1.1 SCOPE

SECTION 1

INTRODUCTION

This manual describes the Wilson Laboratories' SX-530 Disk Memory Exerciser. The manual

is

written using

the storagemodule (SMD) type interface

as

the basis, however, interface adapteraddendums are includedas part

of

this document so the reader may easily adapt the methods described herein tootherdrive types supported by

the SX-530 Exerciser.

This manual consists

of

six sections and addendums

as

required and described briefly

as

follows:

Section I

Section 2

Section 3

Section 4

Section 5

Section 6

Addendum

Introduction and general desription including physical and environmental charac-

teristics.

A briefexplanation

of

disk drive theory to establish common terminology.

A functional and physical description

of

the

Exerciser including assembly and adapter

removal

and

reinstallation infonnation.

A description

of

the controls and indicators

in

a mannerso they

may

be easily found and

referenced.

General operating procedures

as

they relate

to

the

Exerciserfunctions and modes.

A group

of

suggested special procedures that

may

be perfonned during acceptance

testing and

field

maintenance applications.

Each addendum describes an 1/0 Interface Adapter Card for a specific drive type and

associated mini-panel assembly (as required). Also included are applicable operating

instructions

and

adiscussion

of

the

PROM

and

its

fonnat timing for that interface.

SX-530 Exerciser Theory

of

Operations and Logic Description

is

provided

in

a separate manual which can be

obtained from the factory

by

signing a non-disclosure letter ofagreement.

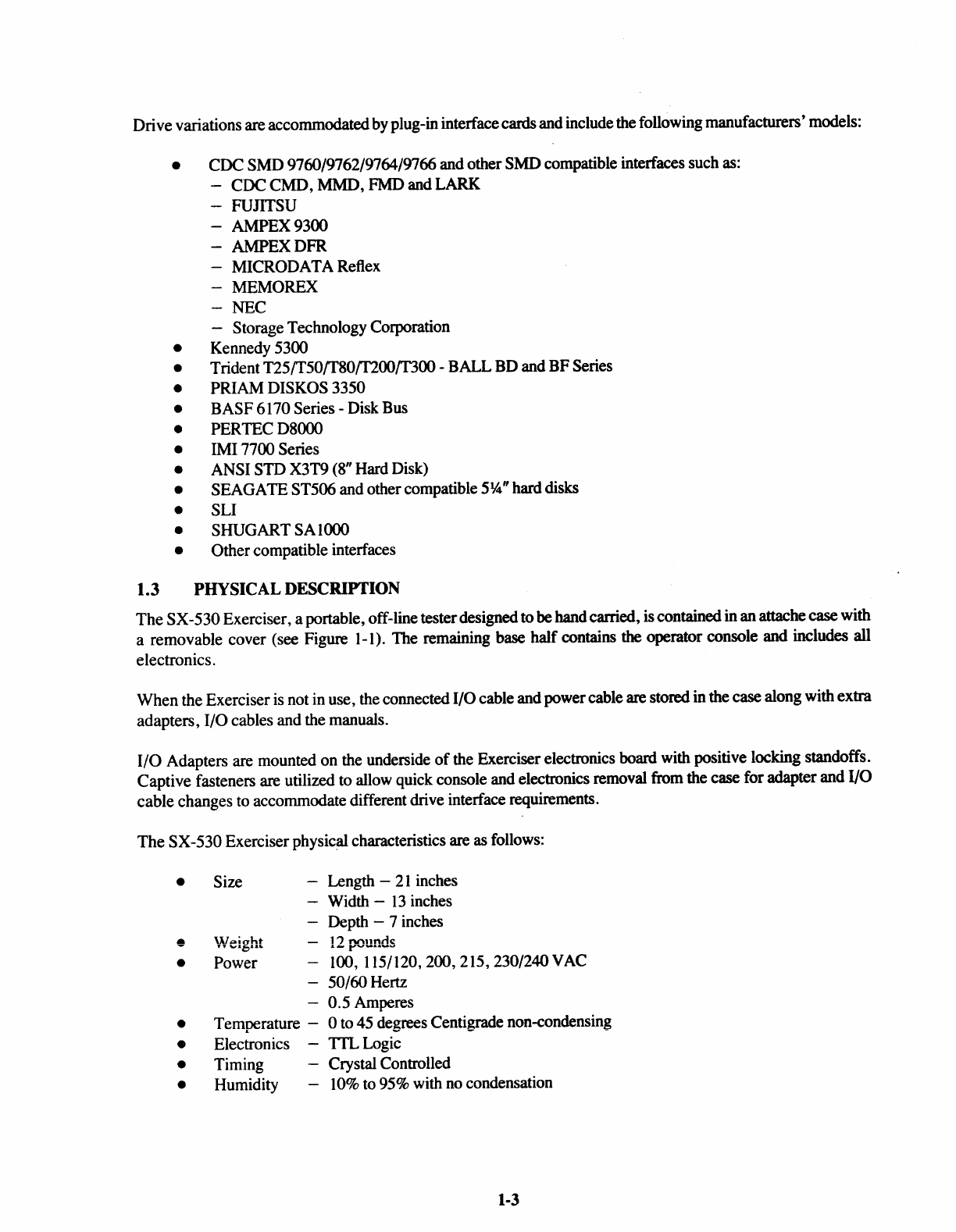

1.2 GENERAL

The SX-530 Disk Memory Exerciser, Figure

I-I,

is

designed

for

testing disk drive models with Storage Module

type interface and Winchester

fixed

andlor removable cartridge type disk drive

in

either

5JA",

8",

or

14"

media

from most manufacturers. It·can

be

used for all off-line drive exerciser/test functions including manufacturing

QC

testing

to

insure trouble-free operation before shipment,

QA

incoming inspection,

field

service testing to

isolate and repair drive problems

and

for engineering evaluation

of

peripherals.The SX-530

is

housed in a

suitcase type enclosure which makes it convenient for all applications.

The SX-530 reads and writes data

in

four fonnatted modes using a selection

of

three

fixed

data patterns and one

userprogrammabie data pattern. Errorindicators show

the

type

and

iocation

of

errors and manuai controis permit

single step orcontinuous running

with

error indication orstop

on

errorcapability.

Single steps, seek delay, alternate set, stop on error, offset

and

marginal strobe control combine

to

make trouble

shooting

by

t'le operator a quick and easy function. Trouble shooting operntion includes

the

ability to

intr"uduce

errors and check out specific areas

of

drive perfonnance.

1-1