06

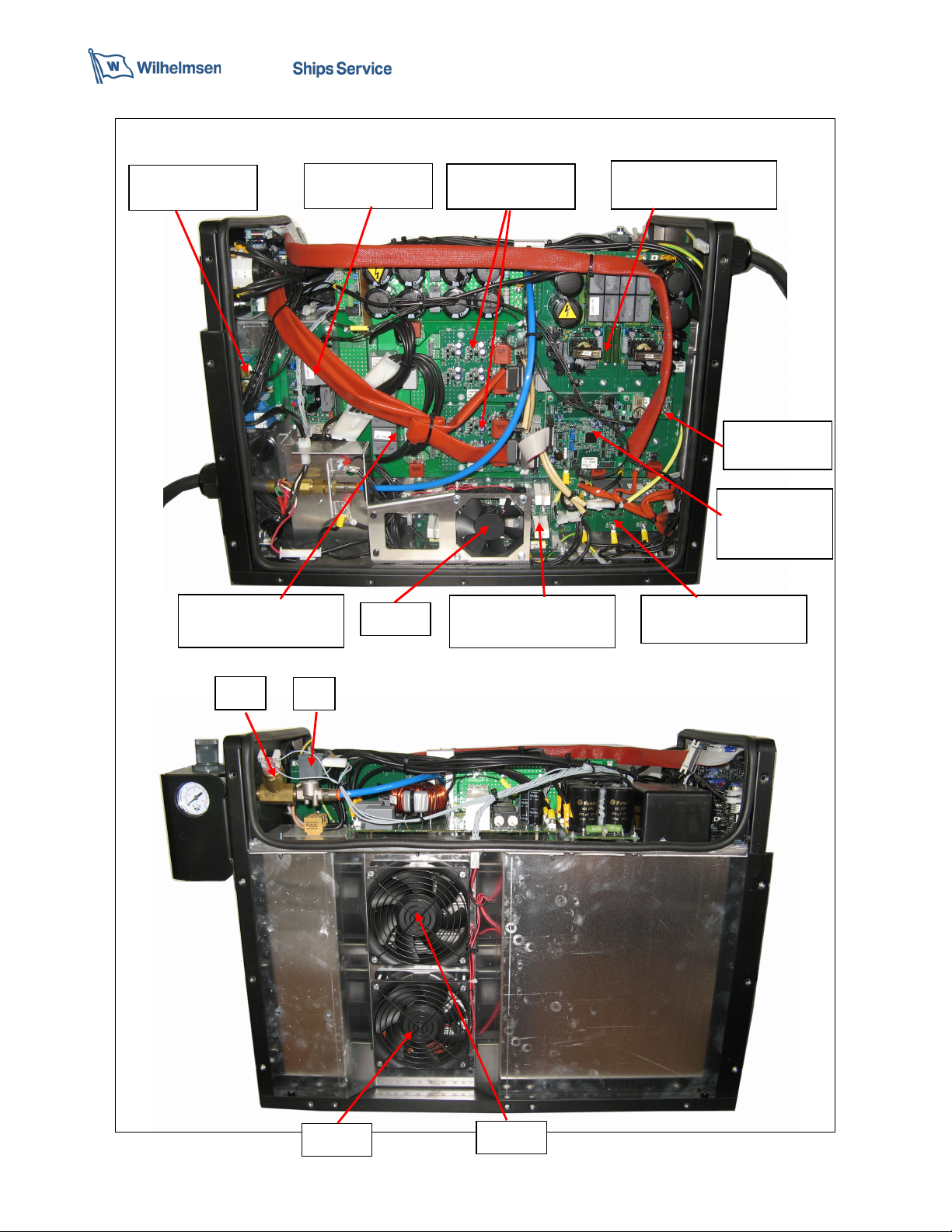

-Boost power board (PCB5) for

NTC 3 and 4.

- The sensor under the secondary

inverter board for NTC 5.

During cutting, the Circuit Breaker trip.

Make sure the cutting current

does not require input power

greater than what supplied by

the line or the fuse is too low.

Check the fuse size.

230V 1Ph: 25A

400V 3Ph: 16A

440V 3Ph: 16A

No compressed air output.

Solenoid valve damaged.

Front panel logic board

PCB10 faulty.

-When you push test air, check

the supply voltage of EV

(PICTURE 15).

If the voltage is present and no air

output the Solenoid valve must be

replace.

-If above checks are all correct.

The logic board PCB10 is faulty

and to be replace.

Always compressed air out when I turn on

the machine

Front panel logic board

PCB10 faulty.

-If above checks are all correct.

The logic board PCB10 is faulty

and to be replace.

Maximum output current always 60A

Phase failure.

The generator is working in

single phase.

Check the input of the 3 phases.

The arc does not transfer to the workpiece Ground clamp problem

-Clean the area where the ground

clamp contacts the workpiece to

ensure a good metal-to-metal

contact.

-Inspect the ground clamp for

damage and rapair it if necessary.

-Move the torch closer the

workpiece and fire the torch again.

Error message

TRI message

Indicates that machine has

been turned on while pressing

torch switch.

Release the trigger and restart the

power supply.

Error message

PIP message

Indicates that the

consumables are not correctly

mounted.

Check the correct assembly of

consumables (PICTURE 20).