Time Versalift SST-37-EIH User manual

Operator’s Manual

Time Manufacturing Co. 7601 Imperial Drive P.O. Box 20368 Waco, Texas 76702 Phone: 254-399-2100 Fax: 254-751-0775

Aerial Device

ATTENTION:

THIS MANUAL CONTAINS CONFIDENTIAL INFORMATION

AND IS THE SOLE PROPERTY OF TIME MANUFACTURING CO.

CONTENTS ARE NOT TO BE DISCLOSED, COPIED, OR REPRODUCED

IN ANY MANNER WITHOUT THE EXPRESSED, WRITTEN PERMISSION

OF TIME MANUFACTURING CO.

DO NOT ATTEMPT TO OPERATE THIS VERSALIFT UNTIL

YOU HAVE READ AND UNDERSTOOD ALL INFORMATION IN BOTH

OPERATOR’S AND SERVICE MANUALS, PROVIDED WITH EACH

VERSALIFT.

MANUAL PART NUMBER

28009-09

SERIAL NUMBER

SST-37/40-EIH

Time Manufacturing Co. reserves the right to improve the design or change specifications at any time without notice.

09/16

PLEASE NOTE THE ANSI A92.2 STANDARD AND THE MANUAL OF RESPONSIBILITIES CONTAINS

RECENTLY UPDATED INFORMATION. DEALERS, OWNERS, USERS, OPERATORS, LESSORS AND LESSEES MUST

ADHERE TO THESE UPDATED STANDARDS.

MANUFACTURING COMPANY

OWNER’S WARRANTY

The Versalift Aerial Platform Lift is engineered and designed to perform as stated on

published specifications. Only quality material and workmanship are used in the

manufacture of this product. With proper installation, regular maintenance, and periodic

repair service, the equipment will provide excellent service.

Those parts of the Versalift that are manufactured by Time Manufacturing Company

are warranted for one full year from date of purchase. Structural components will carry

a lifetime warranty for defects in material and workmanship which existed at the time of

initial delivery, wear components are not covered by this statement. This warranty is

issued only to the original purchaser and promises that Time Manufacturing Company

manufactured products are free from defects in material and factory workmanship

when properly installed, serviced, and operated under normal conditions, according to

the manufacturer’s instructions.

Manufacturer’s obligation under this warranty is limited to correcting without charge at

its factory any part or parts thereof which shall be returned to its factory or one of its

Authorized Service Stations, transportation charges prepaid, within one year after being

put into service by the original user, and which upon examination shall disclose to the

Manufacturer’s satisfaction to have been originally defective. Correction of such defects

by repair to, or supplying of replacements for defective parts, shall constitute fulfillment

of all obligations to original user.

This warranty shall not apply to any of the Manufacturer’s products which must be

replaced because of normal wear, which have been subject to misuses, negligence or

accident, or which shall have been repaired or altered outside of the Manufacturer’s

factory (unless authorized by the Manufacturer in writing), products which have not

been maintained and operated in accordance with Time Manufacturing Company’s

operators, maintenance manuals and bulletins, products which are repaired without

using original Time Manufacturing Company parts. This limited warranty does not

cover transportation fees and/or consumables used for the repair. Products or parts

manufactured by others are covered only by such warranties as are extended to TIME

MANUFACTURING CO. by its suppliers.

Manufacturer shall not be liable for loss, damage, or expense directly or indirectly from

the use of its product or from any cause.

The above warranty supersedes and is in lieu of all other warranties, expressed or

implied, and of all other liabilities or obligations on part of Manufacturer. No person,

agent, or dealer is authorized to give any warranties on behalf of the Manufacturer or to

assume for the Manufacturer any other liability in connection with any of its products

unless made in writing and signed by an officer of the Manufacturer.

28009-09 09/16VERSALIFT SST-37/40-EIH i

TABLE OF CONTENTS

TABLE OF CONTENTS

Introduction Section 1

Manual Structure ........................................................................................................................ 1-1

Additional Manual Features ........................................................................................................ 1-1

Nomenclature ............................................................................................................................. 1-2

Responsibilities / Safety Section 2

Responsibilities of Dealers, Owners, Users, Operators, Lessors and Lessees ......................... 2-1

Decals ......................................................................................................................................... 2-2

Think Safety ................................................................................................................................ 2-6

What is Insulated and What is not Insulated .............................................................................. 2-9

Additional Safety Considerations .............................................................................................. 2-10

Specifi cations Section 3

General Specifi cations ................................................................................................................ 3-1

Option Specifi cations .................................................................................................................. 3-2

Dimensional Specifi cations ......................................................................................................... 3-5

Vehicle Specifi cations ............................................................................................................... 3-11

Operation Section 4

Positioning the Versalift for Operation ....................................................................................... 4-1

Aerial Lift Operations .................................................................................................................. 4-2

Cab Control Operation ............................................................................................................... 4-4

Ground Control Operation ......................................................................................................... 4-4

Lower Control Operation ........................................................................................................... 4-6

Upper Control Operation ............................................................................................................ 4-6

Storing the Aerial Lift ................................................................................................................. 4-8

Lift Eye Operation (optional) ....................................................................................................... 4-9

Emergency Operation Section 5

Daily Visual Inspection Section 6

1-1 28009-09 09/16VERSALIFT SST-37/40-EIH

INTRODUCTION

DANGER: READ AND UNDERSTAND

THIS MANUAL BEFORE ATTEMPTING TO

OPERATE THIS AERIAL DEVICE.

The manual identifies all the controls and their

locations and describes how the controls function.

Routine preventive maintenance is very important in

maintaining reliable aerial lift service. A preventive

maintenance schedule is provided and must be

understood and followed by all operators.

DANGER: THIS IS NOT MAINTENANCE

FREE EQUIPMENT.

NOTICE: THIS MANUAL IS A PERMANENT

PART OF THE VERSALIFT AERIAL DEVICEAND

MUST REMAIN WITH THE UNIT ALWAYS.

Time Manufacturing Company reserves the right

to improve the design or specifi cations at any time

without any obligation to incorporate new features

into products previously sold.

MANUAL STRUCTURE

This manual is divided into six, numbered chapters.

The fi rst number in the page number at the bottom

of each page identifi es the chapter number. Chapter

tabs, with titles printed on them, allow easy location

of the desired subject.

ADDITIONAL MANUAL FEATURES

Danger, caution, and warning notes are indented,

bold faced, and separated from the regular text

to emphasize their importance and the need for

attention.

English measurements are followed by equivalent

metric measurements in parenthesis.

Non-critical units of measure are usually rounded-off

to the nearest whole unit.

Notes referring the reader to related information in

the manual indicate the chapter or a section of a

chapter, not to a single page. The reader may need

to scan a few pages to fi nd the needed information.

The Versalift aerial device has been designed and

engineered to conveniently place personnel at work

stations above the ground. This aerial device, as

manufactured, meets or exceeds all applicable ANSI

A92.2. Full controls at the platform and complete

freedom of boom movements make the Versalift a

truly fl exible and functional work platform.

NOTE: As the aerial device users, you must read,

understand, and follow the instructions in this

manual and other manuals supplied with this

aerial lift unit.

This manual is furnished to provide practical and

essential information for effi cient operation of the

Versalift aerial device. Proper operation of this aerial

lift is the responsibility of the operator and requires a

thorough understanding of its capabilities. Personnel

responsible for the operation of the aerial lift must be

familiar with and understand this manual.

In addition to, dealers, owners, operators, renters,

lessors and lessees are required to comply with the

requirements of the applicable section or sections

found in ANSI A92.2.

NOTE: For additional safety information

and required responsibilities, refer to the

accompanying EMI Safety Manual and Manual

of Responsibilities.

Detailed information for the maintenance inspection

and service of the Versalift aerial device can be

found in the accompanying Service Manual. Should

further installation information be required, contact

your local Versalift dealer or Time Manufacturing

Company.

DANGER: THIS EQUIPMENT SHOULD

BE OPERATED AND SERVICED ONLY BY

COMPETENT PERSONNEL FAMILIAR WITH

GOODSAFETYPRACTICES. THISINSTRUCTION

IS WRITTEN FOR SUCH PERSONNEL AND

IS NOT INTENDED AS A SUBSTITUTE FOR

ADEQUATE TRAINING AND EXPERIENCE

IN SAFE PROCEDURES FOR THIS TYPE OF

EQUIPMENT.

INTRODUCTION

THIS MANUAL CONTAINS CONFIDENTIAL

INFORMATION AND IS SOLE PROPERTY OF

TIME MANUFACTURING, AND IS NOT TO BE

DISCLOSED, COPIED, OR REPRODUCED

WITHOUT EXPRESSED PERMISSION OF

TIME MANUFACTURING.

1-2 28009-09 09/16VERSALIFT SST-37/40-EIH

INTRODUCTION

2-1 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

DANGER: FAILURE TO COMPLY WITH

YOUR REQUIRED RESPONSIBILITIES IN THE

USE AND OPERATION OF THE AERIAL DEVICE

COULDRESULTINDEATH ORSERIOUSINJURY.

IMPORTANT

You are required by ANSI/SIA A92.2 to read and

understand YOUR RESPONSIBILITIES before

you use or operate the Aerial Device. It is your

responsibility and your employer’s responsibility to

identify and comply with applicable codes, standards,

and regulations.

The operation of any aerial device is subject to

certain HAZARDS that can be protected against

only by the exercise of INTELLIGENCE, CARE

AND COMMON SENSE. It is essential to have

COMPETENT, CAREFUL PERSONNEL, TRAINED

in the INTENDED USE, SAFE OPERATION,

MAINTENANCE AND SERVICE of this type of

equipment.

The USER and OPERATOR MUST MAKE

DECISIONS on the maintenance, use and operation

of the Aerial Device with due consideration for the

fact that the SAFETY OF THE OPERATOR AND

OTHER PERSONNEL is dependent on those

decisions. FAILURE TO COMPLY with your

REQUIRED RESPONSIBILITIES in the use and

operation of the Aerial Device could result in DEATH

OR SERIOUS INJURY.

DANGER: READAND UNDERSTAND THIS

MANUAL BEFORE ATTEMPTING TO OPERATE

THIS AERIAL DEVICE.

RESPONSIBILITIES

(for Dealers, Owners, Users, Operator, Lessors and Lessees)

2-2 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

Only properly trained operators are qualified to

operate the Versalift aerial lift. Operator training

shall include complete instruction and understanding

of the manufacturer’s manuals, employer’s work

rules, and all related governmental regulations. Prior

to operation from the platform the machine must

be operating properly, must have been installed

properly, inspected, and maintained in accordance

with the manufacturer’s instructions. All safety signs,

guards, and covers must be in place and in proper

condition.

DANGER: ANUNTRAINEDORCARELESS

OPERATOR SUBJECTS HIM/HERSELF AND

OTHERS TO DEATH OR SERIOUS INJURY.

Throughout this manual there are danger, warning,

and caution notes that emphasize the possible

hazards when operating the Versalift. It is the

responsibility of the operator to become familiar with

the contents of this manual.

Two of the main risks associated with operating an

aerial lift:

(1) Electrocution caused by operating too close

to power lines.

(2) Injuries caused by falling as a result of

equipment failure or the operator performing

an unsafe or unstable maneuver.

No manual can address every conceivable operating

hazard. Therefore, the prevention of accidents

is greatly dependent upon good judgement and

common sense of the operator.

It is the responsibility of the operator to use the

Versalift only when it has been installed and

maintained in accordance with the manufacturer’s

manuals. The preventive maintenance program

outlined in this manual and the Service manual must

be followed.

It is extremely important for the operator to be

thoroughly familiar with the Versalift aerial device.

Study the information in this manual and the Versalift

controls until both are completely mastered. Then go

to a large, open area to practice using the aerial lift.

Decals are installed at numerous locations on the

aerial lift to warn personnel of the potential hazards

during the use and operation of the aerial lift. It is

important that the operator and ground personnel

read and understand the information on the decals.

If any decals are defaced, illegible or lost, they

must be replaced. Refer to the “Decal Placement”

illustration in this manual for a complete listing and

the locations of the decals. For your convenience

these decals are pictured on the following pages as a

quick reference for reviewing safety concerns and for

providing part numbers when ordering replacements.

DECALS

All the warning and instruction decals, and their

respective part numbers, on the Versalift aerial

device are included below and on the following

pages. The decals are not shown at actual size.

SAFETY

2-3 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

2-4 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

2-5 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

2-6 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

A safe attitude is very important to you, the operator.

Practice anticipating accidents and operating

hazards. Then determine a corrective course of

action to respond to the situa tion. This habit will

sharpen your safety awareness, quicken your

reaction time, and prevent many accidents.

THINK SAFETY

The following sketches illustrate some of the

unsafe situations that might occur during the use

or operation of the Versalift. Some of these safety

problems are very basic and as a result are often

taken for granted.

Always engage the outriggers, and maintain the

correct tire pressure to increase vehicle stability.

Always wear a personnel restraint systemattached

to the lanyard anchor.

Don’t park the truck on a hill unless absolutely

necessary. When the truck is parked on a slope,

take the special precautions defi ned in Chapter

4, “Operation”.

Remember to set the parking brake and chock

the truck’s wheels.

Watch the booms to make sure they clear the

truck and other obstructions.

2-7 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

Maintain safe clearances from electrical power

lines and apparatus. The aerial lift does not

provide protection from contact or proximity to

an electrically charged conductors and another

conductor.

Never allow anyone on the ground to touch the

unit when the lift is being used to work on or

near electrical lines.

Never use the VERSALIFT as a crane

Stow the booms securely before moving the

truck.

Whenever tools or equipment are included with

the operator in the platform the combined weight

must not exceed the rated load capacity.

Avoid dropping tools. Use a hand line to raise

or lower tools to/from the platform.

2-8 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

Stand only on the platform fl oor.

Don’t climb out of a raised platform onto poles,

etc.

Keep the fiberglass booms clean and dry.

Foreign substances on the booms conduct

electricity.

2-9 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

What Is Insulated and What Is Not Insulated

Articulated/Telescopic and Articulated Models

Area 1, Boom Tip Area – The boom tip area does

not provide insulation. This area includes everything

past the insulated section decal* on the upper boom.

This includes the upper end of the boom, platform

support, platform(s), controls, and the jib/winch/rope

(when so equipped).

All components at the boom tip area must be

considered to be conductive and electrically

connected, even with an insulated liner in place.

Any contact with a ground and a phase or between

two phase conductors will create a hazard of serious

personal injury or death. Contact between an

energized conductor and any part of the boom tip

will energize the entire boom tip.

When working near an energized conductor, ground

conductor, or other grounded objects, the operator

must use the proper safety equipment (such as

rubber gloves, covers, hot sticks, etc.), maintain

safe approach distances, and follow company work

practices.

Area 2, Upper Boom Insulation Section – This

section provides insulation** between the boom

tip area and earth ground when clean and properly

maintained. On some confi gurations, it is necessary

to extend the boom until the insulated section decal

is visible.

Area 3, Intermediate Structure – This section

does not provide insulation. This area includes

the lower steel portion of the upper boom, knuckle,

and the steel upper portion of the lower boom and

compensation link (when applicable).

Area 4, Lower Boom Insulating Section – (When

so equipped) This section provides insulation**

between the intermediate structure (Area 3) and

the vehicle when clean and properly maintained.

Area 5, Lower Structure – This area does not

provide insulation. This area includes the steel lower

portion of the lower boom and compensation link

(when applicable), turret, lower controls, pedestal,

and the vehicle.

* On VST and T-Series models not supplied with an

upper insulated section decal, the insulated section

begins 11 inches below the center of the platform

pivot.

** Insulation properties are defi ned by ANSI A92.2

2-10 28009-09 09/16VERSALIFT SST-37/40-EIH

RESPONSIBILITIES / SAFETY

ADDITIONAL SAFETY CONSIDERATIONS

1. Report any unusual occurrence during the

operation of the aerial lift that may require

repair or adjustment.

2. Keep the work space in the truck bed clean

and neat.

3. Avoid parking on soft surfaces. Soft surfaces

may suddenly collapse, shift, or sink beneath

the truck’s weight.

4. There is no insulating value in the fi berglass

platform without a platform liner.

5. No attempt should be made to clean, oil,

or adjust a machine while the machine is in

motion.

6. If an aerial lift has set idle for an extended

period (i.e. overnight) or has been recently

serviced, cycle the aerial-lift through it’s full

range of motion several times. This procedure

will force any trapped air out of the hydraulic

system. Do not operate the lift from the platform

until this process is completed. Air trapped in

the hydraulic oil can cause lift movements to

be erratic and unpredictable.

7. Don’t operate any part of the unit (platform,

booms, outriggers, etc.) outside the work-

site barricades into the traffi c lanes. Set up

adequate cones or barricades to mark the

boundaries of the work-site to alert motorists

and pedestrians.

8. Only qualifi ed mechanics are authorized to

service the aerial lift.

9. Avoid contacting a spray mist produced by

a high pressure hydraulic leak. This spray

or mist can puncture or become embedded

beneath the skin or contaminate the eyes.

These conditions require immediate medical

attention.

10. Hydraulic oil is fl ammable. Avoid any contact

between hydraulic oil and sources of high heat

or open fl ames.

11. Bodily contact with hot hydraulic oil can cause

serious burns which require immediate medical

attention.

3-1 28009-09 09/16VERSALIFT SST-37/40-EIH

SPECIFICATIONS

SST-EIH GENERAL SPECIFICATIONS

Note: Specifications on units may vary or change

without prior notifications due to option selections.

This section includes a brief description of each of

the major (standard) components.

PLATFORM - The fi berglass platform is 24 in. x 24

in. x 42 in. (0.61 m x 0.61 m x 1.07 m) deep with

an inside and outside step for easy access. The

platform capacity is 300 lbs. (136 kg).

SINGLE STICK PLATFORM CONTROL - The

Unitrol single-stick control consists of a multi-jointed

handle which operates the control valve. A safety

trigger located on the underside of the single stick

handle will not allow boom movement until it is

depressed. The control valve is full pressure and full

fl ow. The operator can feather between the three

control movements to provide multi-function boom

action. An emergency stop control is provided.

INDIVIDUAL LOWER CONTROLS - Individual

full-pressure controls at the turret actuate all boom

functions. The lower control station is equipped with

a selector valve to override the upper controls.

HYDRAULIC PLATFORM LEVELING - Platform

leveling is controlled by a master and slave cylinder

arrangement. The platform leveling system can be

activated from the upper controls to adjust platform

leveling, tilt the platform for cleaning, or to ease the

removal of an injured operator.

PERSONNEL RESTRAINT SYSTEM - A safety

belt or harness and a lanyard are required and can

be supplied by Time Manufacturing Company at an

additional cost. Consult applicable work practices

and regulations to choose between a safety belt and

a harness. The anchor for the lanyard is attached

to the upper platform support.

OUTER/INNER BOOM ASSEMBLY- The outer/inner

boom assembly includes an outer boom, telescopic

inner boom, extension system, and hose assemblies.

The outer boom consists of a 6 in. x 8 in. (150 mm

x 200 mm) steel section and a 7.5 in. x 9.5 in. (190

mm x 240 mm) fi berglass section (Electroguard)

that maintains a 42 in. (1.08 m) insulation gap with

the inner boom fully retracted. The 5 in. x 7 in. (130

mm x 180 mm) rectangular fi berglass inner boom

is housed within the outer boom. The extension

system consists of a hydraulic cylinder, two holding

valves, and a hose carrier housed entirely within the

boom assembly. The hoses routed through the outer/

inner boom assembly are non-conductive and fully

contained within the boom assembly.

The outer/inner boom assembly articulates from 14°

below horizontal to 74° above horizontal. Actuated

by a double acting cylinder with a holding valve,

the outer/inner boom assembly is off set to one side

to provide easy access to the platform. A molded

rubber boom-support cradle supports the boom

when stowed, without the need for a tie-down strap.

COMPENSATED LOWER BOOM - The lower boom

consists of a 6 in. (150 mm) square steel section.

A double acting cylinder with dual holding valves

allows the SST-37 lower boom to articulate from

7° below horizontal to vertical for a total travel of

97°. The SST-40 lower boom articulates from 5°

below horizontal to vertical for a total travel of 95°.

A compensation link forms a parallelogram linkage

to maintain the outer/inner boom assembly at a

constant angle to the turret.

PINS - Pins are high-strength alloy steel which

are chrome plated for a hard fi nish and corrosion

resistance. Pins are bolted in place with a welded

pin tab at one end and a pin cap at the other for

redundant retention.

CYLINDERS - Both the outer and lower boom

cylinders are a threaded end-cap design. The

lower boom and extension cylinders are equipped

with two holding valves to prevent down creep and

to lock the booms in position in the event of hose

failure. The outer boom cylinder is equipped with

one holding valve.

TURRET - The turret wings are 1/2 in. (13 mm)

thick steel plate. A steel tube is welded between

the turret wings to support the boom cylinder and

provide rigidity. The turret plate is machined fl at

to support the rotation bearing. A bearing cover is

provided to prevent foreign material from interfering

with lift rotation.

ROTATION - Rotation is 370°, non-continuous with a

mechanical stop. Continuous, unrestricted rotation

is available as an option (see option descriptions).

Rotation is accomplished by a hydraulically driven

worm and spur gear set acting on a shear-ball

rotation bearing. The critical bolts holding the

turret to the rotation bearing and the bearing to the

pedestal are grade 8 hex head cap screws. These

critical bolts are marked with a torque seal indicator

to provide a quick means to inspect for relative

movement. A slotted adjustment is provided for

pinion and rotation gear clearances. An external

hex drive is provided for manual rotation in case of

hydraulic failure.

SPECIFICATIONS

3-2 28009-09 09/16VERSALIFT SST-37/40-EIH

SPECIFICATIONS

PEDESTAL - The pedestal is a round shape with an

access opening on both sides. The 12 gallon (45 l)

hydraulic reservoir is built integral to the pedestal. A

100-mesh suction screen and 10-micron return line

fi lter are located inside the pedestal. The top plate is

1-1/4 in. (32 mm) thick and machined fl at to support

the rotation bearing.

LUBRICATION - Non-lube bearings are used at all

points of motion. The rotation bearing is the only

component that requires periodic lubrication.

PAINTING - The complete unit is primed and painted

prior to assembly. The standard color is white

urethane.

HYDRAULIC OIL RESERVOIR - Designed as an

integral part of the pedestal, the reservoir has an

anti-splash baffl e and easy to read fl uid level gages.

The oil capacity of the reservoir is 12 gallons (45 l),

which is suffi cient for a 5 GPM (19 lpm) hydraulic

tool circuit.

HYDRAULIC SYSTEM - The open-center hydraulic

system operates at 3 gpm (11.4 lpm) at 2250 psi

(158 kg/cm2). The pump draws oil through a 100-

mesh suction screen. A 10-micron return line fi lter

with bypass valve is included. Fluid level gages are

furnished for checking fl uid level. Hydraulic oil is not

included. This system can be driven by the chassis-

engine accessory belt or by the chassis transmission

power-take-off .

HOSES AND FITTINGS - The hoses routed through

the booms are high pressure and non-conductive with

swaged hose end fi ttings. Nylon sleeves are installed

over hoses at points of movement. Reusable fi ttings

can be installed if a hose is damaged.

ENGINE START/STOP AND MASTER CONTROL

- The start/stop circuit has been designed so that

the lift cannot be operated unless the truck ignition

key is in the “run” position and the master switch is

“on.” This feature makes it diffi cult for unauthorized

individuals to operate the lift when the truck is locked.

An air cylinder at the platform and a toggle switch at

the turret are provided to actuate the engine start/

stop control.

ELECTRICAL INSULATION SPECIFICATIONS

- The outer/inner boom assembly is tested and

certifi ed for electrical work at 46 KV and below in

accordance with ANSI A92.2 requirements. Aerial

devices may be designed and confi gured for gloving

work and tool methods at 46KV and below. The

outer/inner boom assembly is fully insulated even

in a retracted position.

OUTRIGGER BOOM INTERLOCK SYSTEM -

The outrigger/boom interlock system is a feature

designed to prevent the lift from being operated until

the outriggers contact the ground. The interlock also

prevents the outriggers from being retracted before

the lower boom is properly stored.

SLOPE INDICATORS – Slope indicators are

required on Versalift units and supplied by Time

Manufacturing Co. Slope indicators shall be installed

to indicate the level of rotation bearing relative to

the ground.

MANUALS - Two Operator’s Manuals and two

Service Manuals, one Manual of Responsibilities

and one EMI Safety Manual are included with each

aerial lift.

SST-EIH OPTION SPECIFICATIONS

Below is a brief description of some of the available

options for the aerial lift.

INDEPENDENT H-FRAME OUTRIGGERS-

Outriggers are shear-plate mounted to the frame

and are equipped with pilot operated check valves,

internal thermal relief valves and separate controls.

The outriggers furnish 90 1/2 in. (2.3 m) of spread

and a maximum of 9 in. (.23 m) of penetration with

15 in. (.38 m) of ground clearance. Outrigger legs

are shipped loose to accommodate various frame

heights and body widths. Outrigger pivot feet are

standard.

INDEPENDENT A-FRAME OUTRIGGERS-

Outriggers are shear-plate mounted to the frame

and are equipped with pilot operated check valves,

internal thermal relief valves and separate controls.

At maximum extension, the outriggers furnish 125

3/4 in. (3.19 m) of spread and 9 in. (229 mm) of

penetration. They have 17 in. (432 mm) of ground

clearance based on 36 in. (0.91 m) or 31 in. (0.79

m) frame height. Outrigger pivot feet are standard.

TORSION BAR - Over frame and under frame

torsion bars are available and add to the stability

of the vehicle. All Stable Ride torsion bars include

rubber bushings at all points of movement and do

not require lubrication. Ballast may be required with

the use of torsion bars.

TALLER AND SHORTER PEDESTALS - Pedestals

6 in. (152 mm) taller or 6 in. (152 mm) shorter are

available.

CONTINUOUS ROTATION - Rotation is continuous

This manual suits for next models

1

Table of contents

Other Time Lifting System manuals

Popular Lifting System manuals by other brands

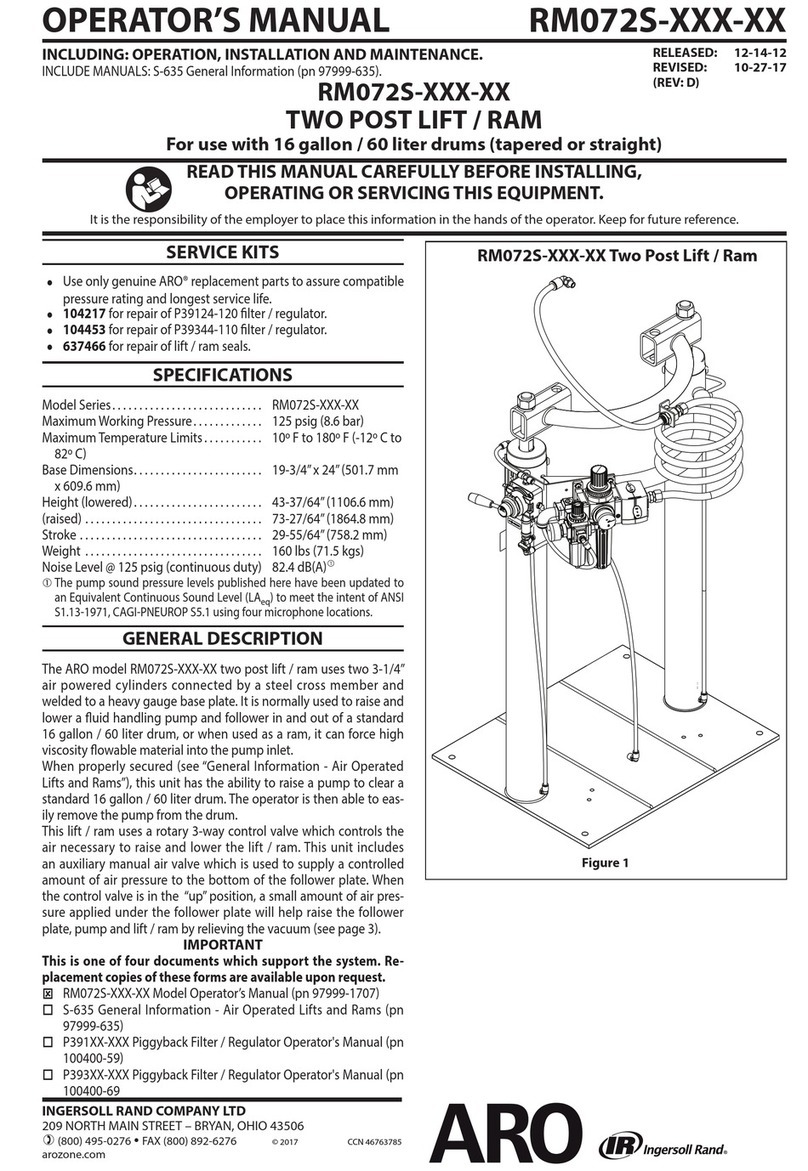

Ingersoll-Rand

Ingersoll-Rand ARO RM072S Series Operator's manual

Guldmann

Guldmann Stepless Pro 30046-100 user manual

Duarib

Duarib Altitude 150 Assembly, Disassembly and Use Instructions

Huskee

Huskee HZR350 manual

Harmar Mobility

Harmar Mobility AL030 Installation & owner's manual

Genie

Genie Z-45/25 Service and repair manual

MIR

MIR 500 EU Pallet Lift quick start

harbor master

harbor master Premier Verical Lift instructions

Haklift

Haklift VAK3SUPER Translation of the original instructions

Reese Explore

Reese Explore 7452700 owner's manual

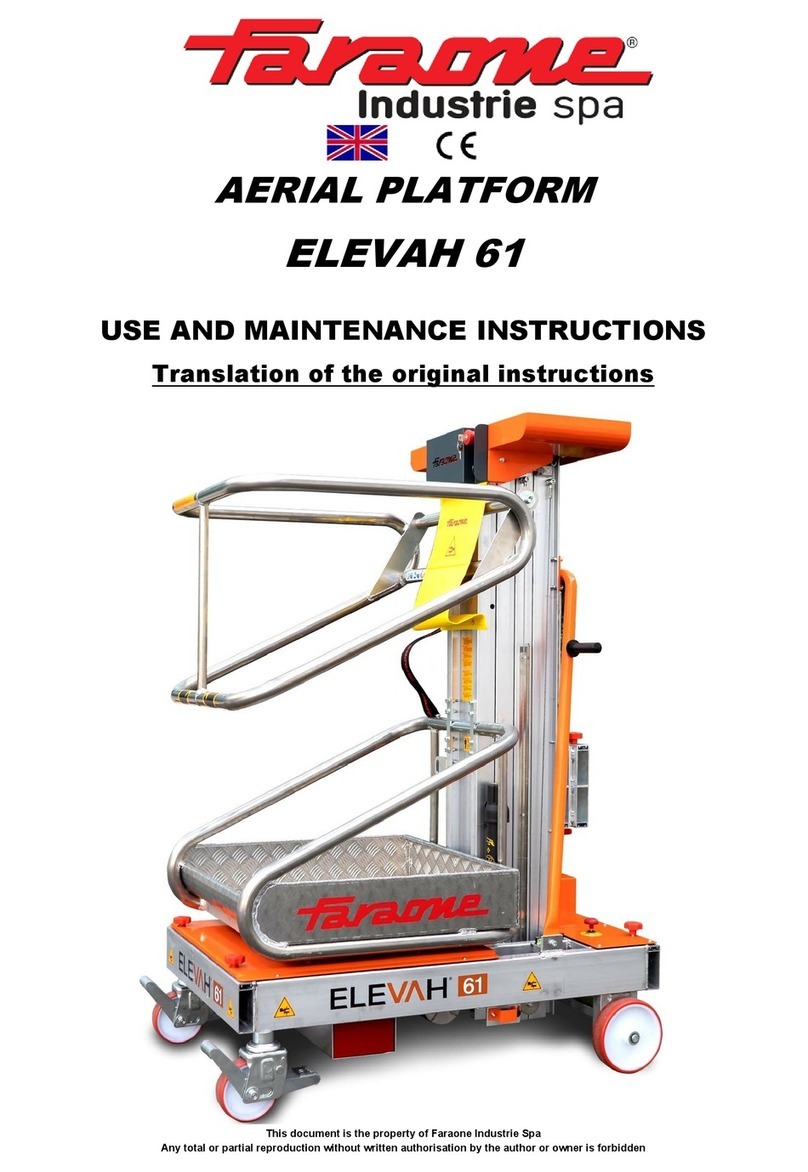

Faraone

Faraone ELEVAH 61 Translation of the original instructions

Tractel

Tractel KS USER OPERATING AND INSPECTION MANUAL