Content

1. INTRODUCTION..................................................................................................................................1

1.1 INTENDED USE.............................................................................................................................1

1.2 SAFETY REQUIREMENTS ...........................................................................................................1

1.3 SAFETY ADVICE...........................................................................................................................1

1.4 DISCLAIMER .................................................................................................................................2

2. TERMS OF WARRANTY.....................................................................................................................3

3. TECHNICAL INFORMATION ..............................................................................................................4

3.1 DESCRIPTION OF TYPES............................................................................................................4

3.2 SCOPE OF DELIVERY..................................................................................................................4

3.3 ORDER INFORMATION ................................................................................................................4

3.4 CODES / CERTIFICATES / APPROVALS.....................................................................................4

4. TECHNICAL DATA..............................................................................................................................5

4.1 GENERAL INFORMATION............................................................................................................5

4.2 ELECTRICAL DATA.......................................................................................................................5

4.3 MATERIALS ...................................................................................................................................8

4.4 PRESSURE RANGE......................................................................................................................8

4.5 DIMENSIONS.............................................................................................................................. 11

4.6 SECTIONAL VIEWS ................................................................................................................... 12

4.7 DESCRIPTION OF OPERATION ............................................................................................... 28

4.8 PERFORMANCE CHARACTERISTIC TABLE ........................................................................... 29

5. APPLICATIONS................................................................................................................................ 31

5.1 GENERAL ................................................................................................................................... 31

5.2 DETERMINATION OF THE DELIVERY HEAD .......................................................................... 32

5.3 DETERMINATION OF THE REQUIRED FLOW......................................................................... 32

5.4 ADAPTATION TO PLANT REQUIREMENTS............................................................................. 33

5.5 USE OF FREQUENCY CONVERTERS ..................................................................................... 34

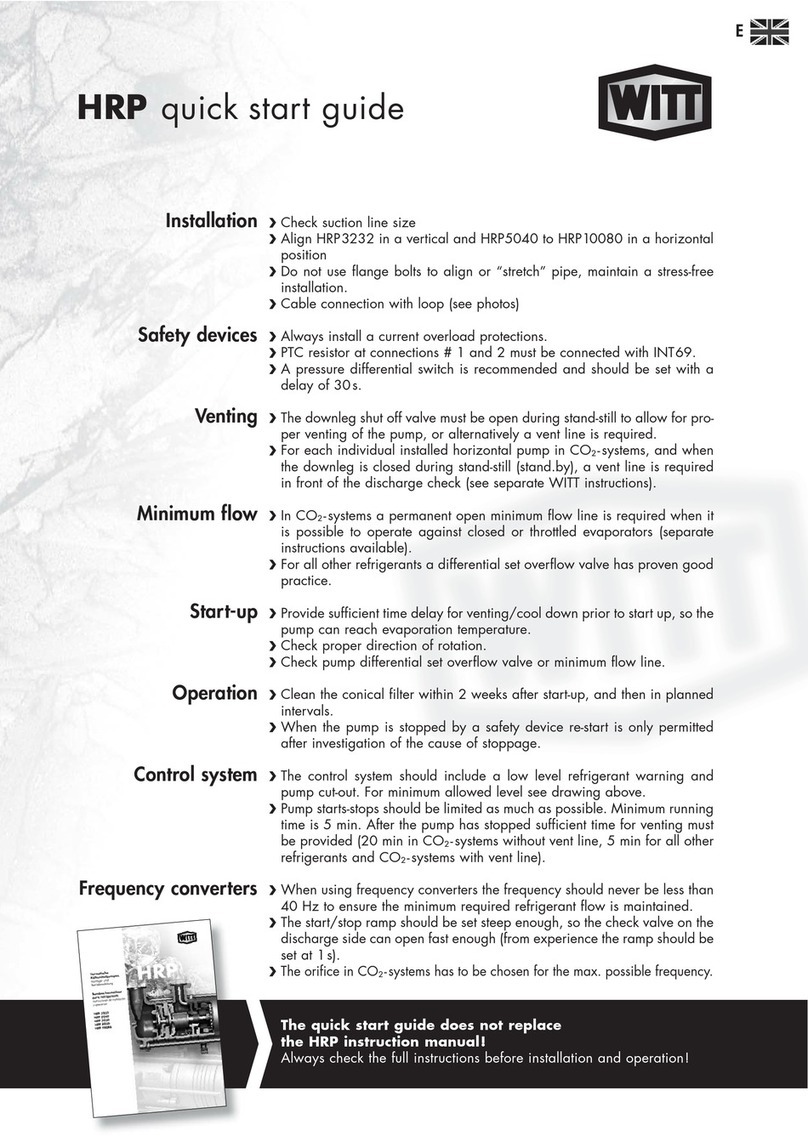

6. INSTALLATION INSTRUCTIONS.................................................................................................... 35

6.1 PUMP ARRANGEMENT............................................................................................................. 35

6.2 PUMP CONNECTION................................................................................................................. 35

6.3 DOWNLEG DESIGN ................................................................................................................... 37

6.4 PUMP DISCHARGE LINE .......................................................................................................... 38

6.5 PROTECTION OF THE PUMP ................................................................................................... 39

6.6 ELECTRICAL INFORMATION.................................................................................................... 44

7. TRANSPORT AND STORAGE ........................................................................................................ 49

8. INSTALLATION AND APPLICATION.............................................................................................. 50

8.1 PREPARING THE PUMP FOR INSTALLATION ........................................................................ 50

8.2 MOUNTING INSTRUCTIONS..................................................................................................... 50