2Operation and Maintenance Manual JF Jet Fans V 2008/10

1 General safety notes ..................................................................................................................................................3

1.1 The operator's duty of care ......................................................................................................................................3

1.2 Explanation of the safety symbols used .....................................................................................................................3

1.3 Basic safety measures ............................................................................................................................................3

1.4 Particular kinds of hazards .......................................................................................................................................4

2 Product description ....................................................................................................................................................4

2.1 Stipulated usage ....................................................................................................................................................4

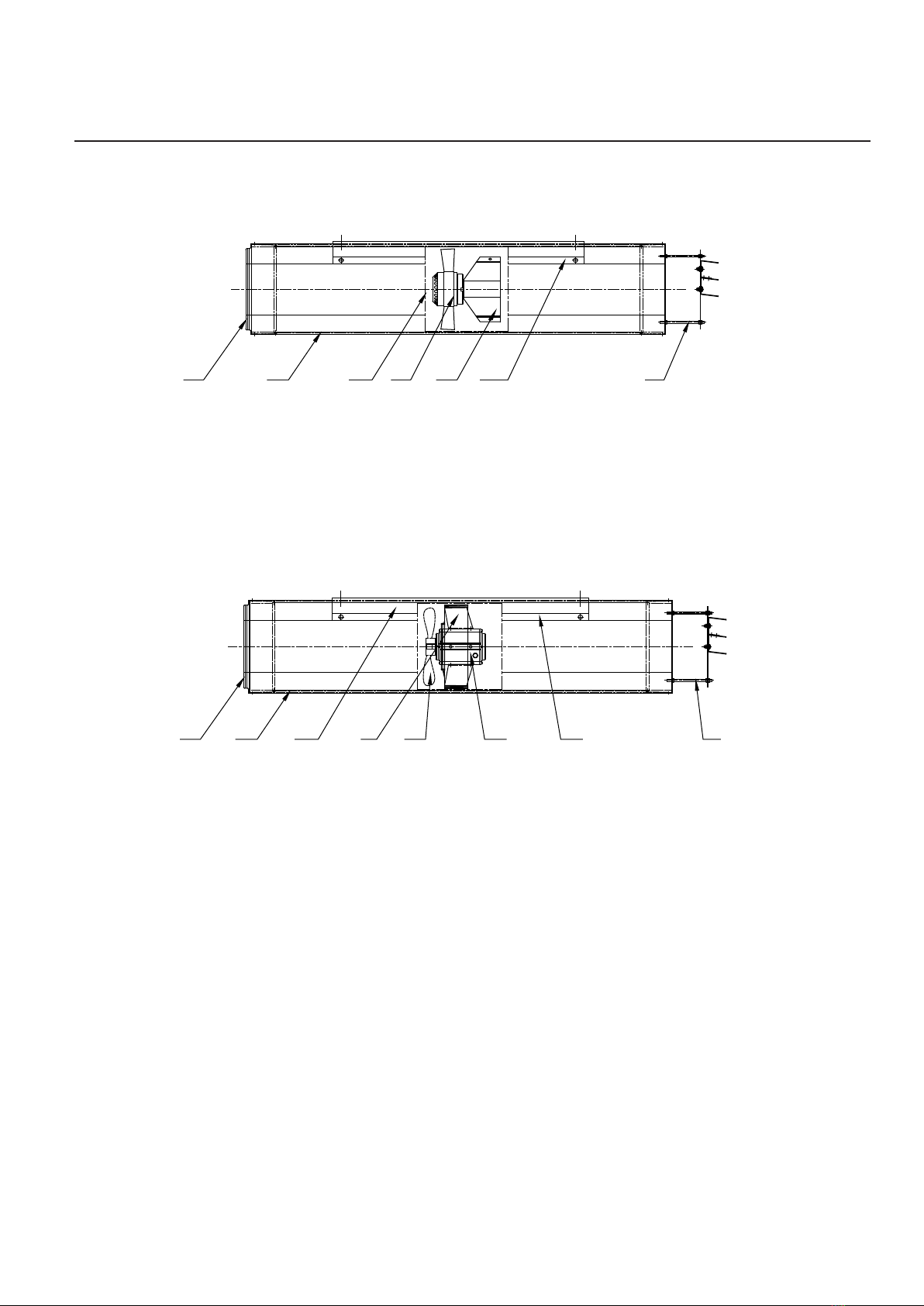

2.2 Construction ..........................................................................................................................................................5

2.2.1 JFU250/...-AE series ........................................................................................................................................5

2.2.2 JFUO/JFRO series ..........................................................................................................................................................5

2.3 Functional description..............................................................................................................................................................5

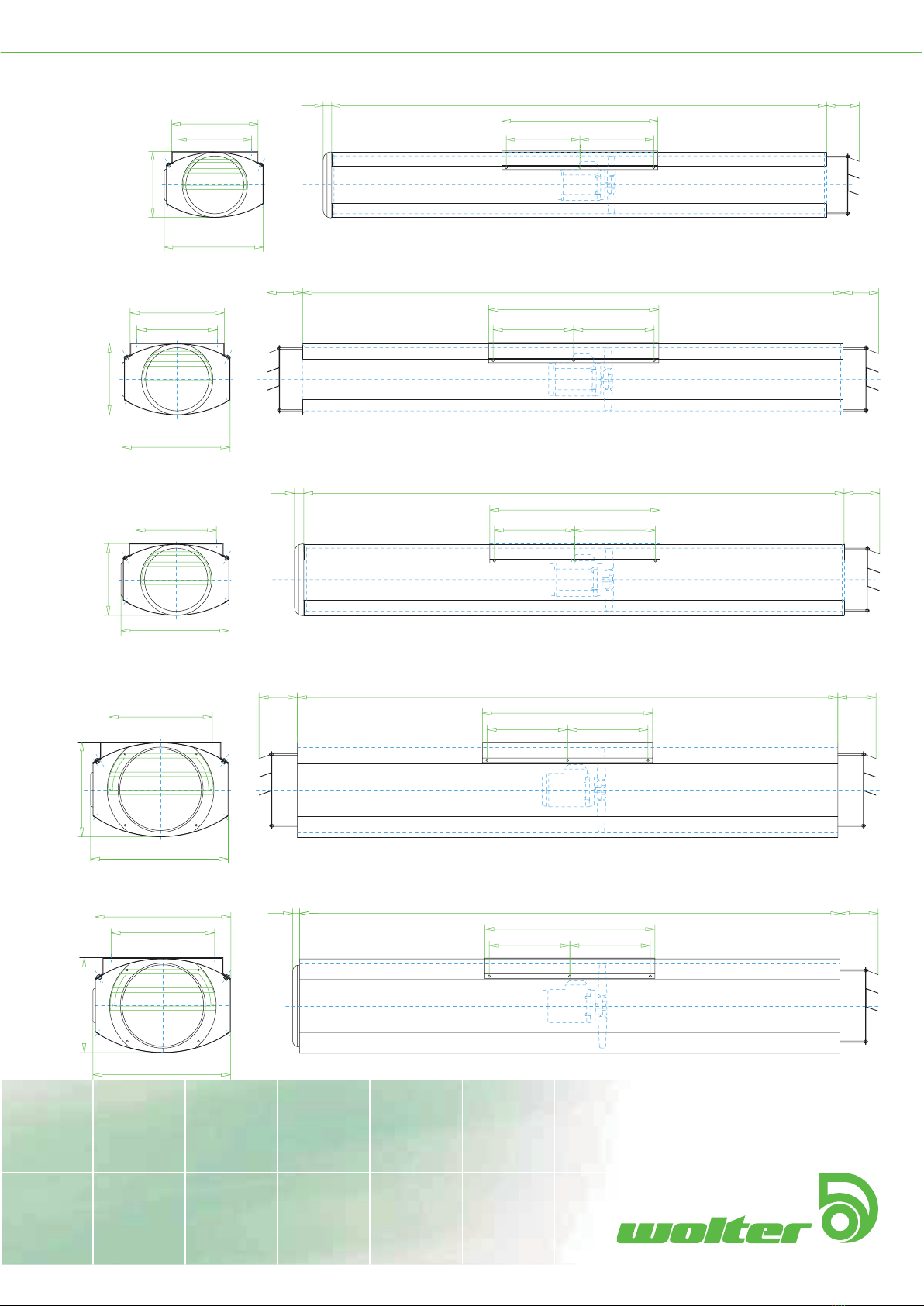

2.4 Dimensions .............................................................................................................................................................6

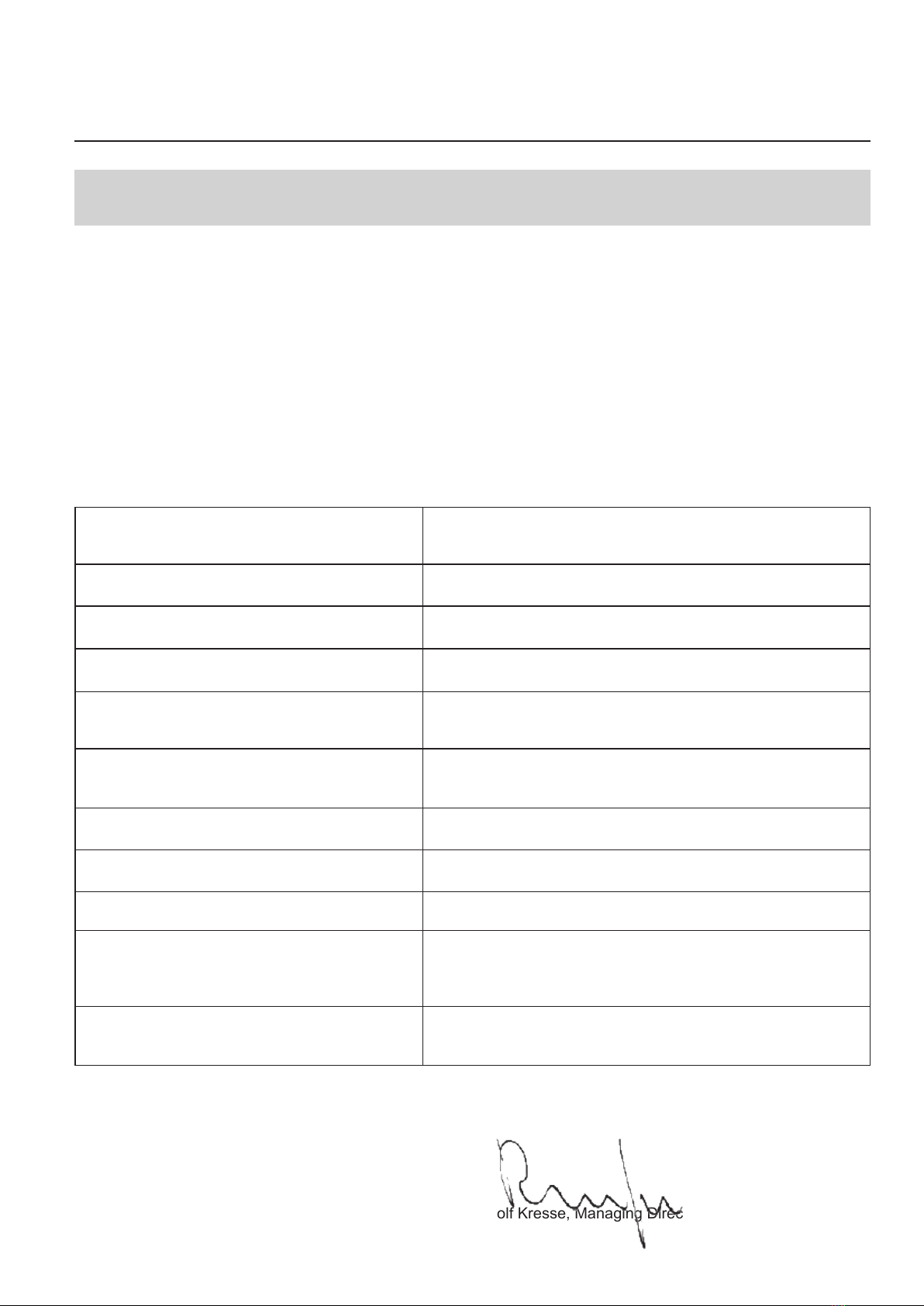

3 EC Declaration of Conformity .....................................................................................................................................7

4 Transportation and Storage .......................................................................................................................................8

4.1 Transportation ........................................................................................................................................................8

4.2 Storage .................................................................................................................................................................8

5 Assembly ...................................................................................................................................................................8

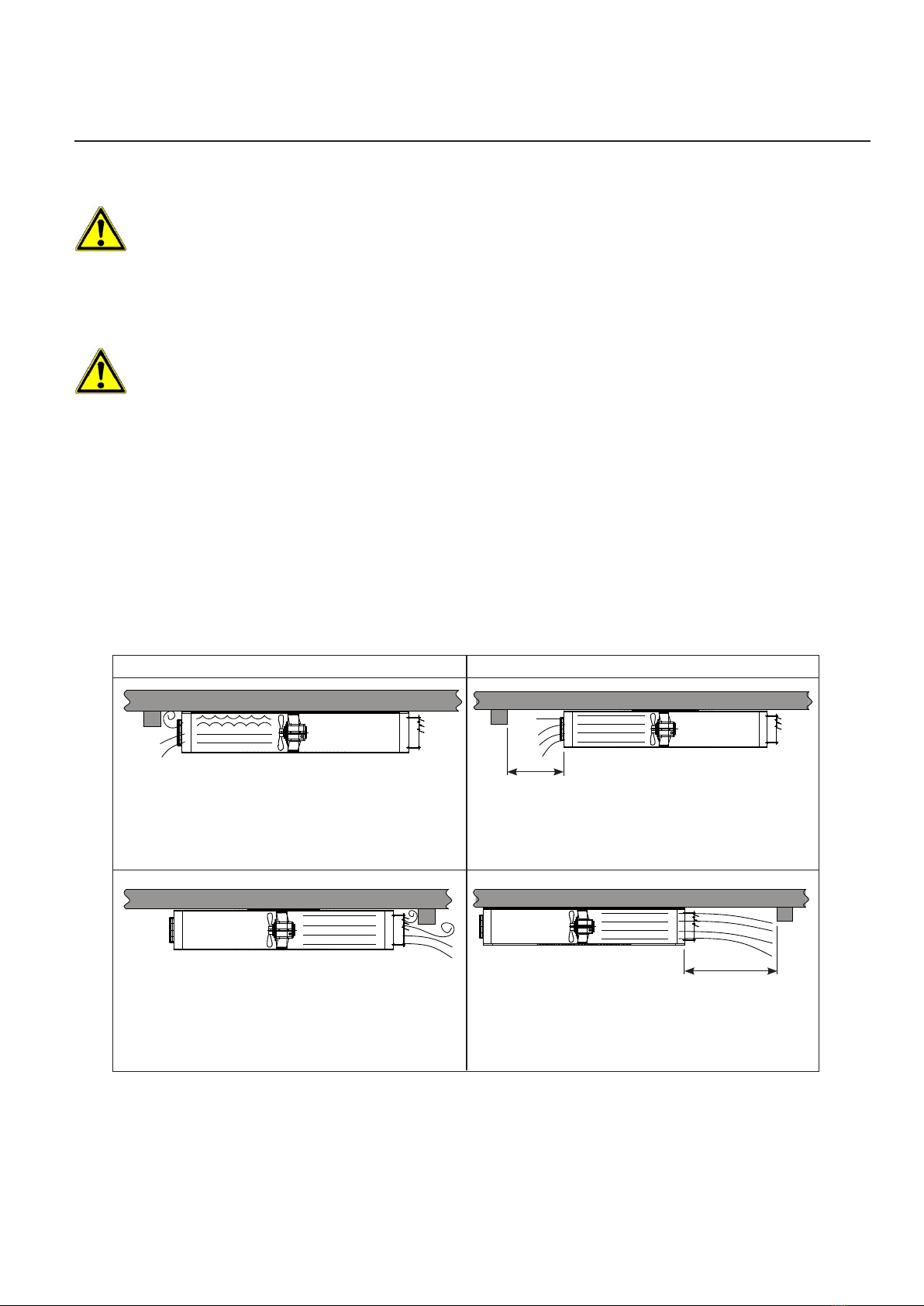

5.1 Inlet and outlet ow conditions ..................................................................................................................................9

6 Initial Start-up ..........................................................................................................................................................10

6.1 Checks prior to initial start-up .................................................................................................................................10

6.2 Starting up the fan for the rst time ..........................................................................................................................10

6.3 Checks after initial start-up .....................................................................................................................................10

7 Help with Malfunctions .............................................................................................................................................11

7.1 Tabular overview of possible malfunctions and aids in eliminating those malfunctions ...................................................11

8 Maintenance ............................................................................................................................................................12

8.1 Servicing .............................................................................................................................................................12

8.2 Overhaul .............................................................................................................................................................13

8.2.1 Removal and installation the motor-fan-assembly ..............................................................................................13

8.2.2 Dismantling the rotor ......................................................................................................................................14

8.2.3 Assembling the rotor ......................................................................................................................................14

8.2.4 Impeller blade pitch angle ...............................................................................................................................15

8.2.5 Motor bearing service intervals ........................................................................................................................15

8.2.6 Instructions on correct bearing replacement ......................................................................................................15

Contents

Table of Contents