O e r a t i n g I n s t r u c t i o n s

OKTOPUS

®

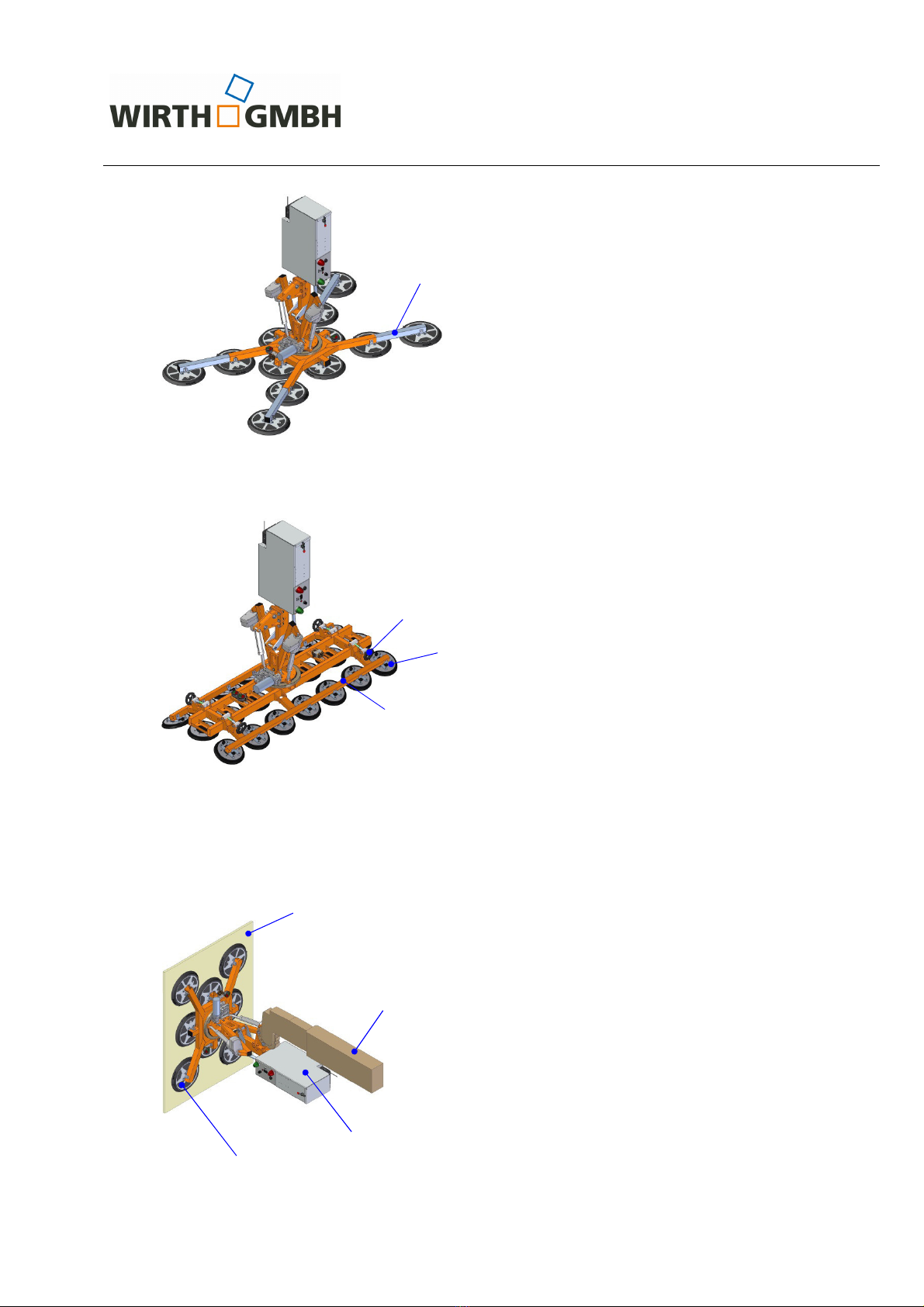

GL SS-Jack

GL-CC 1200

Technical Documentation

BA 000 257

Page 6 of 28

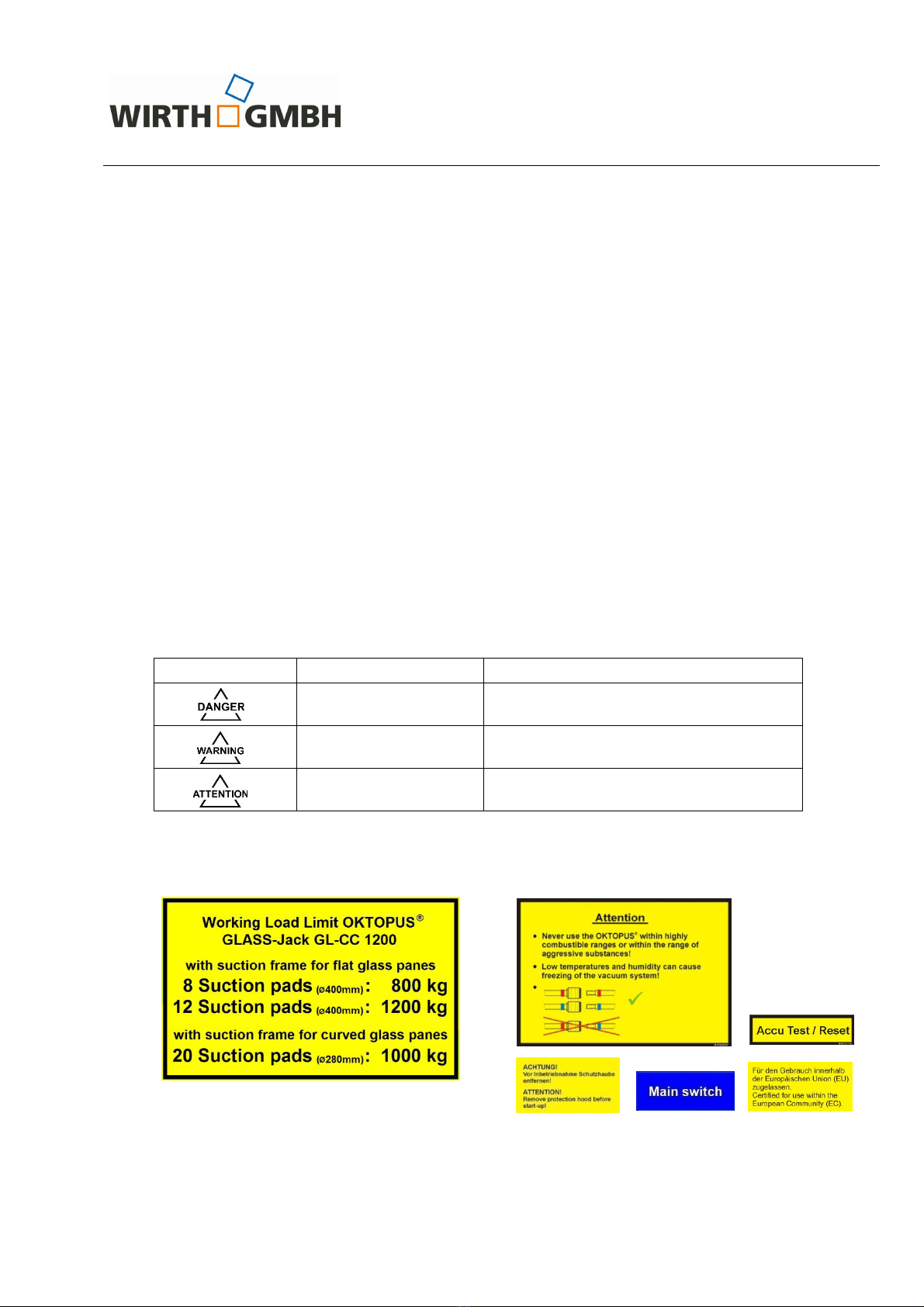

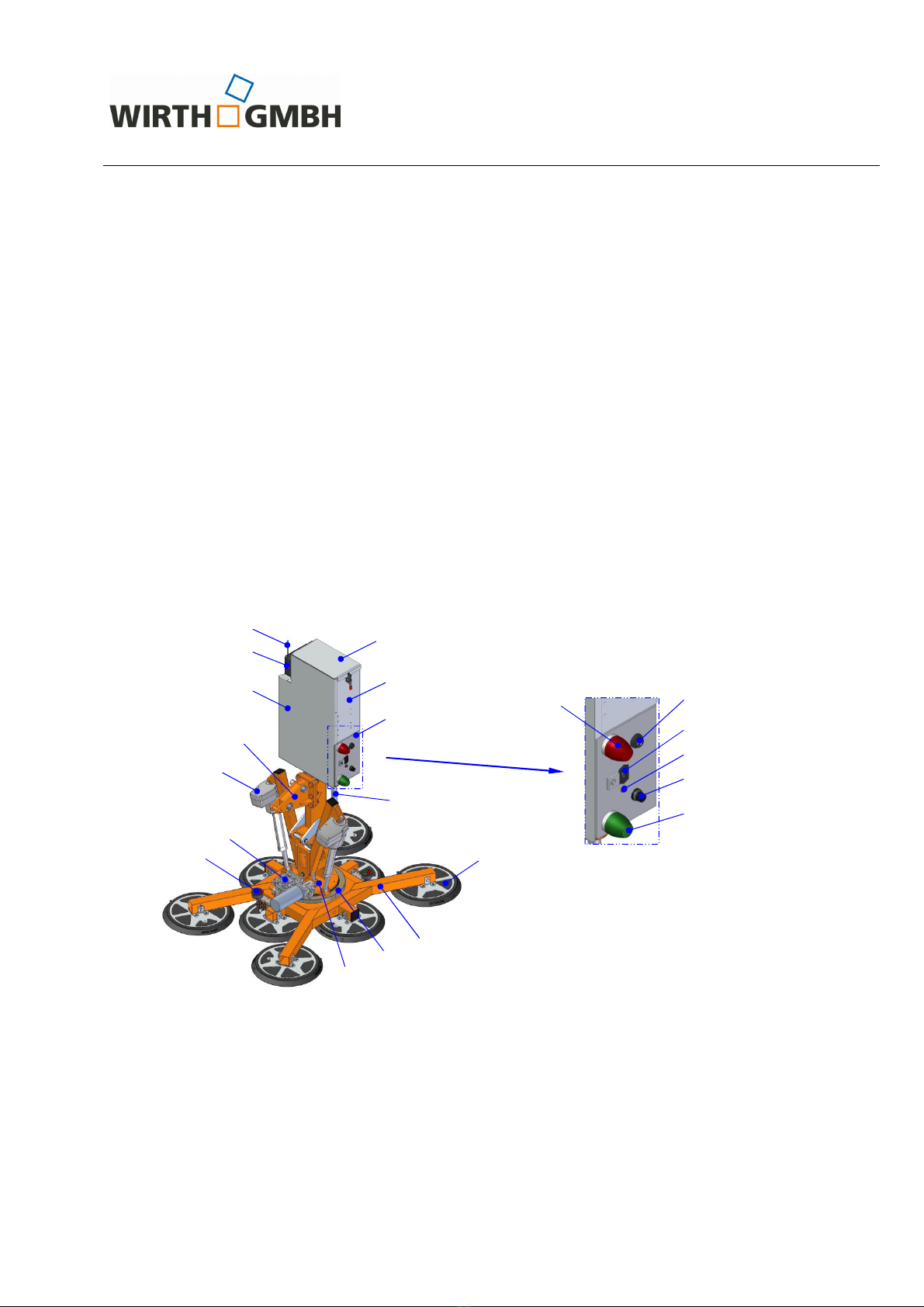

2.2 Safety instructions

(1) When selecting a crane, consider the influence of the dead-weight load and load ca-

acity of the OKTOPUS

®

GL SS-Jack GL-CC 1200, the wind and acceleration loads,

the intended and unintended load eccentricities on the Working Load Limit and/or the

stability of the crane as well as resulting reductions of the carrying ca acity diagrams of

the crane.

(2) Never use a damaged, not fully functional or not com lete OKTOPUS

®

!

(3) Prior to initial startu have an expert check and document the combination crane/

OKTOPUS

®

!

(4) Only o erate the crane with an operating license!

(5) Only o erate OKTOPUS

®

and minicrane if you are familiar with the control and dis-

play elements as well as the operating manuals. You have to know how the func-

tions affect the entire installation!

(6) Prior to using OKTOPUS

®

and crane check the function of the control and display

elements as well as the warning devices!

(7) Ensure that the crane o erator is able to overview the assembly and installation site!

(8) Agree on hand signals with the rigger or installer for the necessary crane movements!

(9) It is absolutely necessary to observe the maximum Working Load Limit of the OK-

TOPUS

®

GL SS-Jack GL-CC 1200 sti ulated in section 2.3 Symbols and markings!

These s ecifications only a ly to a working height corres onding 400 m above sea

level!

(10) If the suction ads are covered by protecting cowls, these have to be removed be-

fore startu !

(11) Only work at wind s eeds less than 30 km/h, otherwise you risk uncontrollable swing-

ing of the load!

(12) Check the suction rubbers daily for damages; if necessary re lace the suction rub-

bers by new ones.

(13) Clean the suction areas of the glass anes. Do not place the suction ads on pro-

tective film, releasing agents or similar, but remove it at least at the contact areas of

the suction ads.

(14) Never stand or walk under the suspended load!

(15) Make sure that nobody climbs the OKTOPUS

®

GLASS-Jack GL-CC 1200 or the sus-

ended load and tries to ride along.

(16) Stop working instantly if the alarm buzzer sounds and/or the red warning light is

illuminated! In this case the system is severely damaged and there is the risk that the

sucked load might dro . Carefully lower the OKTOPUS

®

together with the sucked load

with the hel of the crane until the load is securely laced. The cause of the alarm has

to be found and removed. In case of unrecoverable errors all o erations with the OK-

TOPUS

®

have to be discontinued immediately. The OKTOPUS

®

has to be secured

against further use.

(17) In case of incidents and maintenance work turn off the OKTOPUS

®

. Therefore, turn

the main switch to osition OFF!

(18) Never em loy the OKTOPUS

®

in explosive areas or in the area of aggressive me-

dia!

(19) Take into consideration that low temperatures and high humidity may cause freez-

ing of the vacuum system!

(20) Never attempt to lift damaged glass or façade elements!

(21) Do not lift the load higher than necessary!