Leaflet-No. 0301 EN

Page 4 of 6

Leaflet-No. 0301 EN

Page 3 of 6

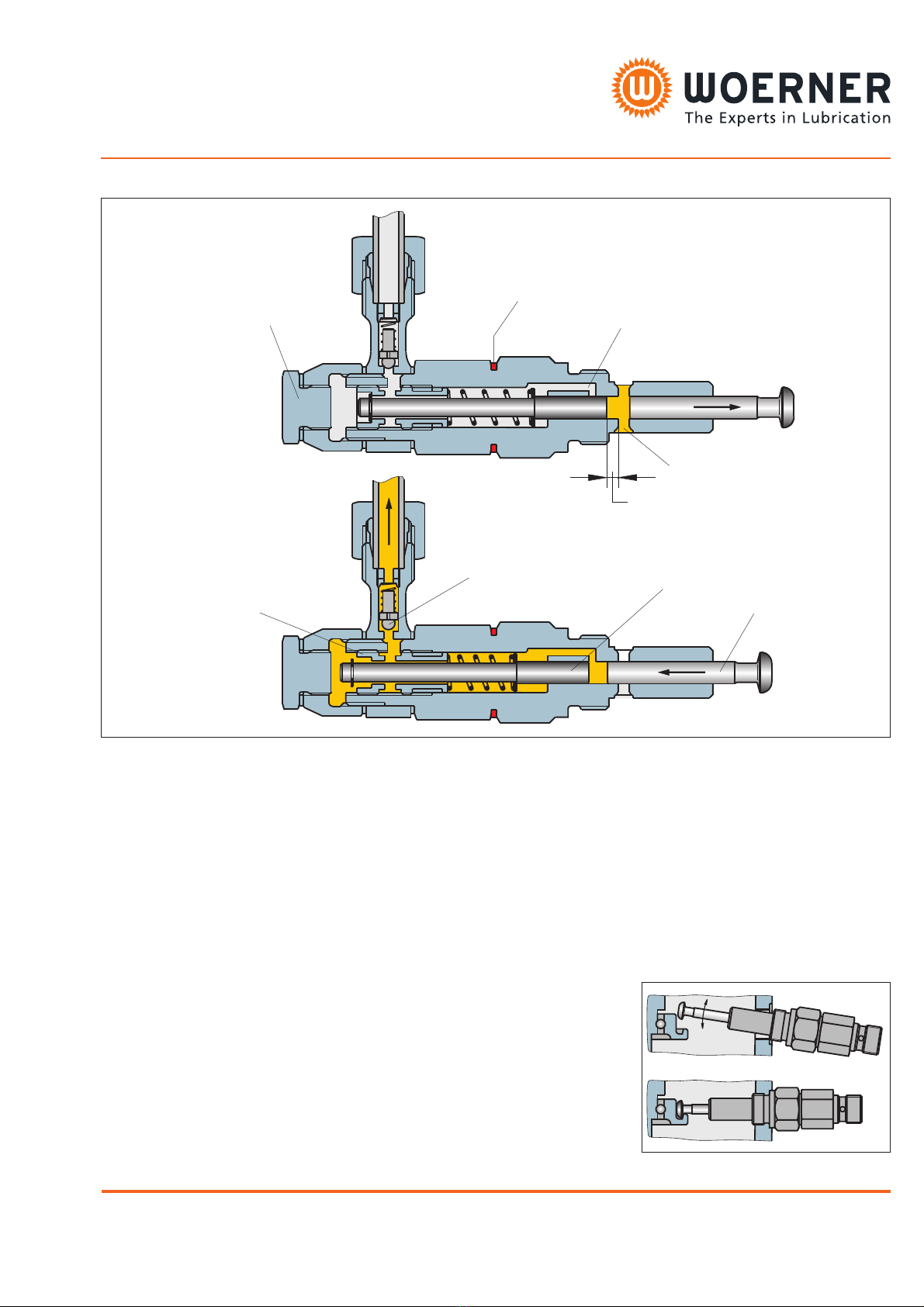

Operation of pump elements:

The suction stroke (fig. 1) is accomplished

by the delivery piston (1) and the control

piston (2). During that operation the delivery

piston (1) is actuated by the eccentric shaft,

and the control piston (2) by the spring. The

control piston closes the pressure hole (3)

and, depending on the set delivery capacity,

remains at a certain position. With the

delivery piston moving on, a vacuum will

build up within the dosage area. After

opening the suction hole (4) by the delivery

piston, the lubricant starts to be sucked off

the reservoir.

In case of pressure stroke (fig. 2) the

delivery piston (1) moves to the left. As a

result, the suction hole (4) will be closed

with the lubricant available between the

delivery and control pistons (2) being

shifted until it clears the pressure hole (3)

and the lubricant is delivered through the

delivery piston up to the outlet. The pumps

are supplied with their delivery capacities

being set at maximum, i.e. at full stroke

setting.

Delivery volume adjustment:

The can be adjusted

continuously between 25 and 100% of the

nominal delivery volume. After having

removed lock screw , the stroke is to be

changed by means of the enclosed spanner

through adjustment nipple . When turning

the nippe to the right, delivery volume will

decrease. At the adjustment nipple, there is

a hexagon against which a spring loaded

piston is pressing radially. Thus, any

independent change of the delivery volume

will be prevented. At the same time, the

latching serves as a measure for setting the

delivery volume. Six latches equal one

rotation of the adjustment nipple and a

reduction of the nominal delivery volume by

33%. 14 latches (minimum) equal a delivery

volume reduction down to 25% of the

nominal delivery volume.

delivery volume

7

6

The element with a piston diameter of

8 mm = 0,15 cm³/stroke is marked with a red

ring (see fig. 1).

Installation of pump elements:

If another pump element is to be installed in

the lubrication pump subsequently, proceed

as shown in the drawing on the right:

Insert pump element at an upwards

inclination into the locating hole with the

plunger pulled out about half way. To

facilitate installation and putting into

operation, fill the bore taking up the plunger

with grease. Bring into horizontal position

and screw in only after the plunger head

abuts the pressure ring and engages in the

groove of the pressure ring.

Reservoir / level monitoring:

When using a "K" sequence piston, the

utilisable reservoir capacity decreases by

approx. 2,5l.

I = Filling connector

(Connection thread G3/8)

II = Return connector G1/8

Remark on the dimensional drawings:

Level monitoring suitable for

delivery of

without level

monitoring

Oil as of 20cP

grease up to

NLGI-cl. 2

Float Oel as of 20cP

Proximity

switch

Grease of NLGI-

cl.1 and 2

Follow-up

piston

Grease up to

NLGI-cl. 2

Reservoir

capacity

Level monitoring

options

Float:

at min. level

Proximity switch:

signal intermit-

tently, min. level

Float:

at min. and

max. level

Proximity switch:

signal intermit-

tently, min. level

Float:

at min. and

max. level

Follow-up piston:

at min. and

max. level

Reservoir

capacity Reservoir material

Polycarbonate

transparent

Polyamide

transparent

Zinced steel

Polyester

fibreglass reinforced

Type A [mm] Weight [kg]

Type B [mm] Weight [kg]

Fig. 1 Suction stroke

Fig. 2 Delivery stroke

Plug (7)

red ring marking the element with

piston 8 = 0,15 cm³/strokeÆ

Pressure passage (3)

Suction opening (4)

Adjusting nipple (6)

Check valve (5)

Control spool (2)

Delivery plunger (1)

Delivery volume

Motor speed 1 / 4,5 25

EUGEN WOERNER GmbH & Co. KG

Postfach 1661 DE-97866 Wertheim

Am Eichamt 8 DE-97877 Wertheim

Tel. +49 (0) 9342 803-0

Fax.+49 (0) 9342 803-202 www.woerner.de

info@woerner.de

EUGEN WOERNER GmbH & Co. KG

Postfach 1661 DE-97866 Wertheim

Am Eichamt 8 DE-97877 Wertheim

Tel. +49 (0) 9342 803-0

Fax.+49 (0) 9342 803-202 www.woerner.de

info@woerner.de

- Subject to modifications -

- Subject to modifications -