INIRA®

Revision: 02 2022-D050733 en-1

Table of Contents

1 About this manual ................................................................................................2

1.1 Information symbols and cross references ..........................................................2

1.2 Scope of delivery .................................................................................................2

2 Safety.....................................................................................................................2

2.1 EC/EU Directive ...................................................................................................3

2.1.1 Machinery Directive.........................................................................................3

2.2 Personnel.............................................................................................................3

2.3 Intended use ........................................................................................................3

2.4 Reasonably foreseeable misuse..........................................................................3

2.5 General safety instructions ..................................................................................3

2.6 Structure of warning instructions..........................................................................3

2.6.1 Safety symbols ................................................................................................4

2.6.2 Signal words....................................................................................................4

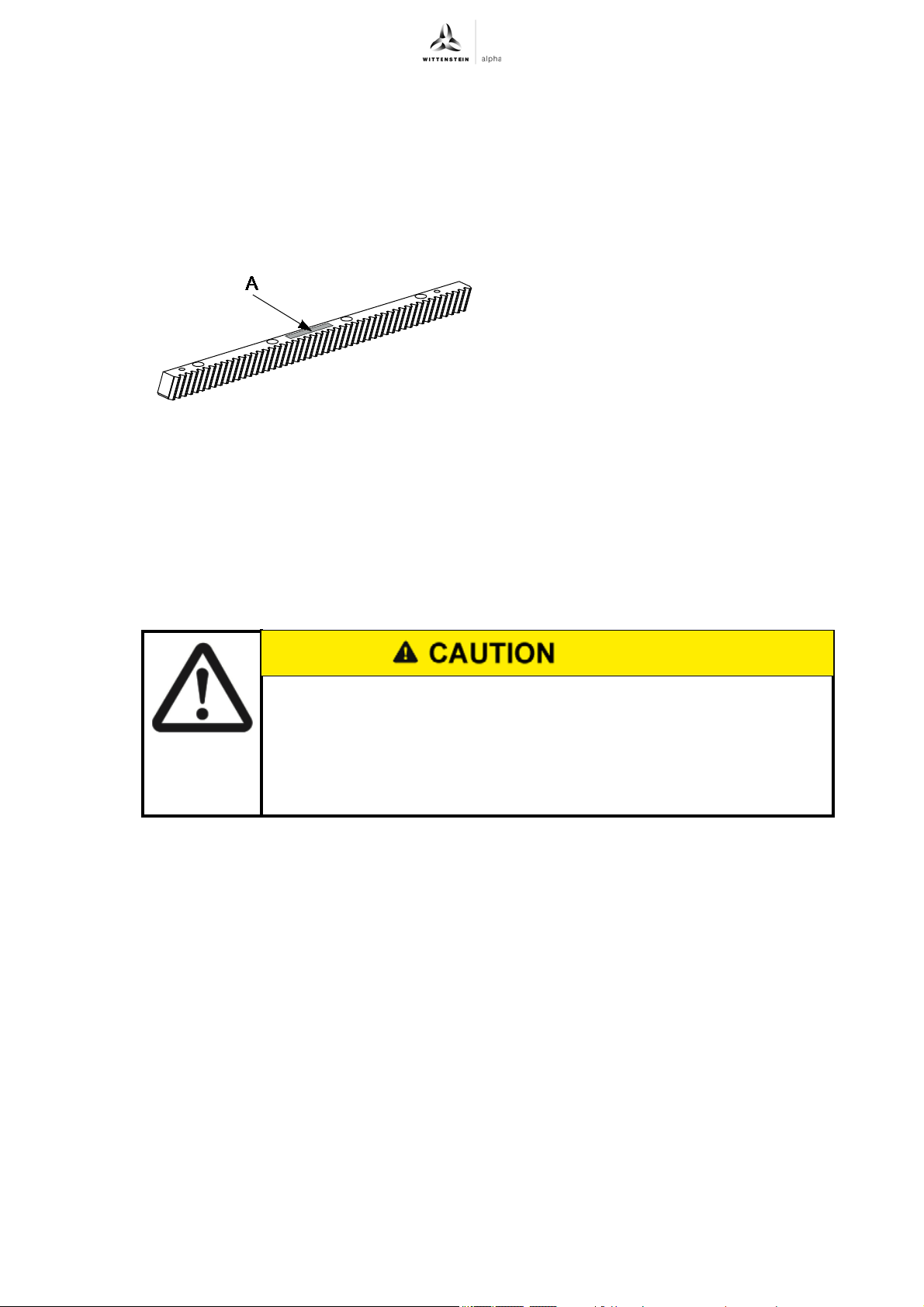

3 Description of racks.............................................................................................5

3.1 Ordering code / Name plate.................................................................................5

4 Transport and storage .........................................................................................5

4.1 Packaging ............................................................................................................5

4.2 Transport..............................................................................................................5

4.3 Storage ................................................................................................................5

5 Assembly ..............................................................................................................6

5.1 Requirements in respect of installation location and mounting base ...................6

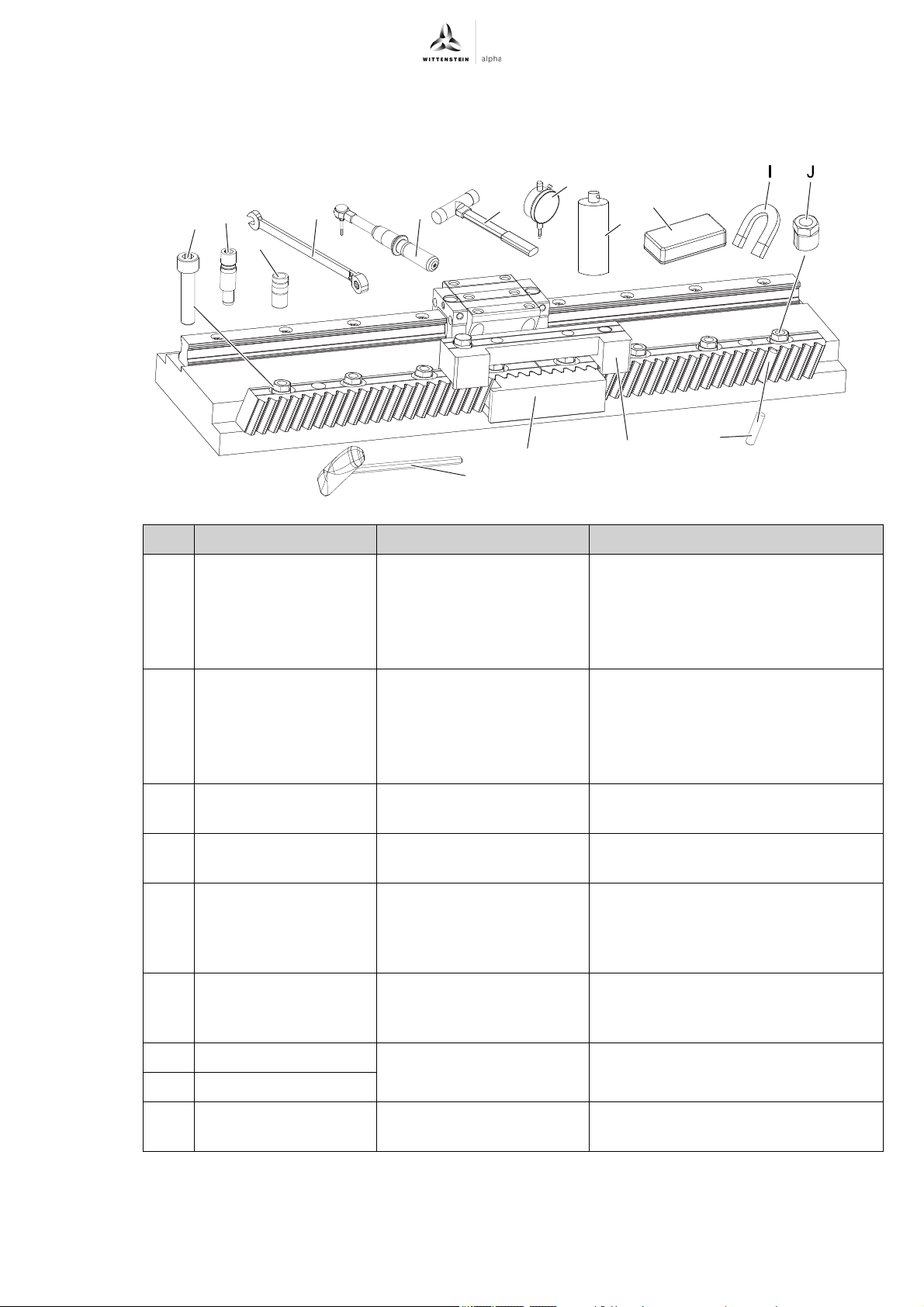

5.2 Required tools and assembly material.................................................................7

5.3 Preparations.........................................................................................................8

5.3.1 After the cleaning ............................................................................................9

5.4 Mounting the racks.............................................................................................10

5.4.1 Assemble first rack with INIRA clamping.......................................................10

5.4.2 Assembling subsequent racks.......................................................................11

5.4.3 Checking the transition between the racks....................................................12

5.4.4 Correct the transition between the racks with INIRA adjusting .....................13

5.4.5 Mounting additional racks..............................................................................14

5.5 Checking the parallelism of all racks..................................................................14

5.6 Pinning the racks ...............................................................................................14

5.6.1 Pinning the racks (conventional) ...................................................................14

5.6.2 Pinning the racks with INIRA pinning ............................................................14

6 Startup and operation ........................................................................................16

7 Maintenance and disposal.................................................................................17

7.1 Disassembly / replacement................................................................................17

7.2 Disposal .............................................................................................................17

8 Malfunctions .......................................................................................................17

9 Appendix .............................................................................................................18

9.1 Weight of racks ..................................................................................................18

9.2 Information for mounting the racks ....................................................................18

9.2.1 Overview of the required fastening screws ...................................................18

9.2.2 Overview of the mounting kit MKP (mounting pin) ........................................18

9.2.3 Overview of tool sizes ...................................................................................19

9.2.4 Tightening torques for assembly bushings....................................................19

9.3 Specifications for mounting onto a mounting base ............................................19

9.4 Maximum height of the stop surface on the machine bed .................................19

9.5 Permissible parallelism deviation of the assembly surface................................20

9.6 Permissible roll size fluctuation at the rack transition ........................................20

9.7 Permissible roll size fluctuation within an axis ...................................................20

9.8 Overview of the assembly accessory kit ............................................................21

9.9 Tightening torques for common thread sizes in general

mechanical engineering .....................................................................................21