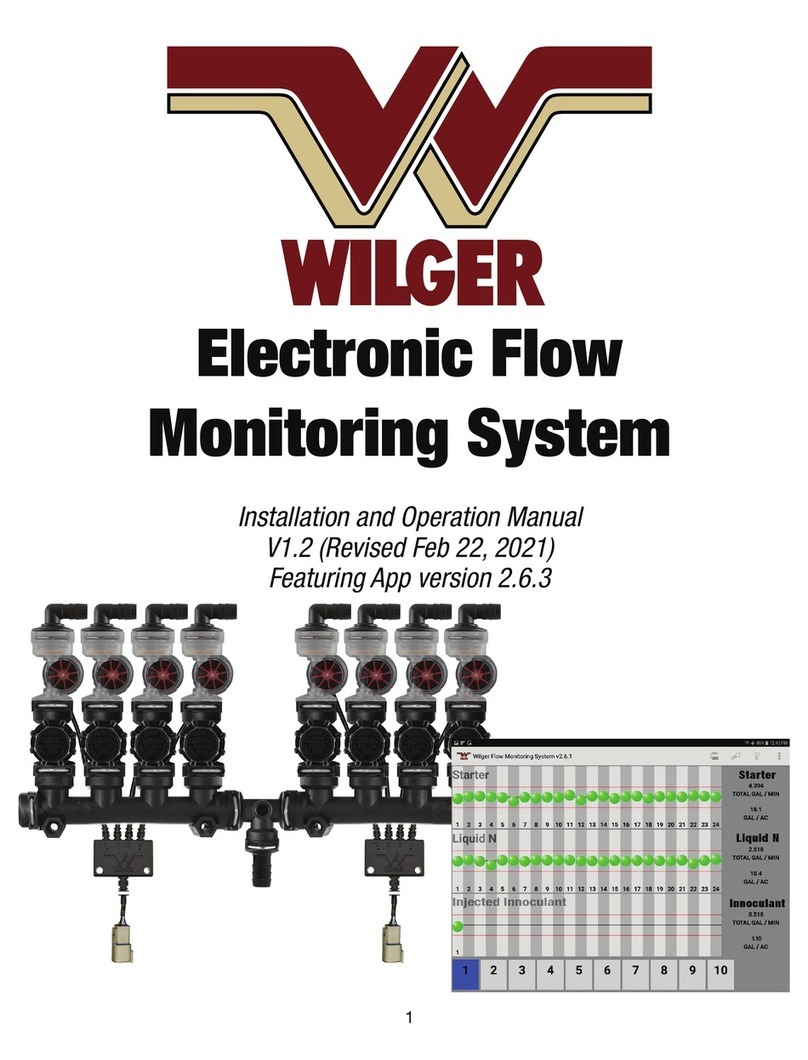

The Wilger Electronic Flow Monitoring System (EFMS) is a compact flowmeter that

can be used row-by-row on liquid fertilizer or chemical application equipment. The

flow meter is paired with a tablet, or manufacturer’s monitor to provide accurate

monitoring for both blockage and flow rate irregularity.

Similar to visual ball flow indicators, the Wilger Electronic Flow Monitoring System

shows variations in flow caused by blocked lines, incorrect orifices, or blown

product hoses. However, the Wilger EFM System provides the added benefit of

indicating the actual flow (not just relative flow) for each row. This information is

conveniently displayed on a screen in your cab.

The EFM system utilizes a paddle-wheel flowmeter, with patented stabilizing flow

jets, that maintains accuracy across the flow range of 0.04 US GPM to 1.5 US GPM

(0.15L/min to 5.6L/min), without significant pressure drops. The EFM system

accurately monitors flow on each outlet or product run, which ensures the operator

has complete and comprehensive flow information. The flowmeter can provide a

40:1 flow range, pairing stabilizing flow jets appropriate for the users’ operational

flow range.

The Electronic Flow Monitoring app (Android OS) receives sensor information from

the flowmeters via an Electronic Control Unit (ECU). The ECU establishes a local WiFi

connection with the tablet, so there are no communication harnesses needed

between the implement and the cab.

EFM System Components

Plumbing

The Electronic Flow Monitoring system uses O-ring Seal (ORS) plumbing, which is

ultimately adaptable to any application equipment. However, the system typically

requires:

Plumbing manifolds, which split the flow to each flow run

EFM flowmeters, each of which is equipped with:

A flow jet, selected for the anticipated flow range

An orifice, which determines the application flow rate

Check valves (recommended) that allow flow to be manually shut off

[OPTIONAL] Ball Flow Indicators, which can be installed to add visual

indication of flow in addition to the digital display.