4REV B

OPM-101

PREPARING THE UNIT

UNPACKING

CAUTION: EQUIPMENT DAMAGE

When you unpack your new generator, be sure to remove all of the

information sheets and manual from the carton.

1. As you receive your unit, it is critical to check it for any damage. If

any damage is noted, it is always easiest to refuse the shipment and

let WINCO take care of the freight claim. If you sign for the unit, the

transferoftheownershiprequiresthatyoulethefreightclaim

2. Before proceeding with the preparations of your new generator

for operation, take a couple of minutes to ensure the unit you have

receivedisthecorrectmodelandreviewthespecicationpagesinthis

manual to ensure that this unit meets your job requirements.

UNIT INSTALLATION

Plans for installation should be prepared with proper attention to

mechanical and electrical engineering detail to assure a satisfactory

system installation. The information in this manual is offered as a

guidetonalizingyourinstallationplans.Theinstallationsequenceis

summarized below.

HP AMPS

RUNNING

STARTING

AMPS

SP CAP RI

1/6 3.2 16 TO 22 6 TO 13 5 TO 8

1/4 4.5 22 TO 32 9 TO 8 7 TO 12

1/3 5.2 26 TO 35 10 TO 21 8 TO 17

1/2 7.2 NOT MADE 14 TO 29 11 TO 18

1 13.0 NOT MADE 26 TO 52 20 TO 33

Theguresgivenaboveareforaverageloadsuchasablowerorfan.

If the electric motor is connected to a hard starting load such as an air

compressor, it will require more starting current. If it is connected to a

light load, or no load such as a power saw, it will require less starting

current. The exact requirement will also vary with the brand or design

of the motor.

Self- exciting generators respond to severe overloading differently

that utility power. When over loaded, the engine is not able to supply

enough power to bring electric motor up to operating speed. The

generator responds with high initial starting current, but the engine

speed drops sharply. The overload may stall the engine. If allowed to

operate at very low speeds, the electric motor starting winding will burn

out in a short time. The generator winding may also be damaged.

PLAN THE INSTALLATION

Generally, two-bearing generators are used on portable equipment. For

best service consider the following:

1. All electrical equipment should be protected from excessive moisture.

Failure to do so will result in deterioration of the insulation, short

circuits, and grounds.

2. The generator should be installed in a sheltered area. If the unit must

be left in the open, it should always be protected with a weather cover

such as a tarp or large piece of canvas after each use to keep out water

and dust.

CAUTION: EQUIPMENT DAMAGE

Always allow the generator and prime mover to cool before covering

with a ammable weather covering.

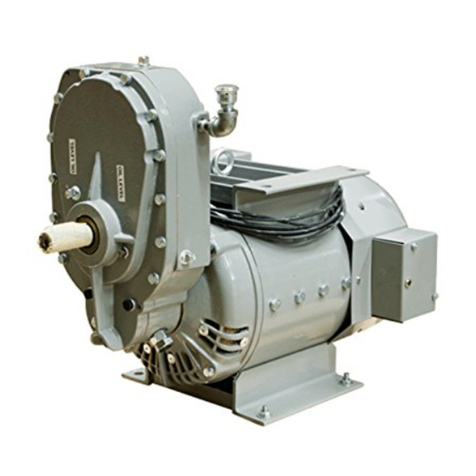

MOUNTING

CAUTION: EQUIPMENT DAMAGE

The generator must be mounted with the engine to a common rigid

base to prevent stress on the engine and generator shafts and bearings

do to vibration displacement. For permanent installations, the engine-

generator is usually mounted on a sub-frame which can be shock

mounted with neoprene pads on the main frame.

Before proceeding with installation, be sure that you have completely

read and understood the assembly and installation instructions.

Anenginewithadequatehorsepowerandacloseregulated(xed

speed) governor is required for satisfactory operation of this generator.

About 1.4 horsepower is required to produce 1,000 Watts of generator

outputpowerassuming100%efciencyofboththeengineandthe

generator.However,duetoengineandgeneratorefcienciesof80

to 90%, the loss of power due to engine driving accessories such

as cooling fans, battery charging alternators, etc. friction losses and

slippage in the drive pulleys and belts, the general conservative rule of

thumb allowing approximately two (2) horsepower for every 1,000 Watts

of generator output is much more realistic. For example, the 2,400 Watt

generator output will require a 4.8 horsepower engine for full output,

good speed/voltage regulation, and satisfactory load performance.

When determining the prime mover/generator pulley ratio to drive the

generator at the correct operating speed, bear in mind the power rating

of most prime movers (usually an engine) varies with speed. It produces

more power at higher speeds, less when slowed. The prime mover

must be fast enough to reach desired horsepower for good generator

operation.

The drive belt system must be of adequate size and must be tight

enough to power the generator without slippage. Be careful not to

over-tighten to the extent that it puts excessive strain on the bearings.

Doing so can cause bearing failure and other possible damage to the

generator.

Alignment of the generator to the prime mover is important.

Misalignment of the pulleys will cause excessive belt and pulley wear

and unnecessary stress on the prime mover.