9938 / 1927300 / 3

uomiEnglishDeutschFrançais Nederlands venska

X8

d

X9

X2

c

b

X8 Hitsausjänniteliitäntä, + napa

Anslutning av svetskabel, pluspol

Welding voltage connection, positive

Schweißspannungsanschluß, Pluspol

Lasspanningsaansluiting, pluspool

Connecteur tension de soudage, positif

X9 Hitsausjänniteliitäntä, napa

Anslutning av svetskabel, minuspol

Welding voltage connection, negative

Schweißspannungsanschluß, Minuspol

Lasspanningsaansluiting, minpool

Connecteur tension de soudage, négatif

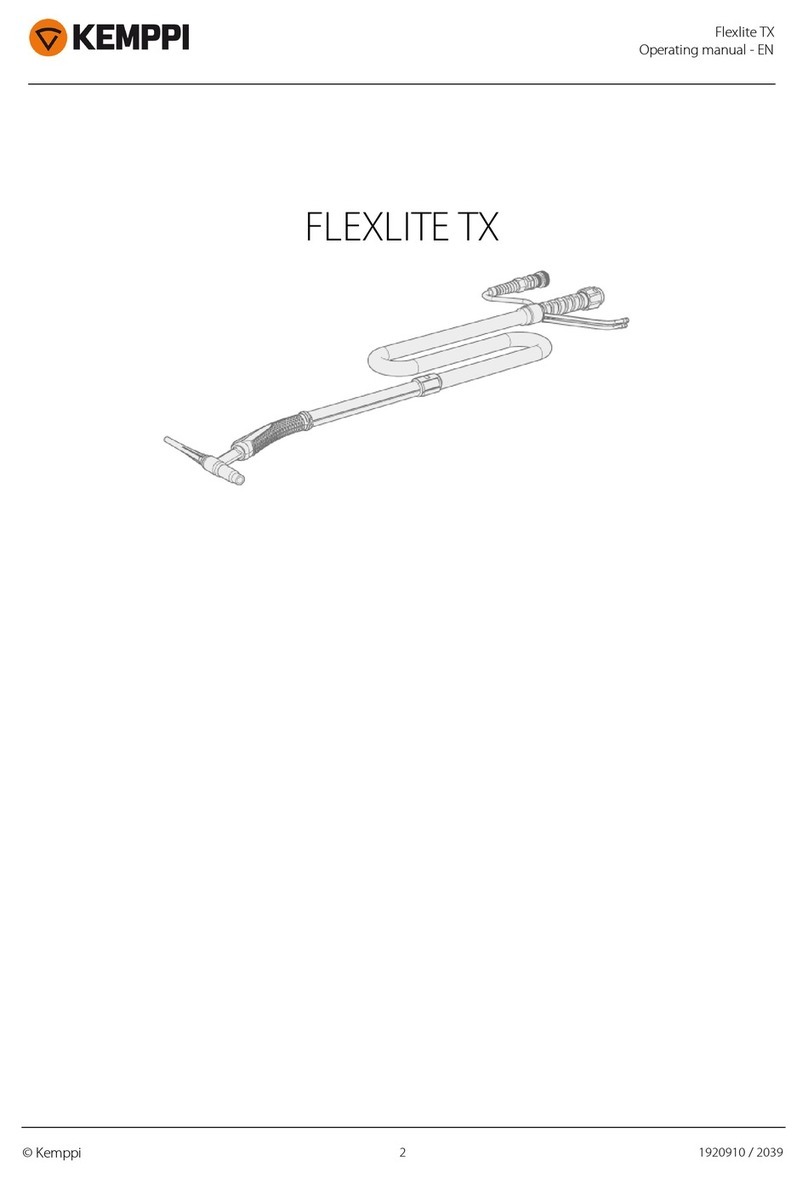

aJäähdytysnesteliitäntä, hitsauspoltin

Anslutning f r kylvätska, svetsbrännare

Cooling liquid connection, welding

Anschluß für Kühlflüssigkeit, Schweiß-

brenner

Aansluiting voor koelvloeistof, lasbrander

Connecteur liquide refroidissement/

torche

bJäähdytysnesteliitäntä, sy tt

Anslutning f r kylvätska, inmatning

Cooling liquid connection, supply

Anschluß für Kühlflüssigkeit, Einlauf

Aansluiting voor koelvloeistof, toevoer

Connecteur alimentation liquide de

refroidissement

4. Jäähdytysnesteletku, sy tt

Kylvätskeslang, inmatning

Cooling liquid hose, supply

Kühlflüssigkeitschlauch, einlauf

Vloeistofslang, toevoer

Alimentation liquide de refroidissement

5. Ohjauskaapeli

Man verkabel

Control cable

Steuerkabel

Stuurkabel

Câble de commande

6. Ohjauskaapeli

Man verkabel

Control cable

Steuerkabel

Stuurkabel

Câble de commande

7. Suojakaasuletku

Skyddsgasslang

Shielding gas hose

Schutzgasschlauch

Beschermgasslang

Tuyau gaz de protection

8. WU:n verkkoliitäntäjohto

Nätkabel f r WU

Mains cable for WU

Netzkabel für WU

Netkabel voor WU

Câble dalimentation pour WU

9. TIG-poltin, kaasujäähdytteinen

TIG-brännare, gaskyld

TIG-torch, gas-cooled

WIG-Brenner, gasgekühlt

WIG-brander, gasgekoeld

Torche Tig, refroidie gaz

10. TIG-poltin, nestejäähdytteinen

TIG-brännare, vätskekyld

TIG-torch, liquid-cooled

WIG-Brenner, flüssikeitsgekühlt

WIG-brander, vloeistofgekoeld

Torche Tig, refroidie par liquide

11. Paluuvirtakaapeli

Återledare

Retur cable

Stromrückleitungskabel

Stroomterugvoerkabel

Câble de masse

12. Kaukosäät välikaapeli

Mellankabel f r fjärreglage

Interconnection cable for remote control

Zwischenkabel für Fernregelung

Tussenkabel voor afstandsbediening

Câble intermédiaire pour commande à

distance

13. Kaukosäät välikaapeli

Mellankabel f r fjärreglage

Interconnection cable for remote

control

Zwischenkabel für Fernregelung

Tussenkabel voor afstandsbediening

Câble intermédiaire pour commande à

distance

1-7. Toimitetaan välikaapelinippuna

Levereras som mellankabelbunt

Delivery as interconnection cable bundle

Lieferung als Zwischenkabelbündel

Levering als tussenkabelbundel

Livré en un faisceau

cJäähdytysnesteliitäntä, paluu

Anslutning f r kylvätska, retur

Cooling liquid connection, return

Anschluß für Kühlflüssigkeit, Rücklauf

Aansluiting voor koelvloeistof, retour

Connecteur retour liquide de

refroidissement

dSuojakaasuliitäntä, sy tt

Anslutning f r skyddsgas, inmatning

Connection for shielding gas, supply

Anschluss für Schutzgas, Einlauf

Aansluiting voor beschermgas, toevoer

Connecteur alimentation gaz de protection

1. Hitsausvirtakaapeli, + napa

Svetsstr mkabel, pluspol

Welding current cable, positive

Schweißstromkabel, Pluspol

Lasstroomkabel, pluspool

Câble courant de soudage, positif

2. Hitsausvirtakaapeli, napa

Svetsstr mkabel, minuspol

Welding current cable, negative

Schweißstromkabel, Minuspol

Lasstroomkabel, minpool

Câble courant de soudage, négatif

3. Jäähdytysnesteletku, paluu

Kylvätskeslang, retur

Cooling liquid hose, return

Kühlflüssigkeitschlauch, Rücklauf

Vloeistofslang, retour

Tuyau retour liquide de refroidissement