User Manual

2021 Release 2

WiseAir Technologies India LLP

support@wiseair.asia +91 90477 78715

Page 3 of 24

MEASURE TO MANAGE

Section 1 : General Information :

1.1 Please read this user manual in full and carefully observe the notes and

instructions before and during installation, operation and maintenance. The manufacturer

cannot be held liable for any damage which occurs as a result of non-observance or

noncompliance with this user manual.

Should the device be tampered with in any manner other than a procedure which is

described and specified in this manual, the warranty is cancelled and the manufacturer is

exempt from liability. The device is designed exclusively for the described application.

This user manual should be read carefully by the technician / qualified personnel and

the end user. Once you install, use or maintain this product, you accept that you have read,

understood and complied with this manual. This manual should be kept with the Flow Meter and

made available to relevant personnel as needed. WiseAir Endeavours to make changes to the

content of this Manual, and tries to ensure Correctness and well stated, but is not responsible for

Omissions or errors and the consequences caused thereby.

1.2 Compressed Air Safety

Any contact with quickly escaping air or bursting parts of the compressed air system

can lead to serious injuries or even death.

Do not exceed the maximum permitted pressure

Only use pressure tight installation material.

Avoid getting hit by escaping air or bursting parts.

The system must be pressure-less during maintenance work.

1.3 Electrical Safety

Any contact with energised parts of the product, may lead to an electrical shock which

can lead to serious injuries or even death.Consider all regulations for electrical installations.

The system must be disconnected from any power supply during maintenance work.

Any electrical work on the system is only allowed by authorised qualified personal.

1.4 Installing the Flow Meter, Calibration & Maintenance

The product must be installed properly and frequently calibrated, otherwise it may

lead to the wrong measurement values, which can lead to wrong results.

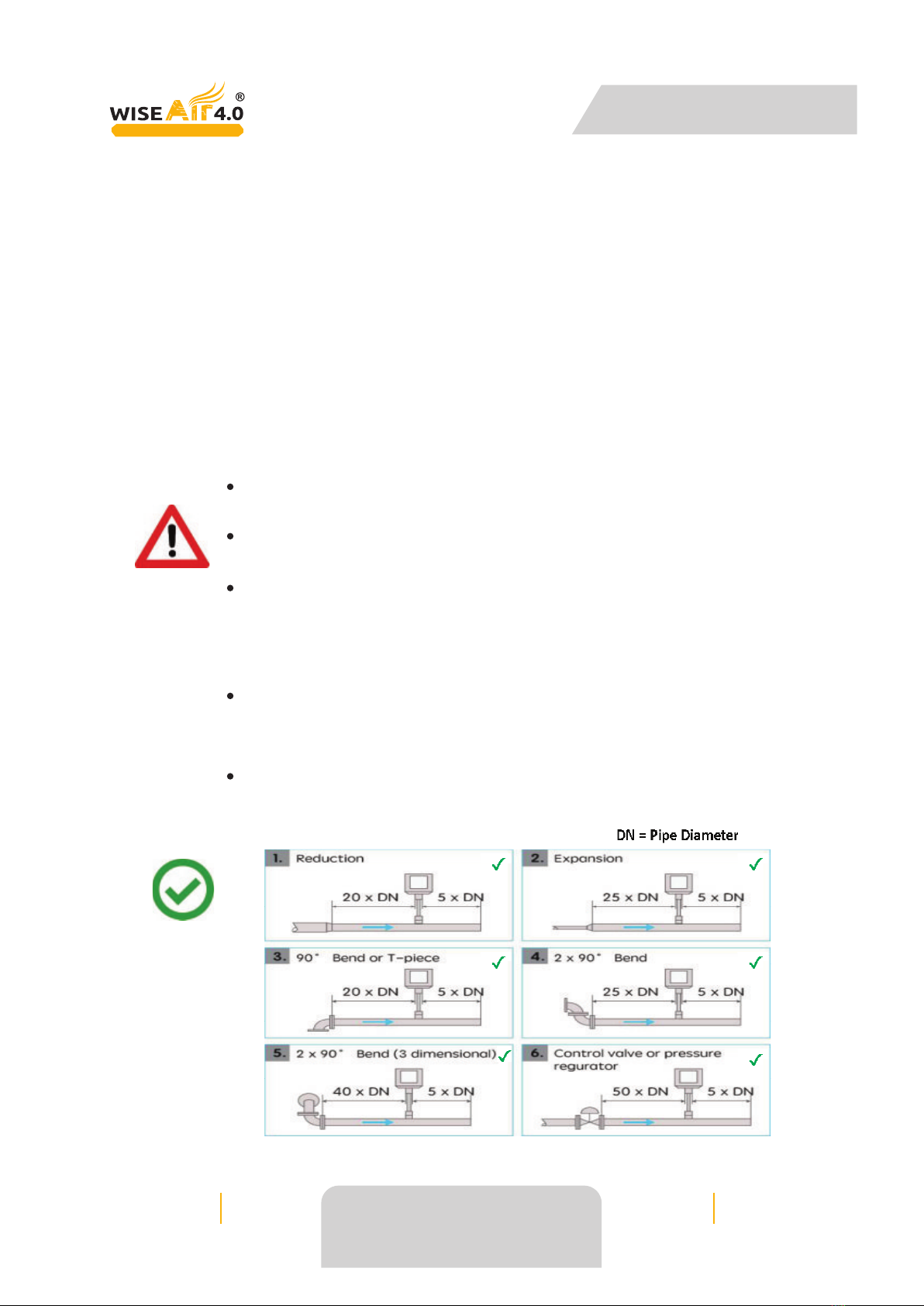

Always Observe the Direction of Flow When installing the Sensor. The

Direction is Indicated on the Housing.

Do Not Exceed the Maximum Operation Temperature at the Sensors Tip.

Avoid Condensation on the Sensor Element as this will affect the accuracy

enormously.

Please observe national regulations before/during installation and

operation.

Do not disassemble the product.

Always use a spanner to mount the product properly

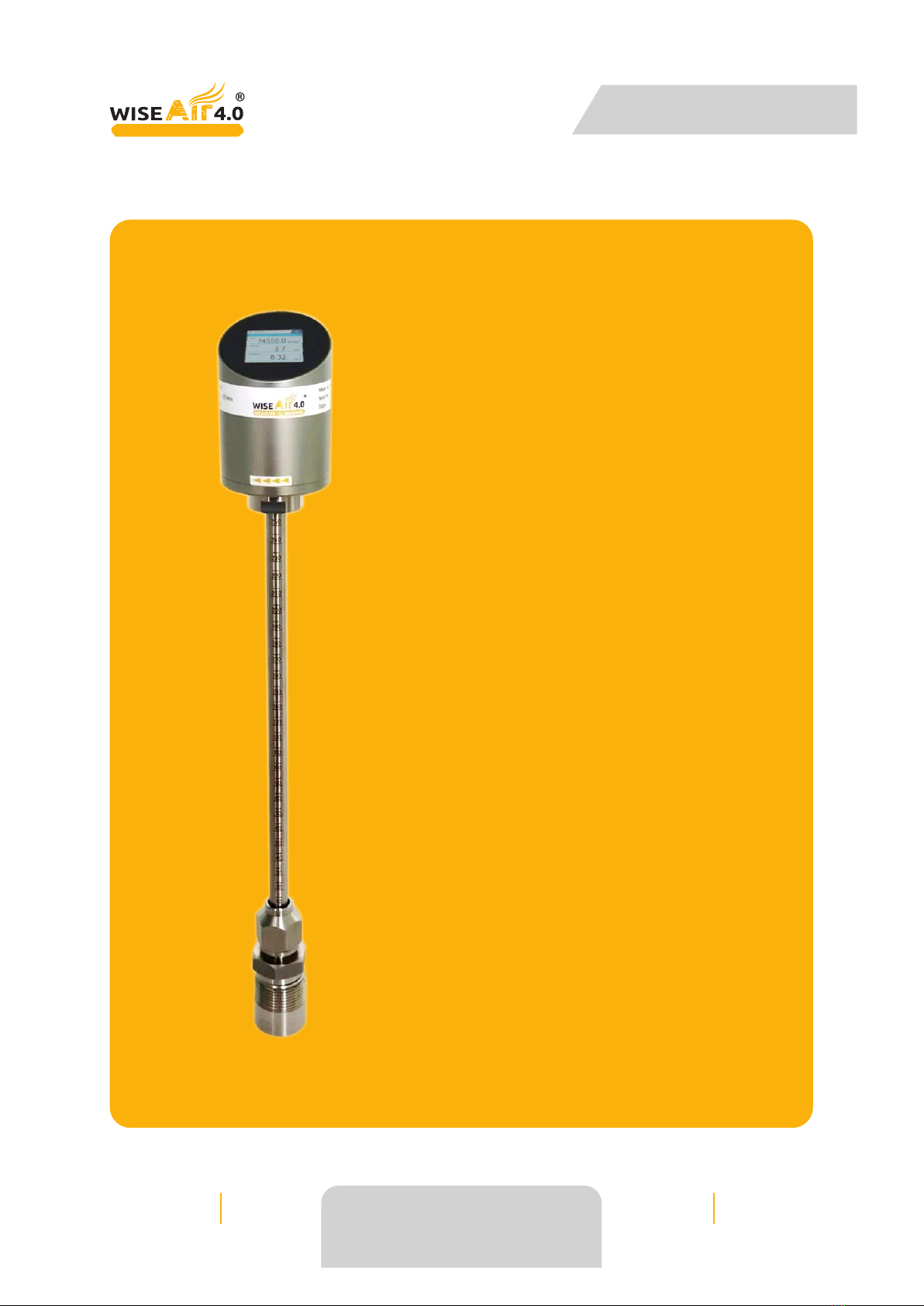

WAFS 104

THERMAL FLOW SENSOR