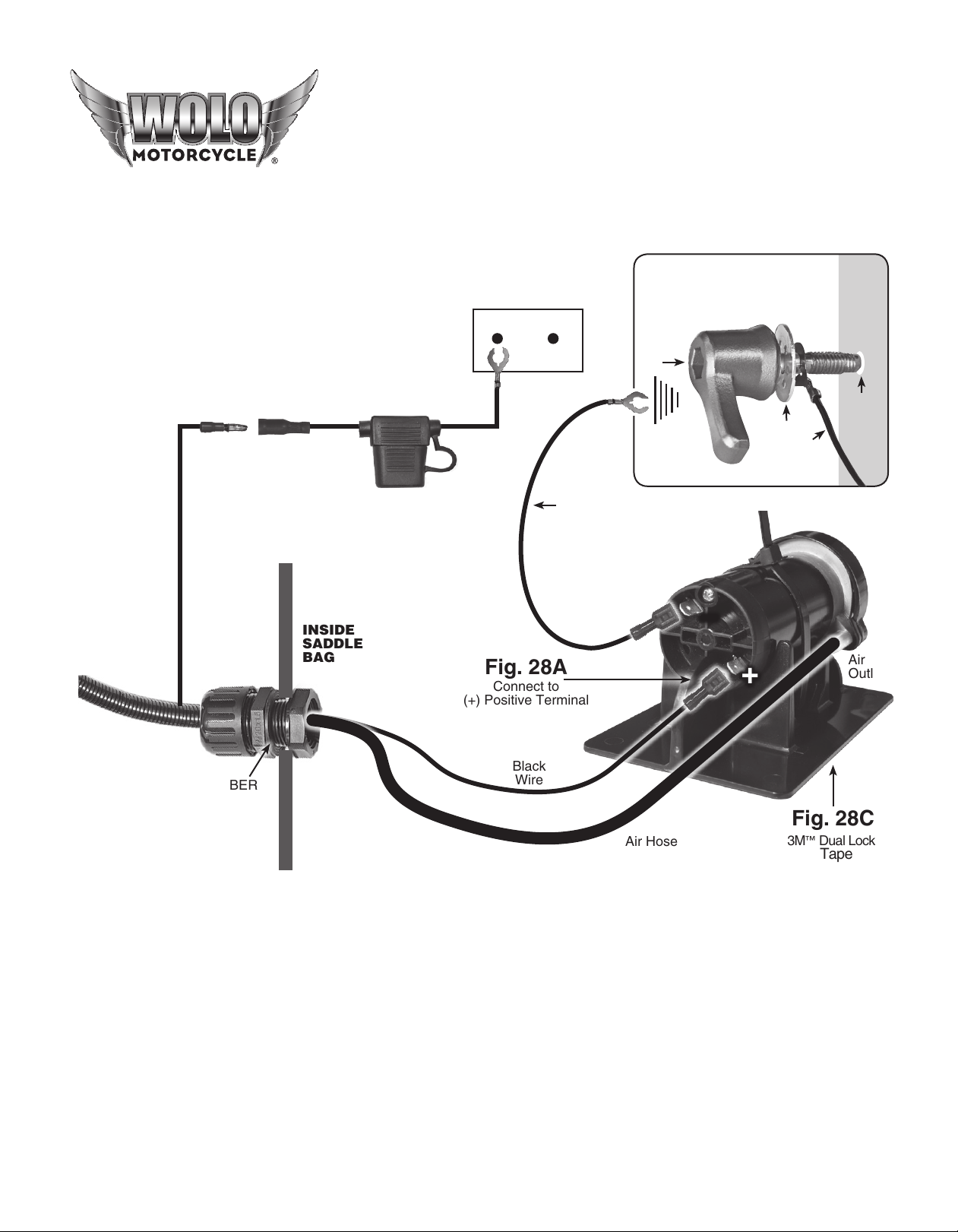

MOUNTING THE COMPRESSOR IN THE SADDLE BAG

The Hideaway Blast comes with a patented compressor bracket, which secures the compressor in

the saddle bag without drilling any holes.

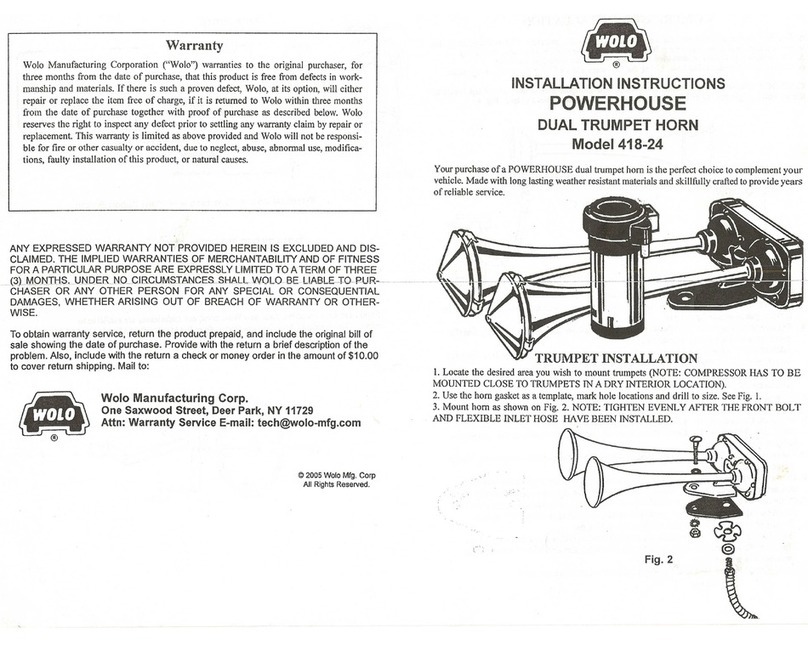

21. Using the longest black plastic tie provided, insert the strap’s end into the mounting bracket’s

retaining slot located on the base of the mounting bracket. Push the strap through the slot. Insert

the strap into the locking end and pull tight. IMPORTANT: The plastic tie has a push tab on the

locking end. When the tab is pressed, it will allow the installer to release the locking hold of the

plastic tie. See Fig. 19.

22. Select the mounting location in the left side saddle bag for the compressor and mounting

bracket. The recommend position is the front facing wall. See Fig. 20 & 21.

IMPORTANT: For best performance, the compressor’s wire terminals should be facing upward,

and the black plastic compressor cover should be facing downward.

23. Use the compressor’s mounting bracket as a template and outline mounting location with a

marking pen. Remove compressor from the saddle bag

24. Route the black flexible tubing under the seat supports to the left side saddle bag. See Fig. 22.

25. The black wire extending from the side of the black flexible tubing is routed to the battery, do not

make any wire connects at this time.

26. A 25/32” hole needs to be drilled into the saddle bag to route the black air hose and black wire to

the compressor. The hole should be drilled from the inside of the saddle bag. See Fig. 23.

IMPORTANT: BEFORE DRILLING THE SADDLE BAG CAREFULLY FOLLOW

STEPS BELOW.

27A. The hole to be drilled should be as close as possible to the location selected for mounting of the

compressor.

27B. Before drilling the access hole into the saddle bag, measure the length of air hose and wire

extending from the black flexible tubing to make sure that they are long enough to connect to the

compressor from the location that the hole will be drilled.

27C. Make sure that hole location selected will be hidden from view.

27D. Make sure that the black flexible tubing and its end connector do not have any sharp bends or

kinks which could restrict the flow air from the compressor to the horn.

CAUTION: Sharp bends in the black air hose can decrease the sound output of the horn.

28. Before the hole is drilled into the saddle bag, carefully inspect the opposite side of the saddle

bag to make sure that there are no wires, cables, hose lines and or component parts that can be

damaged when drilling the hole.

29. It is recommended that the access hole drilled into the saddle bag be deburred so the connector

can provide a watertight fit.

30. Remove the nut from the plastic connector by turning it counterclockwise.

31. Route the black air hose and black wire through the drilled access hole until the connector’s

thread end is extending into the inside of the saddle bag. IMPORTANT: Make sure the rubber

gasket is positioned between the connector and the saddle bag to ensure a watertight fit. See

Fig. 24.

32. Thread the nut back onto the connector, do not tighten.

33. Inspect the black flexible tubing to ensure that there are no sharp bends or kinks.

34. Tighten the nut that secures the nut to the saddle bag.

IMPORTANT: If there is excess black flexible tubing that is causing a kink, or a sharp bend follow the

corrective steps below.

35A. Remove the nut that is securing the hanger bracket of the horn housing. See Fig. 1.

35B. Loosen the nut that is securing the connector to the saddle bag.

35C. Using a thin bladed sharp scissors, carefully insert the blade to cut only the black flexible tubing

at the horn’s end. Cut and remove enough of the flexible tubing to eliminate any kink or bend.

CAUTION: Use care to ensure the scissors do not cut the wires or air hose. See Fig. 25.