1.5.3 WHAT IF THE BRACKET IS ALIGNED

INCORRECTLY?

• Noproblem:loosenmountingbolts901andusethe

rubber mallet to move the clamps along the cheeks

900/910 until the alignment is satisfactory.

1.5.4 MOUNTING THE SYSTEM ON THE

MOUNTING BRACKET

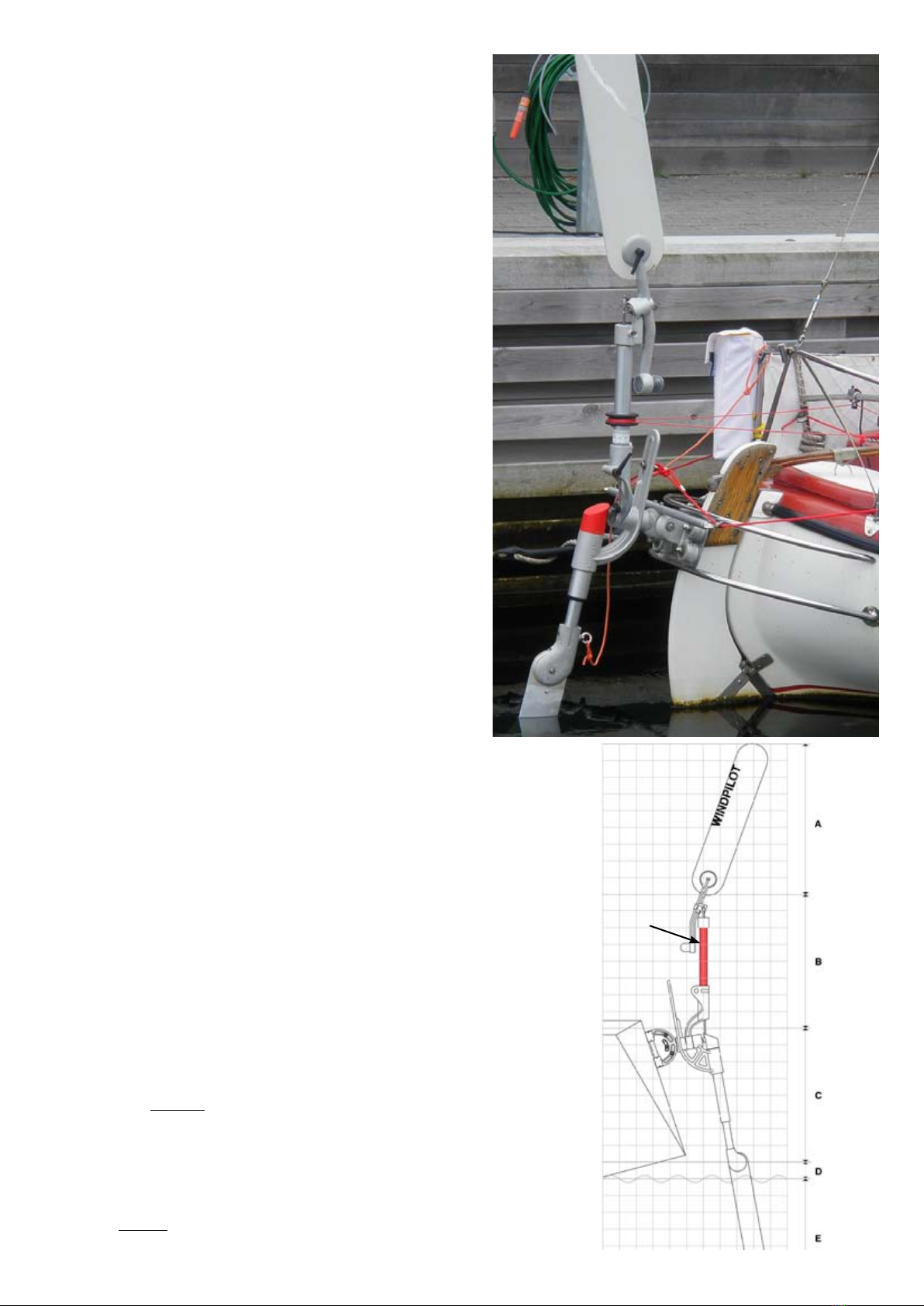

• Slidethesystemintothebracketwiththependulum

axle 310 at the front and fasten in place with

mounting bolt 901.

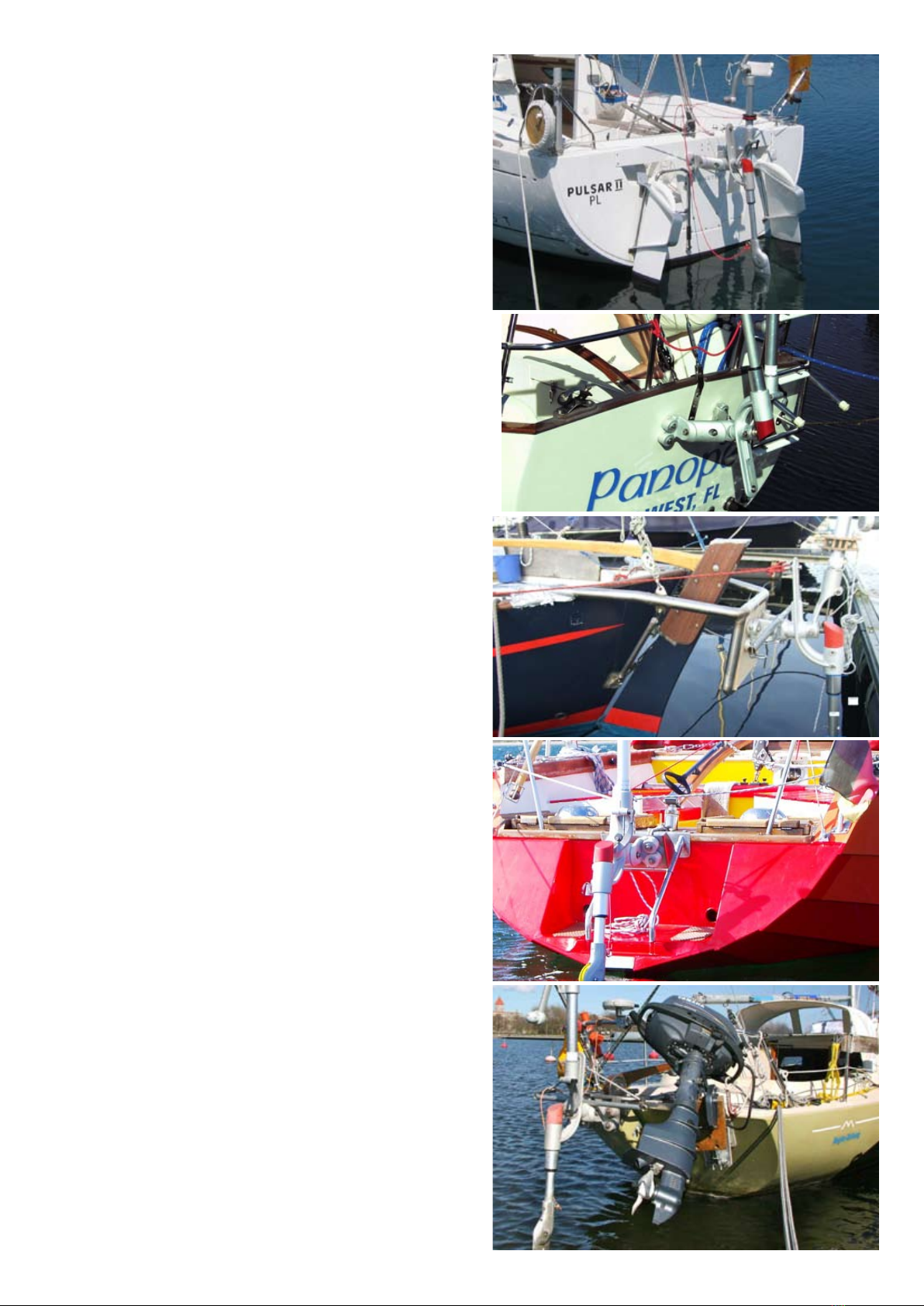

1.5.5 ALIGNMENT

WINDVANE SHAFT 140

• Thewindvaneshaft140mustbevertical.

• Side-to-sideadjustment:releasebolt701

• Fore-and-aftadjustment:releasebolt201

• Don’tforgettoretightentheboltsoncethe

windvane is properly aligned!

• Ifyoustillcan’tmakethewindvanevertical,see

1.5.4 What if the Bracket is Aligned Incorrectly?

1.5.6 PENDULUM RUDDER LIFT-UP

• Tieoneendoftheredlift-uplinethroughring431

and secure the other end to the pushpit. Raise the

pendulum rudder, take the red line once around

windvane shaft 140 and rudder shaft 400 and tie it

back to the pushpit.

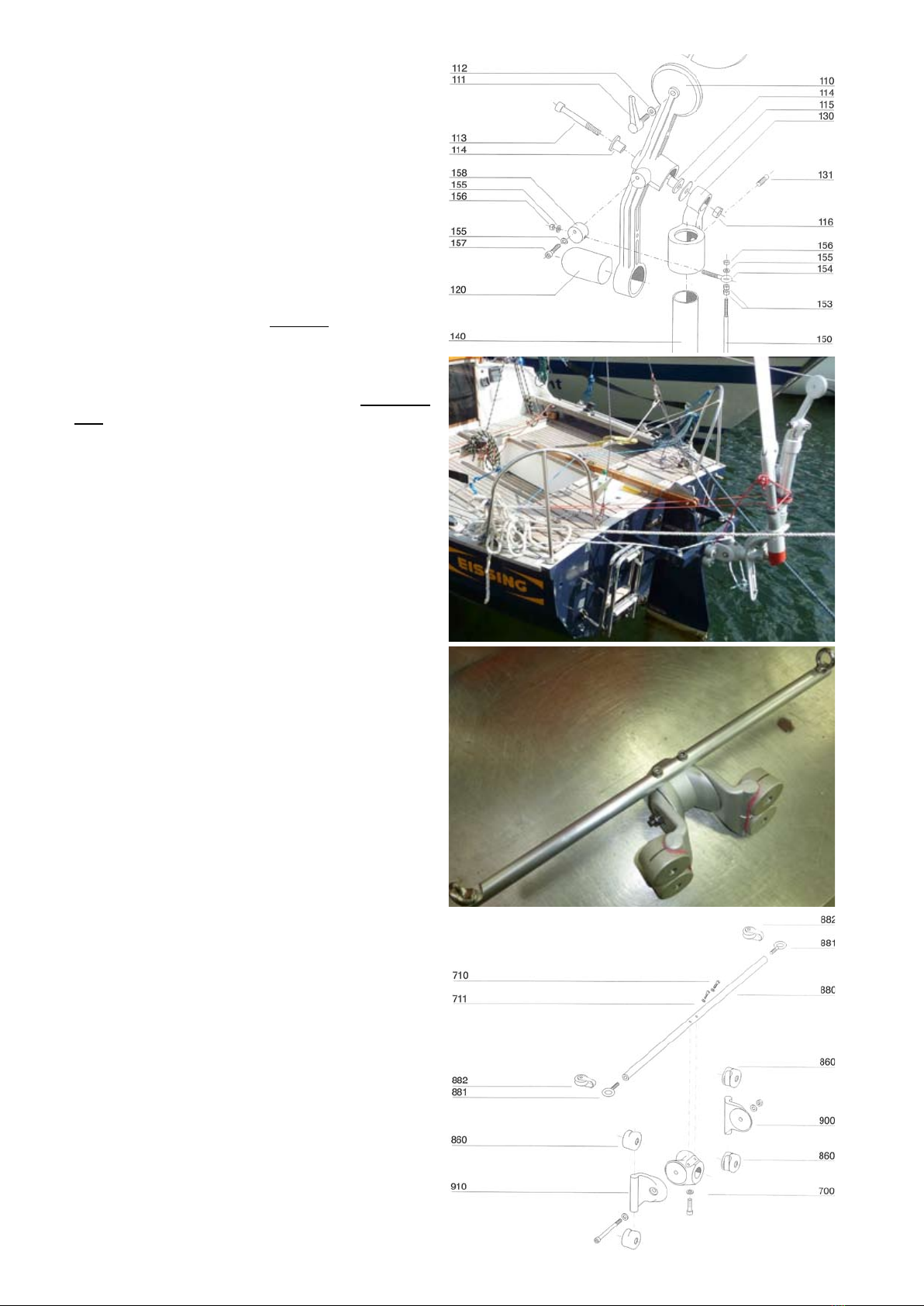

1.6 THE STEERING LINES

1.6.1 GENERAL

• ThesteeringperformanceofyourPACIFICLIGHT

will be strongly influenced by the quality of the

force transmission from the pendulum rudder to

the main rudder; in other words, you can’t have

good steering unless the steering lines are working

smoothly.

• Dependingonthesettingofthevariable

transmission, the PACIFIC LIGHT provides

maximum steering line travel of between 20 and

25 cm/8 and 10 in (a feature it shares with other

popular systems like the Aries and Monitor).

• Anythingthatimpairstheforcetransmissionwill

have an immediate impact on steering quality.

Slack, stretch or play in the steering lines or

stiffness in the main rudder bearings all detract

from the performance of your system. Errors and

compromises at this point add up to poor steering,

plain and simple. All servo-pendulum gears that use

the 2:1 bevel gear linkage (Aries, Fleming, Monitor)

work in exactly the same way. The differences lie in

the operating conditions on different boats!

• NOTE:whatuseis20-25cm/8-10inoftravelatthe

pendulum arm if only a fraction of that reaches the

main rudder?