Table of Contents

Why an Analysis Program? ........................................................................................................................2

Goals..........................................................................................................................................................2

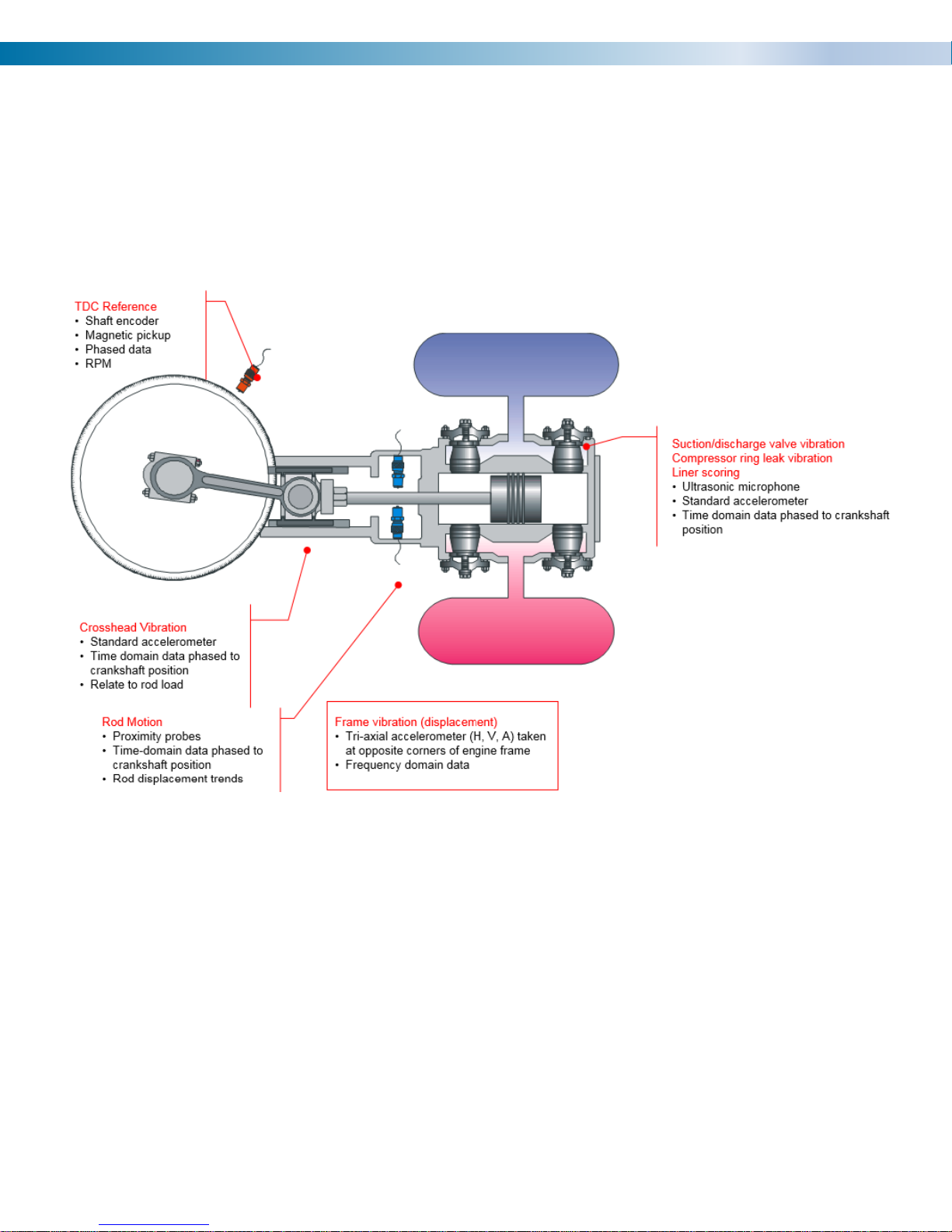

Engine Data Collection Locations...............................................................................................................3

Compressor Data Collection Locations.......................................................................................................4

Batteries and Charging...............................................................................................................................7

6400 Analyzer ............................................................................................................................................8

Adjusting Analyzer Screen Brightness......................................................................................................10

Adjusting Analyzer Date/Time ..................................................................................................................11

Encoder / Wireless Transmitter.................................................................................................................12

Encoder / Wireless Transmitter Functions ................................................................................................14

Selecting a Wireless Transmitter Channel................................................................................................20

Magnetic Pickup / Optical Sensor.............................................................................................................21

Cables......................................................................................................................................................22

Strobe (Timing) Light................................................................................................................................23

Engine Pressure Transducer....................................................................................................................24

Compressor Pressure Transducer............................................................................................................25

Pressure Transducer Calibration (Zeroing the Sensor).............................................................................26

Primary Ignition ........................................................................................................................................27

Secondary Ignition....................................................................................................................................28

Accelerometer..........................................................................................................................................29

Velocity Probe..........................................................................................................................................30

Ultrasonic / Infrared Temperature.............................................................................................................31

Ultrasonic Gain Adjustment......................................................................................................................32

Headphones.............................................................................................................................................34

/VA Kit Additional Items............................................................................................................................37