• Is the switchgear used suitable for the motor both with respect to the switching functions to be

carried out and also to the switching conditions and switched output of the motor?

• Is the motor protection system set correctly with regard to the motor‘s nominal current? The setting

must be carried out in accordance with the corresponding details contained on the motor

outputplate.

• Has the motor been connected correctly in accordance with the wiring diagram?

The connection schematic supplied by the motor suppliers applies for the connection of the motor.

The special connection regulations are to be observed for explosion-protected models.

Accident prevention

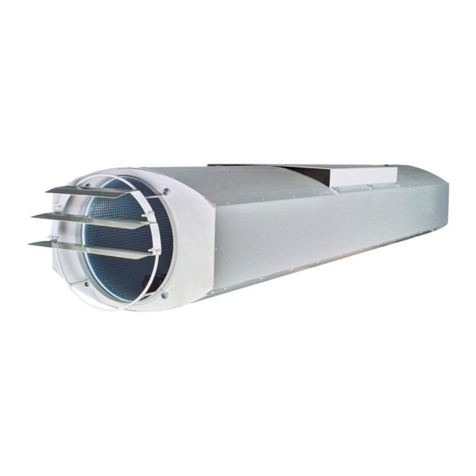

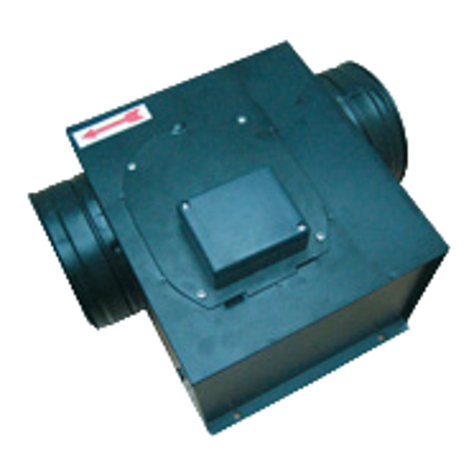

• Protective anti-intrusion ttings, protective screens (see accessories) mounted, fan boxed in or

assembled out of reach.

• If the fan is assembled for free-suction, the suction aperture must be covered by a protective

screen. This is the only way that the accident prevention regulation governing protection from

contact can be deemed to have been met.

13.2 STARTING UP THE FAN FOR THE FIRST TIME

Only put the fan into operation after it has been assembled in accordance with the regulations!

• Prepare fan for rst operation

- correct mechanical installation

- proper tension of the drive belt

- electrical installation in accordance with regulations

- remove foreign matters from inlet and outlet area and from inside of fan

- protection guard ( accessories) installed, no entry to fan or fan being installed out of arm

sweep

Only commence operation when fan is installed in accordance with ordinances!

If the fan is started under free blow conditions, i. e. prior to connecting to duct system,

the current consumption may exceed the rated current (forbidden area of the fan curve)!

Check Impeller.

Check direction of rotation as per direction arrow on the casing by short turning on.

with 3-phase-motor

- to change direction of rotation transpose two of the phases!

with 1-phase-motor

- to change direction of rotation transpose the position of leads as per motor wiring diagram.

- Thermal protection of motor may activate!

• Monitor its correct function (quiet running, vibration, imbalance, power consumption, controllability)

Should the required output (volume ow or pressure increase) not be achieved by the fan,

maximum n settings specied both on the rating plate and in the technical documentation. The

power consumption must be re-measured in order to avoid any possible motor overload.

The thermo-protection system may be activated if the motor power consumption is too high!

• Check the bearing temperature after a lengthy period of operation

Always keep suction openings clear! Check protective screens or protective anti-intrusion ttings

for dirt, and clean if necessary!

13.3 CHECKS AFTER INITIAL START-UP

Check the mechanical connections after initial start-up, especially the joints at the fan.

Observe correct function (smoothness of running, vibration, unbalance current

consumption, possibly controllability, belt drive)

By regular inspection of the fan inlet make sure debris has not collected on the guard and

clean if necessary !

In case of extended periods of standstill, loosen the tension of the drive belt in order to

release the load on the bearing!

14 HELP WITH MALFUNCTIONS

The following points must be observed in order to avoid damage to the machinery or life-threatening injury

when eliminating machine malfunctions:

- Only eliminate any malfunction if you have the specied qualications necessary for the task.

- First of all ensure that the machine cannot be switched on inadvertently, by locking the equipment‘s off

switch or control cabinet by means of a padlock.

- Secure the hazardous area with respect to moving machine parts.

- Read the chapter, "General Safety Notes".

8