4094-00 60708-162

3

INTRODUCTION AND

DESCRIPTION

PRODUCT DESCRIPTION:

This engine-generator set is designed for manual key start

operation. The engine-generator set is fully tested at the factory

prior to shipment to insure proper operation of each individual

component as well as the total system’s performance and

reliability.

The engine generator set consists of a multi-cylinder, liquid cooled

engine nominally operating at 1800 rpm. The generator frequency

regulation is maintained by the engine governor to within +/- 1.5

hertz (cps), from no load to rated load for standard mechanical

governors. The generator is a single bearing, direct drive, rotating

eld brushless design. The generator is connected to the engine

ywheel via exible drive disks. The Generator Set is skid

mounted with isolation mounts between the engine and base on

all units.

NOTICE:

These engine generator sets have only basic engine protections.

The Manual Key start panel only provides low oil pressure and

high coolant temperature protection, with no voltage or frequency

displays. The DSE 3110 electronic start panel displays a basic

voltage and frequency reading derived from a line to neutral

feed from the generator to the DSE 3110 control. Based on this

information it also provides basic over/under speed and voltage

protection. Low oil pressure and high water temperature reading/

shutdowns are provided by senders mounted on the engine. No

other control options are available on the DE Series Generators,

if you application requires additional safety devices or signals

consider upgrading to the DR Series Generators by WINPOWER.

A customer supplied 12 Volt battery is required to complete the

installation. Battery requirements are listed later under the battery

installation section.

These engine generator sets come standard with a manual key

start system. This key start system utilities a safety latching

relay that shut the unit down if the oil pressure gets low or water

temperature gets too high. The safety latching relay must be

depressed during cranking. Available as an option is a digital

DSE 3110 controller that is also programmed for electric start.

The DSE 3110 will electronically display your engine speed,

generator voltage, generator frequency, engine running time

and your battery level voltage. In addition it monitors your oil

pressure, water temperature, over/under speed and overcrank to

insure safe trouble free operation. Both systems are discussed

later in detail.

GENERATOR SET:

Every WINPOWER Generator Set has its own unique identity

data plate. This data plate identies the complete unit model

number, the system serial number and has links to the individual

components that form the generator set in our factory records.

Several of the major components also have their own individual

identity plates providing additional information to document build

data for warranty and replacement parts.

Be sure to have the main WINPOWER unit data plate information

recorded inside the front cover of this manual for future reference

and for identication whenever requesting eld or factory technical

assistance. Primary elds needed for assistance are complete

model number, serial number and especially the M-Spec number.

The M-Spec number (if provided) is recorded in the ‘TYPE NO.’

block on the lower right of the plate.

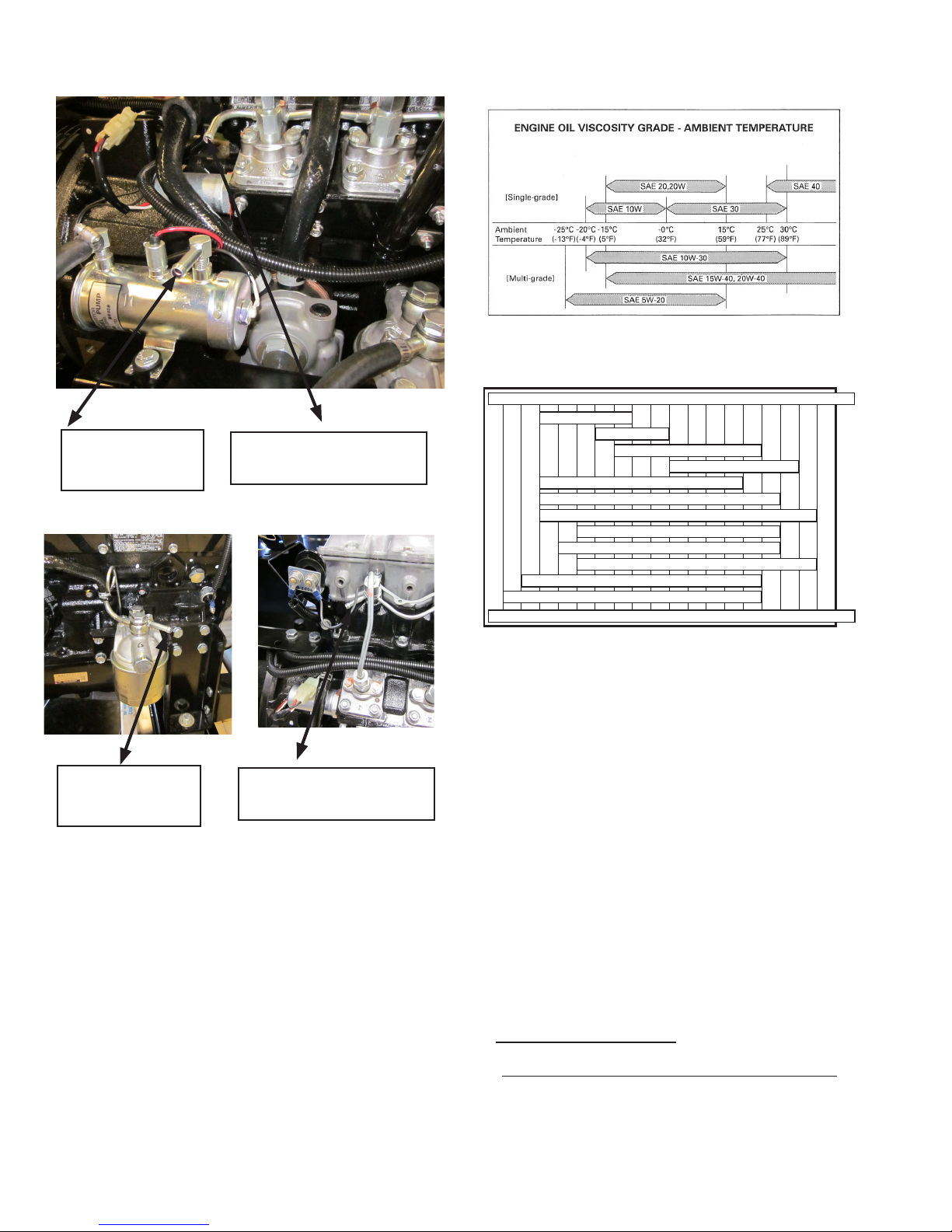

ENGINE:

This manual covers specic operation of the combined engine

generator set. Refer to engine operating and maintenance

instructions for specic instruction on the care and maintenance

of the engine. Oil and fuel requirements along with maintenance

schedules and engine warranty information are provided by the

individual engine manufacturers.

** CAUTION **

EQUIPMENT DAMAGE - Be sure to check the engine oil level

frequently as specied in the engine manual.

The engine manufacturer has established an excellent worldwide

engine service organization; engine service is available from a

nearby authorized dealer or distributor. Go to the WINCO web

site for a list of engine dealers. (http://www.wincogen.com/

Engine_Support/ )

The rated power of each engine-generator is limited by the

temperature, altitude and all other ambient conditions specied

by the engine manufacturer. Engine power will decrease 3-1/2%

for each 1000 ft. above sea level, and will decrease an additional

1% for each 10 degrees Fahrenheit above 60 degrees Fahrenheit.

Units should not be operated in ambient temperature greater than

125 degrees Fahrenheit.

GENERATOR:

WINPOWER Generator Sets use brushless, AVR (Auto-

Voltage Regulator) controlled broad-range generator ends. The

generator converts rotational mechanical energy into electrical

energy. These WINPOWER units are equipped with generators

manufactured by Cummins Stamford. Each generator ‘end’ has its

own data tag. A unique serial number is stamped on the data plate

and the data label is afxed to the main frame of the generator on

the left side.

RECEIVING THE GENERATOR

The generator set will generally be shipped by a commercial

‘common freight carrier’. Routing is determined by the bulk, size,

and a means available to unload the generator at the receiving

end. WINPOWER recommends units that are shipped by

common carrier be delivered to a commercial dock to allow the

Generator Set to be unloaded in a safe, efcient manner and to

minimize handling damage to the unit.

Locate the packing slip on the side of the crate or request it from

the truck driver. When receiving the generator take special care

in examining it for damage during shipment. Avoid signing for the

equipment until a full visual assessment and inventory have been

made. Verify that you have received the right equipment and the

proper amount by matching up the equipment to the packing list.