7

• One, optional ow check valve (recommended for

parallel pumping systems, provided by Wilo).

• Installation and operation instructions (provided by

Wilo).

• Three wire nuts and three cable ties (provided by Wilo).

4.2 Installation

It is recommended that full port isolation ball valves be

placed on the supply and return lines for the pump so that

the pump can be serviced without having to drain the

system. Make sure that the pump is pumping away from the

bladder tank. Pumping toward the tank during extremely

low speeds, in rare cases, can cause the pump to become

air bound and stop the ow of water. It is recommended

that the system includes an air vent device at highest point

of the system.

• Install the pump in a vertical or horizontal position.

Refer to Fig.2a Horizontal Mounting and 2b Vertical

Mounting-Page 2

• Adjust the display to the proper orientation. The default

orientation for the display view is in the horizontal

position. In a vertical installation, remove the four hex

head bolts (4 mm) and turn the pump counterclockwise

90° and reinsert the hex bolts and tighten in a crisscross

pattern evenly until tight. Refer to Fig.2c-Page 2-

Rotating the Display.

• The installation and connection dimensions (connection

anges and pump footprint) are given in Fig.3-Page

3-Dimensional Data

• It is strongly recommended to capture sediment by using

permanent magnet separator upstream of the pump.

Using the supplied O-ring gaskets, install them on the

supply and return body anges of the pump, Tighten the

ange bolts evenly to the pump. Only use the O-ring

gaskets provided, any other gaskets used will void the

warranty. Refer to Fig. 5a-Page 4-Installing the Gaskets

The flow check option should be used when parallel

pumping is the primary piping conguration. When used,

please insert the ow check into the discharge neck until

it locks into place. Make sure the check moves freely. Refer

to Fig.2c-Page 2 - Rotating the Display.

WARNING! Risk of injury due to hot surfaces!

The pump must be positioned so that someone cannot

come into contact with the hot pump surfaces while in

operation.

If you are using differential temperature as the method of

control, zip-tie the probes to the supply and return piping.

Fig.4 -Page 3-Probe Location. If you have issues (e.g. not

enough wire length available to attach the probe to the

return piping), it is recommended to switch the control

mode from the Delta-T mode to the Auto mode.

This pump’s basic function is to pump hot or cold water or

water with 50% ethylene or propylene glycol.

NOTE: If introducing propylene or ethylene glycol into the

system, it is important to dose downstream of the pump.

DANGER! Risk of explosion!

The pump must not be used to pump ammable liquid such as

rapeseed oil and gasoline. Allowed liquids should be thin, clean,

non-corrosive and non-explosive and should not contain any

solid particles, ber or mineral oil.

4.3 Application areas:

Heating, Ventilation and Air-Conditioning:

• Boilers

• Induction heating

• Heat exchangers

• Temperature control systems

• Cooling circuits

5. Technical data

5.1 Technical data

- Ambient temperature range: 0°F -104°F

- Max relative humidity: 95%

- Degree of protection: IP42

- Max ow: 14.5 Gallons Per Minute

- Max dBA: 42

- Max system pressure: 145 PSI (10 BAR)

- Fluid temperature range: 36°F -230°F

WARNING CONCERNING CONDENSATION

To avoid condensation in the control box and stator, the

temperature of the pumped liquid must be always higher than

ambient temperature . In cooling circuits it is recommended to

insulate the pump housing. DO NOT INSULATE THE MOTOR!

5.2 Motor Information

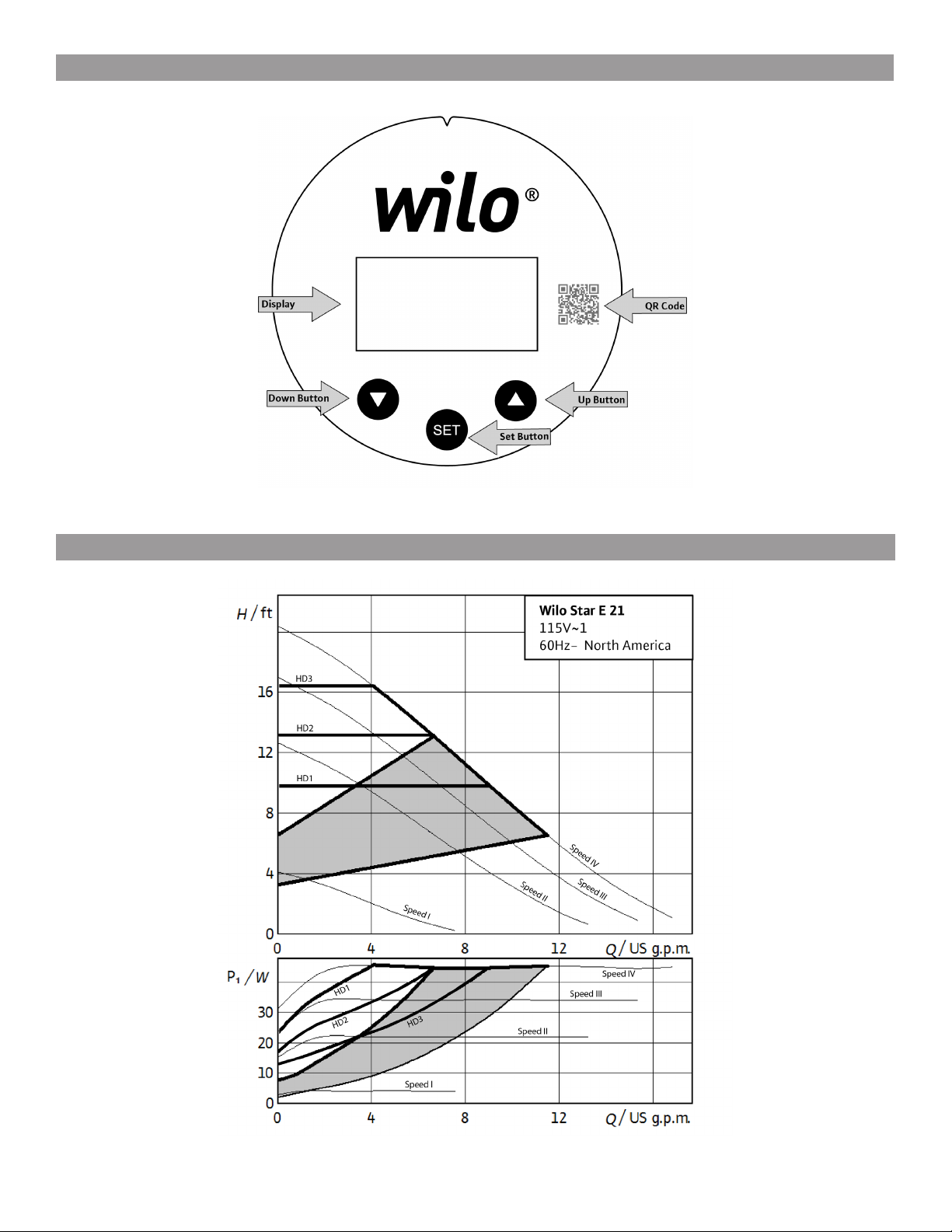

The Star E 21 pump is equipped with permanent-

magnet motor and differential temperature controller,

capable of automatically & continuously adjusting motor

performance to meet the actual needs of system.

5.3 Accessories

Original accessories are available for the Wilo-Star E 21.

The accessories must be ordered separately.

6. Electrical connections

Wire the pump from the boiler pump relay to the conduit

box. Note: Please follow the appropriate national and local

electrical codes. Two 3/4” knock-outs are available for

wiring; one on the side and one on the back. Liquid-tite,

BX, or Rigid conduit are the preferred methods to protect

the wiring. Fig. 6-page 4-Wiring diagram.

DANGER! Danger of death!

National Electrical Codes (NEC), local codes and

regulations must be followed.

WARNING! Electrical shock hazard!

All electrical work must be conducted by a qualied

electrician! Make sure that the supply voltages are

Installation and operating instructions - Wilo-Star E 21

Liquid Temperature <185°F 194°F 230°F

Minimum Inlet Pressure 0.725 PSI 4.1 PSI 14.5 PSI

1.68 Ft. of Hd 9.5 Ft. of Hd 33.5 Ft. of Hd