Contents

OVERVIEW ................................................................................................................... 1

About This Document...............................................................................................................................1

Manufacturer’s Address............................................................................................................................1

Important Safety Information................................................................................................................2

Warnings, Cautions, Notes...............................................................................................................3

Warning Labels....................................................................................................................................5

Electrical Safety ...................................................................................................................................5

Grounding.............................................................................................................................................5

Environmental Information (WEEE) .............................................................................................6

UV Source Lamps Disposal..............................................................................................................6

Electromagnetic Compatibility (EMC).........................................................................................7

Supplier’s Declaration of Conformity ..........................................................................................8

Special Warnings and Information ...............................................................................................9

Equipment Used in Hazardous Locations............................................................................9

About the Analyzer................................................................................................................................. 10

SPECIFICATIONS........................................................................................................ 11

APPROVALS AND CERTIFICATIONS ......................................................................... 13

Directives and Standards......................................................................................................................13

Analyzer Marking.....................................................................................................................................14

INSTALLING THE 993X ANALYZER........................................................................... 15

Pre-Installation Requirements ............................................................................................................15

Personnel Technical Level Required for Installation............................................................15

Unpacking and Inspecting the Equipment............................................................................ 16

Analyzer Site Preparation..............................................................................................................17

Space Requirements....................................................................................................................... 17

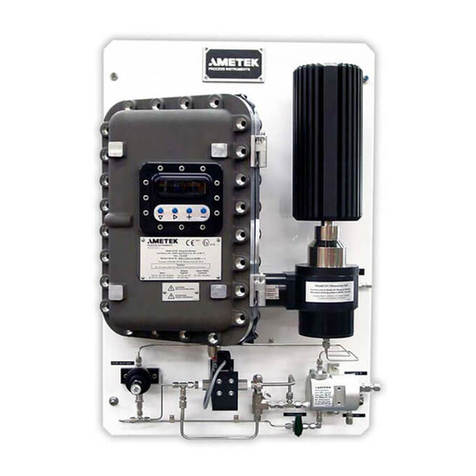

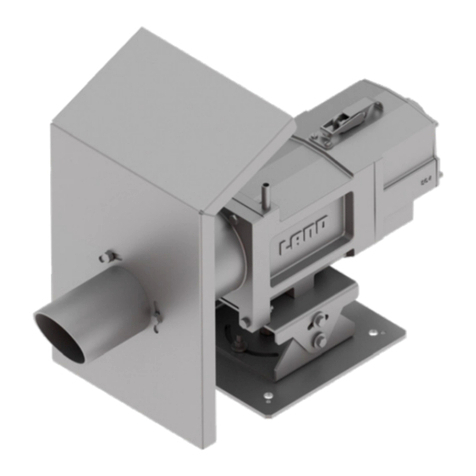

Mechanical Installation.......................................................................................................................... 18

Analyzer Installation Guidelines.................................................................................................18

Tools, Equipment, and Supplies Required for Installation................................................ 19

Analyzer Installation Drawings...................................................................................................20

Installing the Optical Bench Assembly ....................................................................................22

Removing the Optical Bench Assembly .................................................................................. 27

Installing a Power-Disconnect Switch and/or Breaker (Supplied by Customer/

End User) ....................................................................................................................................33

Installing the Sample System...................................................................................................... 34

Sample Prerequisites...............................................................................................................34

Installing and Connecting the Sample and Vent Lines...................................................35

Connecting the Zero Gas........................................................................................................37

Contents | i

PN 903-8820, Rev A