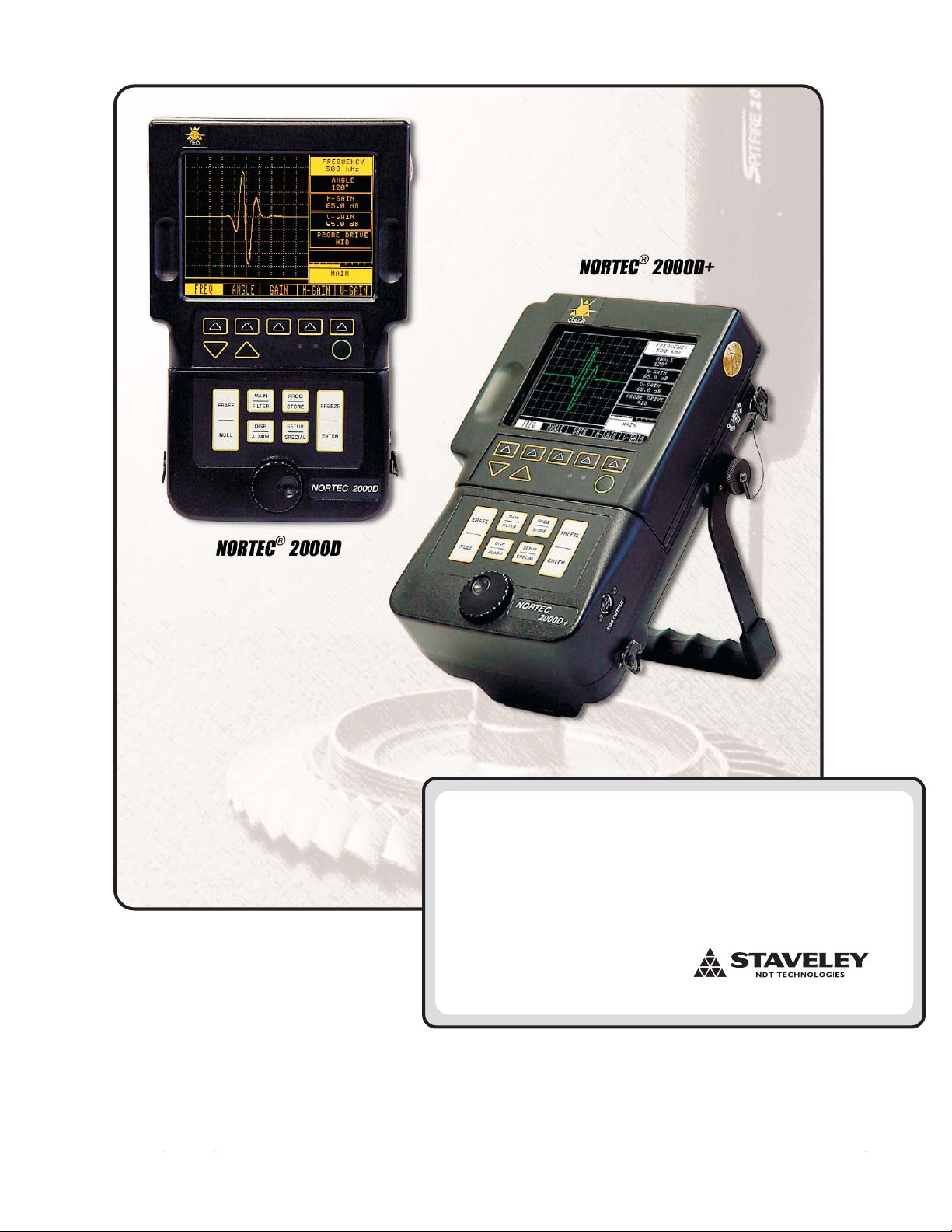

Nortec®2000D Operation Manual

Rev 6 (3/2005) ix

Table of Contents

1.0 Nortec®2000D Preparation for Operation....................................................................... 1

1.1 Unpacking the Nortec® 2000D ......................................................................................................................... 2

1.2 Nortec®2000D/D+ Optional Accessories ........................................................................................................ 2

1.3 Initial Inspection Checklist ............................................................................................................................... 3

1.4 Power Requirements ....................................................................................................................................... 4

1.5 Ni-MH Battery Characteristics ......................................................................................................................... 6

1.6 Li-Ion Battery Pack Characteristics

1.7 Charging the Ni-MH/Li-Ion Battery Pack ......................................................................................................... 7

1.7.1 UBC Specifications .............................................................................................................................. 7

1.7.2 Charger Status Indicators .................................................................................................................... 7

1.7.3 Charger Operation Instructions ........................................................................................................... 8

1.7.4 Battery Safety ...................................................................................................................................... 8

1.7.5 Battery Characteristics ........................................................................................................................ 9

1.7.6 UBC Spare Parts ................................................................................................................................. 9

1.8 Operating Environment.................................................................................................................................... 10

2.0 Nortec®2000D Technical Data ......................................................................................... 11

2.1 Nortec®2000D Technical Specifications ............................................................................................. 12

Basic Performance .......................................................................................................................... 12

Basic Performance (cont’d) ............................................................................................................. 13

Inputs / Outputs ............................................................................................................................... 14

Additional Features.......................................................................................................................... 14

General ............................................................................................................................................ 15

3.0 Nortec®2000D Control Descriptions............................................................................... 17

Instrument Controls ......................................................................................................................................... 18

3.1 Power Button ................................................................................................................................................... 19

3.2 Soft Keys.......................................................................................................................................................... 19

3.3 INC/DEC Arrow Keys ....................................................................................................................................... 19

3.4 LCD/EL Display................................................................................................................................................ 19

3.4.1 EL Hi-Brite Display............................................................................................................................... 21

3.5 SmartKnob™ ................................................................................................................................................... 22

3.6 Immediate Execution Keys .............................................................................................................................. 22

3.7 Function Keys .................................................................................................................................................. 22

3.7.1 Menu Tree .......................................................................................................................................... 24

3.8 Basic Functions ............................................................................................................................................... 25

3.9 Alarm Operation............................................................................................................................................... 29

3.9.1 Box Alarm............................................................................................................................................ 30

3.9.2 Polar Alarm .......................................................................................................................................... 31

3.9.3 Sweep Alarm ........................................................................................................................................ 32

3.10 Dual Frequency Mode...................................................................................................................................... 34

3.11 Program Storage.............................................................................................................................................. 37

3.12 Data Storage .................................................................................................................................................... 40

3.13 Setup Menu...................................................................................................................................................... 45

3.14 Special Functions............................................................................................................................................. 53

3.15 Waterfall Display Function ............................................................................................................................... 54

3.16 Conductivity Mode ........................................................................................................................................... 56

3.16.1 Conductivity Calibration ....................................................................................................................... 58

3.16.2 Conductivity Alarm Menu ..................................................................................................................... 59

3.16.3 Liftoff Alarm Menu ................................................................................................................................ 60

4.0 Nortec®2000D Applications............................................................................................. 61

4.1 Impedance Plane Display-Conductivity Curve ................................................................................................ 62

4.2 Surface Flaw Detection.................................................................................................................................... 64

4.3 Second Layer Crack Detection........................................................................................................................ 66

4.4 Thickness Measurement ................................................................................................................................. 68

4.5 Conductivity — Sorting .................................................................................................................................... 71

4.6 Conductivity — Liftoff Measurement (Paint Layer Thickness Measurement)................................................ 73

4.7 Corrosion Detection with Dual Frequency....................................................................................................... 75

4.8 Scanner Operation........................................................................................................................................... 80

4.9 Waterfall Display Functions ............................................................................................................................. 81