LP+/ LPB+

Revision: 05 2022-D018479 en-1

Contents

1 Regarding this manual.........................................................................................2

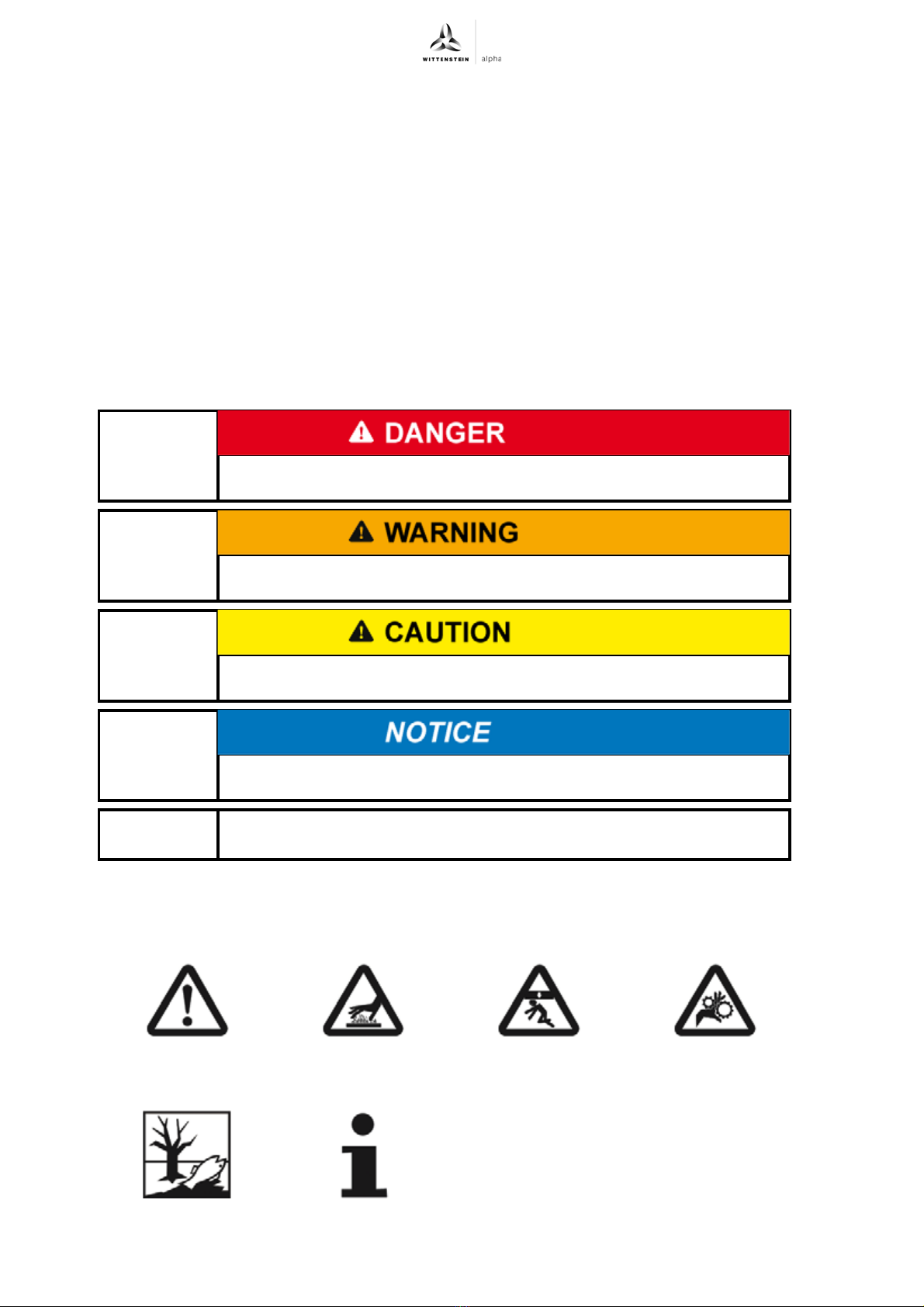

1.1 Signal words ........................................................................................................2

1.2 Safety symbols.....................................................................................................2

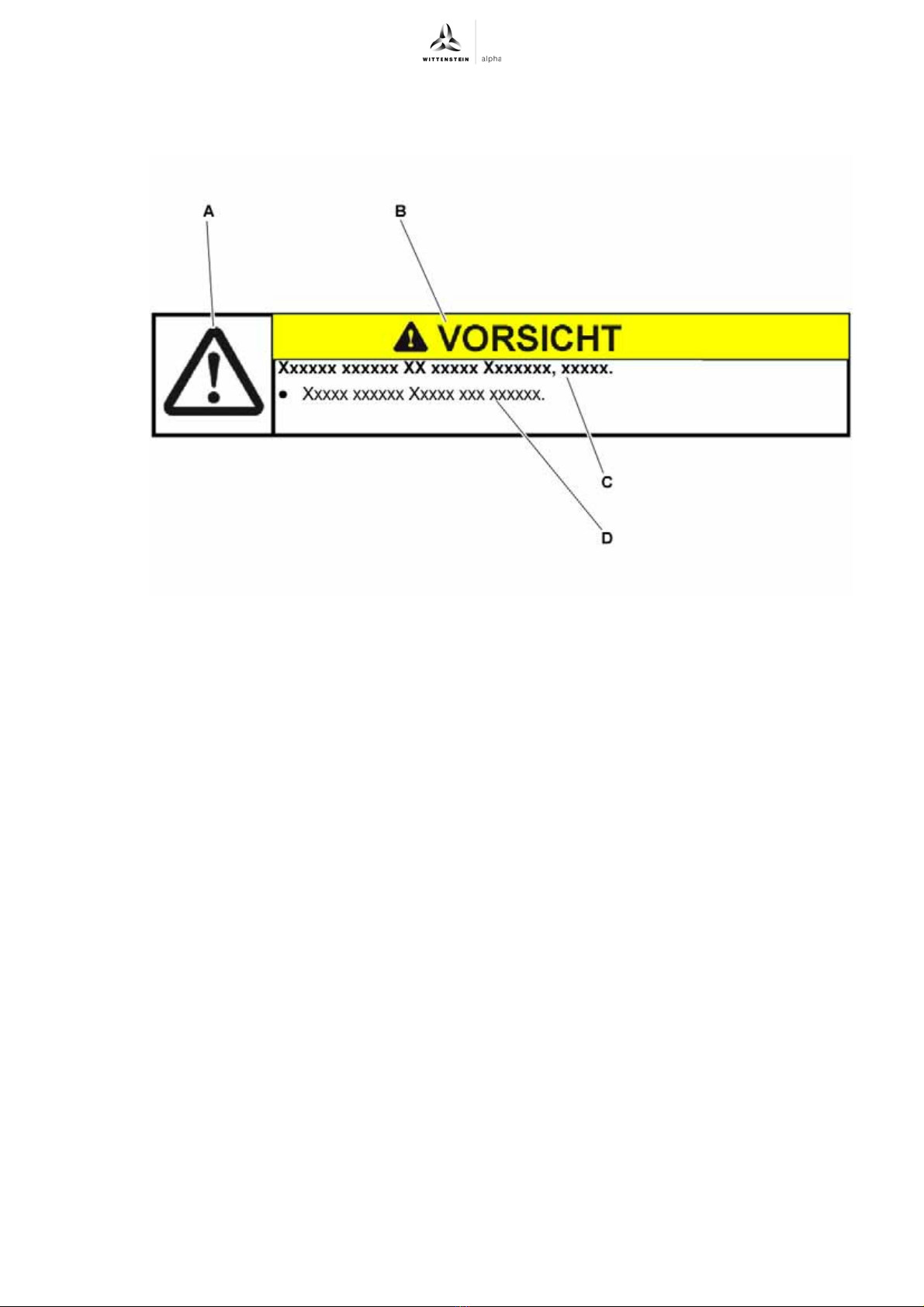

1.3 Design of the safety instructions ..........................................................................3

1.4 Information symbols.............................................................................................3

2 Safety.....................................................................................................................4

2.1 EC – Machinery directive .....................................................................................4

2.2 Dangers ...............................................................................................................4

2.3 Personnel.............................................................................................................4

2.4 Intended use ........................................................................................................4

2.5 Reasonably predictable misuse ...........................................................................4

2.6 Guarantee and liability .........................................................................................4

2.7 General safety instructions ..................................................................................5

3 Description of the gearhead................................................................................6

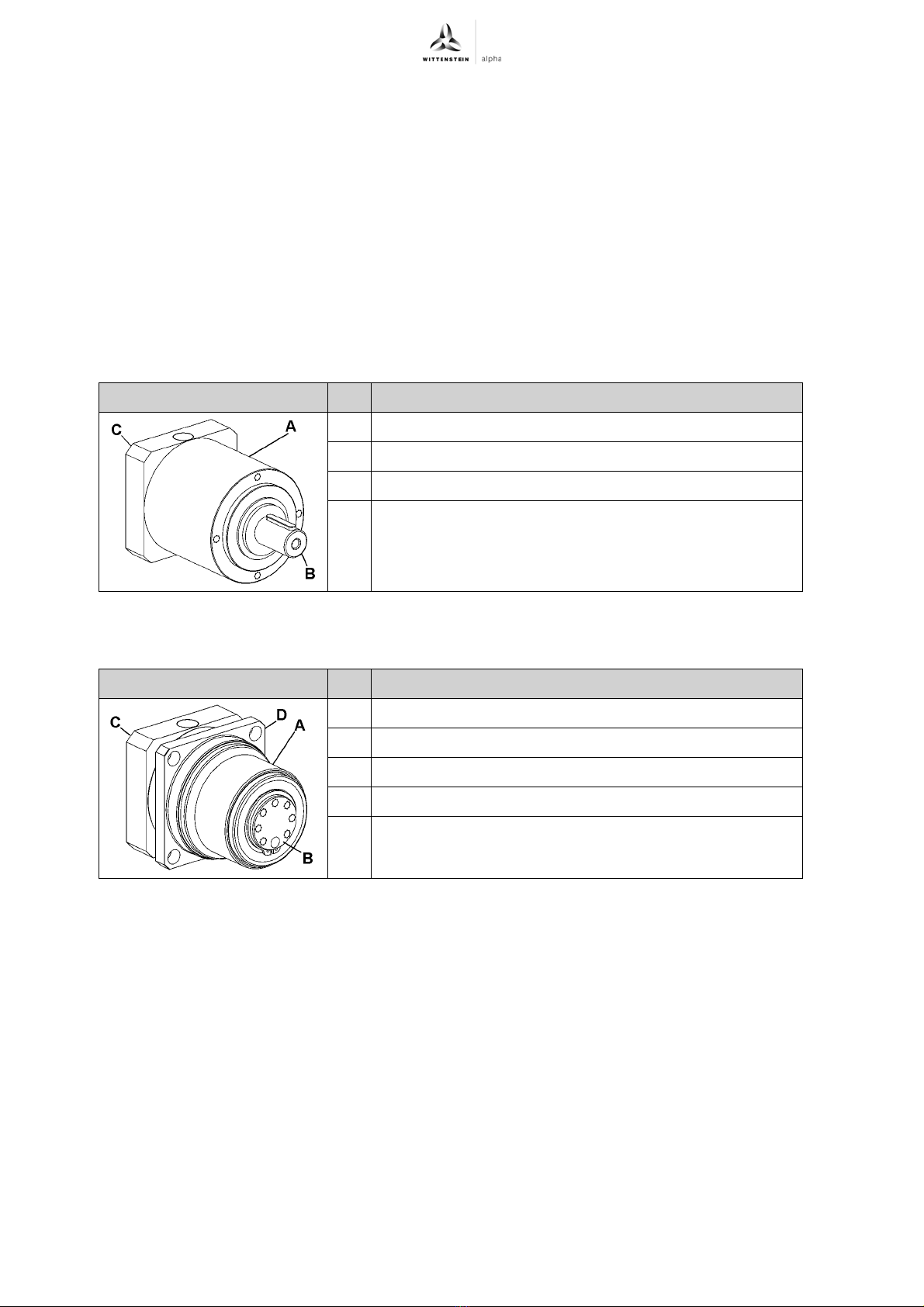

3.1 Overview of the gearhead components ...............................................................6

3.1.1 Overview of the gearhead components LP+....................................................6

3.1.2 Overview of the gearhead components LPB+.................................................6

3.2 Type plate ............................................................................................................7

3.3 Ordering key ........................................................................................................7

3.4 Performance statistics..........................................................................................8

3.5 Weight..................................................................................................................8

4 Transport and storage.........................................................................................9

4.1 Scope of delivery .................................................................................................9

4.2 Packaging ............................................................................................................9

4.3 Transport..............................................................................................................9

4.4 Storage ................................................................................................................9

5 Assembly ............................................................................................................10

5.1 Preparations.......................................................................................................10

5.2 Mounting the gearhead to a machine (LPB+).....................................................11

5.3 Mounting the motor onto the gearhead (LP+/ LPB+) ..........................................12

5.3.1 Pre-mounting adapter plate (only LPB+) .......................................................12

5.3.2 Mounting the motor (LP+/ LPB+) ...................................................................13

5.4 Mounted components on the gear output side...................................................14

5.4.1 Mountings on the output flange (LPB+) .........................................................14

5.5 Mounting the gearhead to a machine (LP+) .......................................................15

6 Startup and operation........................................................................................16

7 Maintenance and disposal.................................................................................17

7.1 Maintenance work..............................................................................................17

7.1.1 Visual inspection ...........................................................................................17

7.1.2 Checking the tightening torques....................................................................17

7.2 Startup after maintenance work .........................................................................17

7.3 Maintenance schedule .......................................................................................17

7.4 Notes on the lubricant used ...............................................................................18

7.5 Disposal .............................................................................................................18

8 Malfunctions.......................................................................................................19

9 Appendix.............................................................................................................20

9.1 Specifications on mounting onto a motor...........................................................20

9.2 Specifications on mounting onto a machine ......................................................20

9.3 Tightening torques for common thread sizes in general mechanics ..................21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com