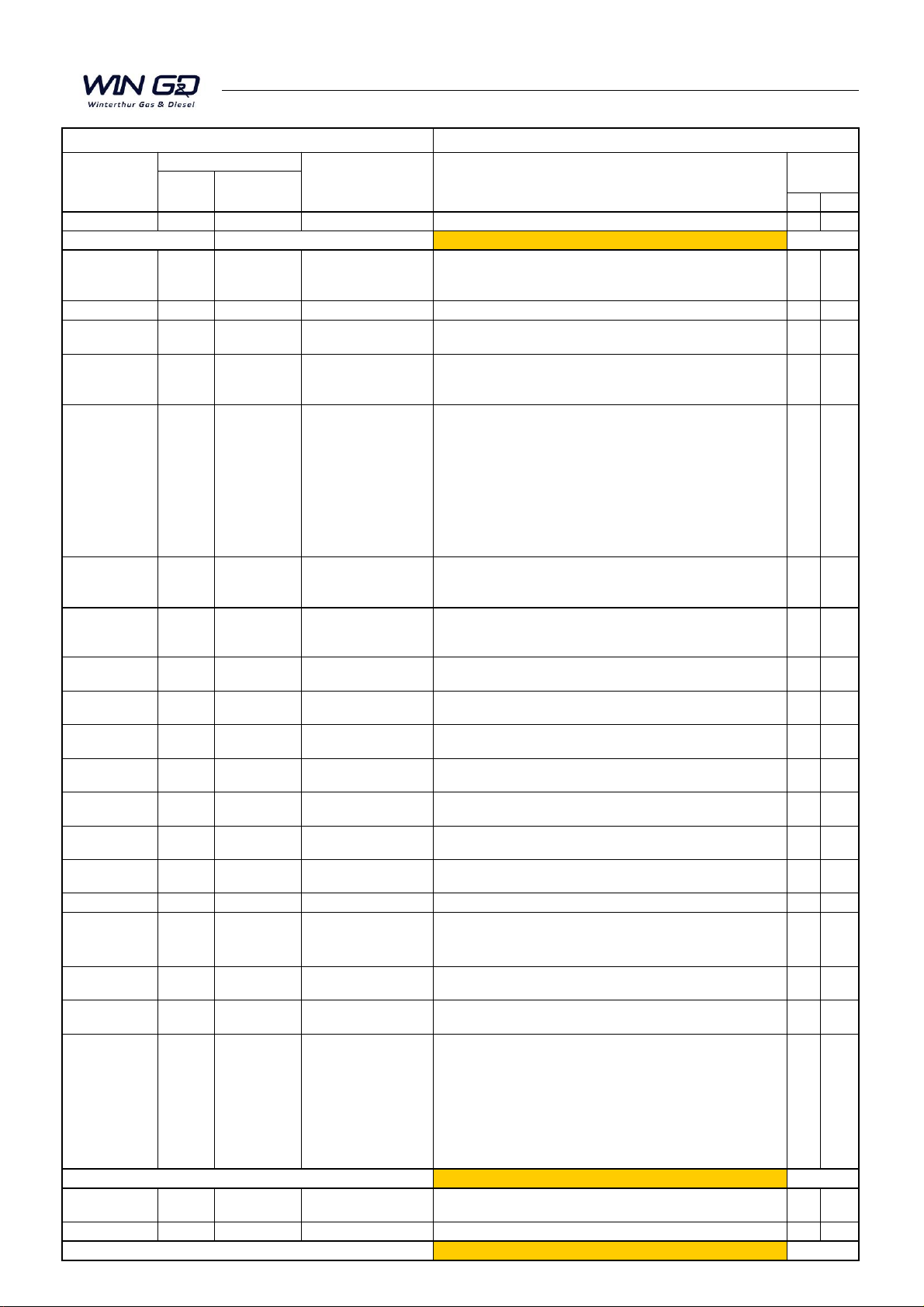

MaintenanceTOC

Table of Contents

RT-flex50DF

2016 2/ 4 Winterthur Gas & Diesel Ltd.

Engine Stays with Friction Shims: Tension −Checks 1715−1/A1......................................

Hydraulic Engine Stays: Oil Pressure Checks 1715−1/A2.............................................

Tie Rod: Tension Checks and Replacement Procedure 1903−1/A1.....................................

Cylinder Liner and Cylinder Cover Group 2

Cylinder Liner

Measure the Cylinder Liner 2124−1/A1...........................................................

Removal and Installation 2124−2/A1.............................................................

Remove Unwanted Material, Dress the Lubricating Grooves and Scavenge Ports 2124−3/A1............

Lubricating Quill: Removal and Installation 2138−1/A1...............................................

Gas Admission Valve GAV50: Removal, Disassemble, Checks, Assemble, Installation 2140−1/A1.......

Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation 2303−1/A1......

Cylinder Cover

Cylinder Cover and Water Guide Jacket −Removal and Installation 2708−1/A1........................

Cylinder Cover Elastic Studs −Loosen and Apply Tension 2708−2/A1................................

Machining of Sealing Face for Injection Valve 2708−3/A1............................................

Sealing Face for the Pilot Injection Valve Position −Grind 2708−4/A1................................

Sealing Face for the Fuel Injection Valve Position −Grind 2708−5/A1................................

Sealing Face for the Prechamber −Grind 2708−6/A1..............................................

Injection Valve: Removal and Installation 2722−1/A1.................................................

Injection Valve: Checks, Disassemble, Assemble 2722−2/A1.........................................

Injection Valve: Installation of Injection Valve with FAST 2722−1/A2...................................

Starting Air Valve: Removal, Disassemble, Grind, Assemble, Installation 2728−1/A1....................

Exhaust Valve

Removal and Installation of Exhaust Valve, Replacement of Elastic Studs 2751−1/A1...................

Disassemble and Assemble 2751−2/A1...........................................................

Replacing and Grinding the Valve Seat 2751−3/A1.................................................

Grinding the Seating Surface on the Valve Head 2751−4/A1.........................................

Pilot Injection Valve: Removal, Disassemble, Check, Assemble, Installation 2790−1/A1.................

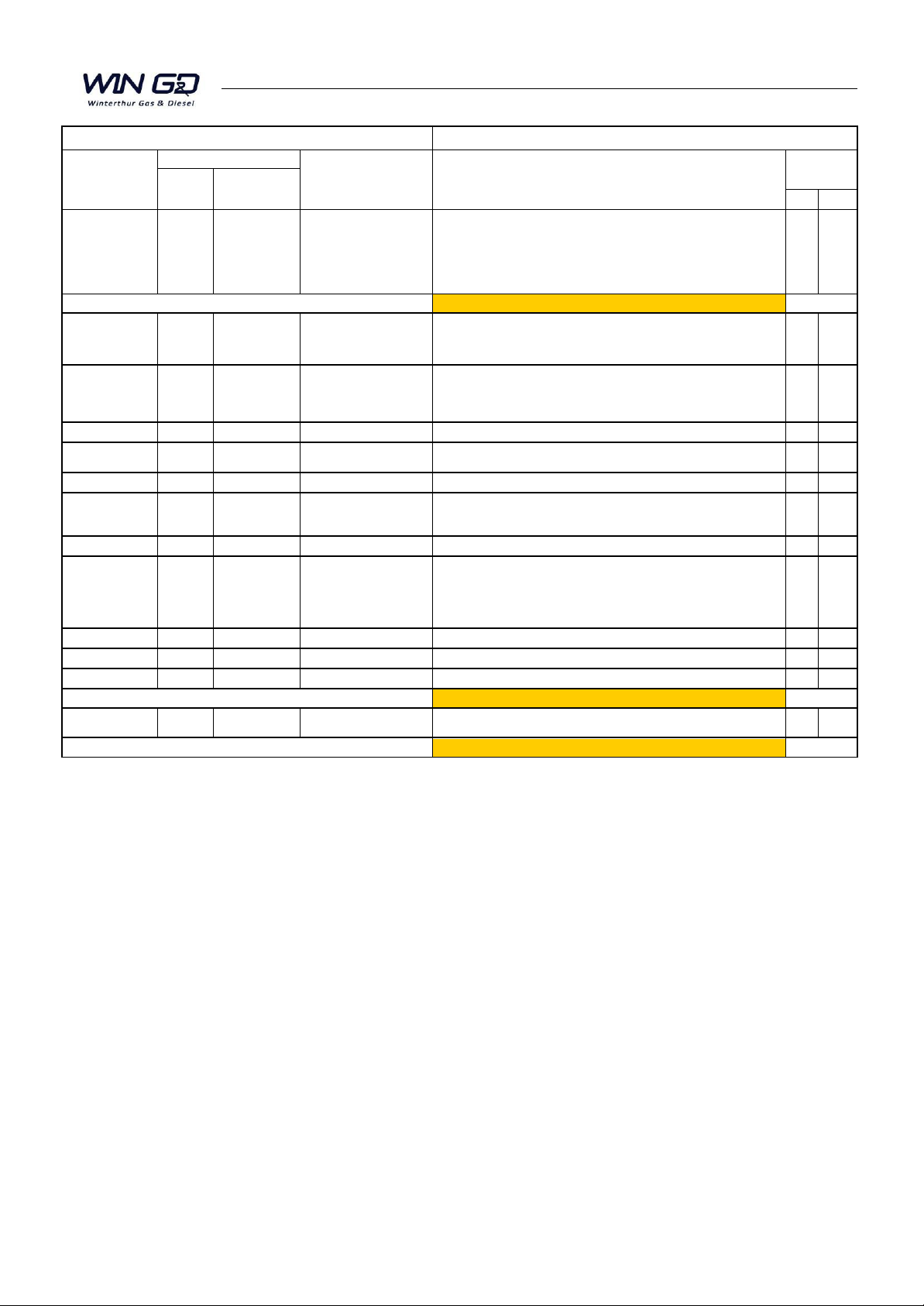

Crankshaft, Connecting Rod and Piston Group 3

Crankshaft: Crank Deflection −Measure 3103−1/A1.................................................

Vibration Damper

Inspection (GEISLINGER Vibration Damper) 3130−1/A1............................................

Axial Damper: Disassemble and Assemble 3140−1/A1................................................

Turning Gear: Teeth and Screwed Connections Check 3206−1/A1.....................................

Crankcase: Work Platform 3301−1/A1..............................................................

Top Platform: Configuration of Lifting Tools 3301−2/A2...............................................

Winterthur Gas & Diesel Ltd.RT−flex50DF / MM / 2020