Operating manual GFZ / GFM / GEZ Page 3 of 30 B0112

Table of contents

1. Important notes on this operation manual.....................................................................5

1.1 Users........................................................................................................................5

1.2 Obligation to read.....................................................................................................5

1.3 What to do in case of questions................................................................................5

1.4 Operation manual.....................................................................................................5

1.4.1 Applicability ..............................................................................................................5

1.4.2 Content and purpose................................................................................................5

1.4.3 Location....................................................................................................................6

1.4.4 Meanings of safety notes and safety symbols...........................................................6

2. Identification....................................................................................................................7

2.1 Product brand and type designation .........................................................................7

2.2 Product version.........................................................................................................7

2.3 Product marking .......................................................................................................7

2.4 Manufacturer and contact address............................................................................7

2.5 Conformity................................................................................................................7

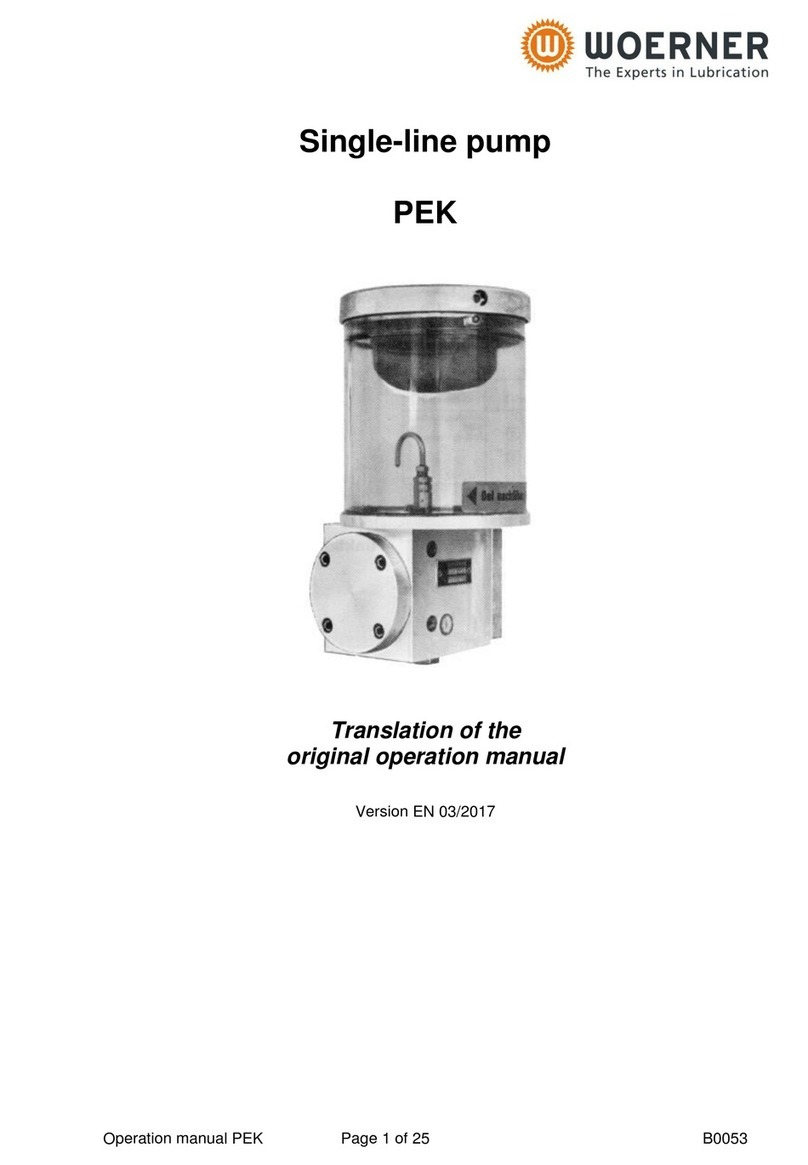

3. Product description.........................................................................................................8

3.1 Purpose of use .........................................................................................................8

3.2 Limits of use.............................................................................................................8

3.3 Ambient conditions...................................................................................................8

3.4 Conventional usage..................................................................................................9

3.5 Technical data..........................................................................................................9

3.5.1 Assemblies...............................................................................................................9

3.5.2 Dimensions...............................................................................................................9

3.5.3 Technical data..........................................................................................................9

4. Functional description ..................................................................................................10

4.1 Components...........................................................................................................10

4.1.1 GFZ-B, GFZ-C, GFZ-D...........................................................................................10

4.1.2 GFZ-N....................................................................................................................10

4.1.3 GFZ-L / GFZ-L01....................................................................................................10

4.1.4 GFM-F, GFM-G......................................................................................................10

4.1.5 GFM-N....................................................................................................................10

4.1.6 GFM-L / GFM-L01..................................................................................................10

4.1.7 GEZ-B / GEZ-C ......................................................................................................10

4.2 Energy supply.........................................................................................................10

4.3 Function..................................................................................................................11

5. Safety notes...................................................................................................................11

5.1 Basic principle ........................................................................................................11

5.2 Requirements on user training................................................................................11

5.3 Safety facilities........................................................................................................12

5.4 Accident prevention................................................................................................12

5.5 Residual risks.........................................................................................................12

5.6 Incorrect applications..............................................................................................12

5.7 General safety regulations and duties.....................................................................13

5.8 Special features of the types meeting the requirements of the directive 2014/34/EU

(ATEX)...............................................................................................................................14

5.9 Disclaimer...............................................................................................................14

6. Transportation, installation, commissioning and shutdown......................................15

6.1 Transportation ........................................................................................................15

6.2 Unpacking ..............................................................................................................15

6.3 Installation..............................................................................................................15

6.3.1 GFZ series..............................................................................................................15