4

An ongoing program of product improvement may require us to change

specifications without notice. MH-W-IR

Revised November 2009

Wood Stone Corporation

1801 W. Bakerview Rd.

Bellingham, WA 98226 USA

Toll Free (800) 578-6836

Tel (360) 650-1111

Fax (360) 734-0223

Mountain Series Installation and Operation Manual

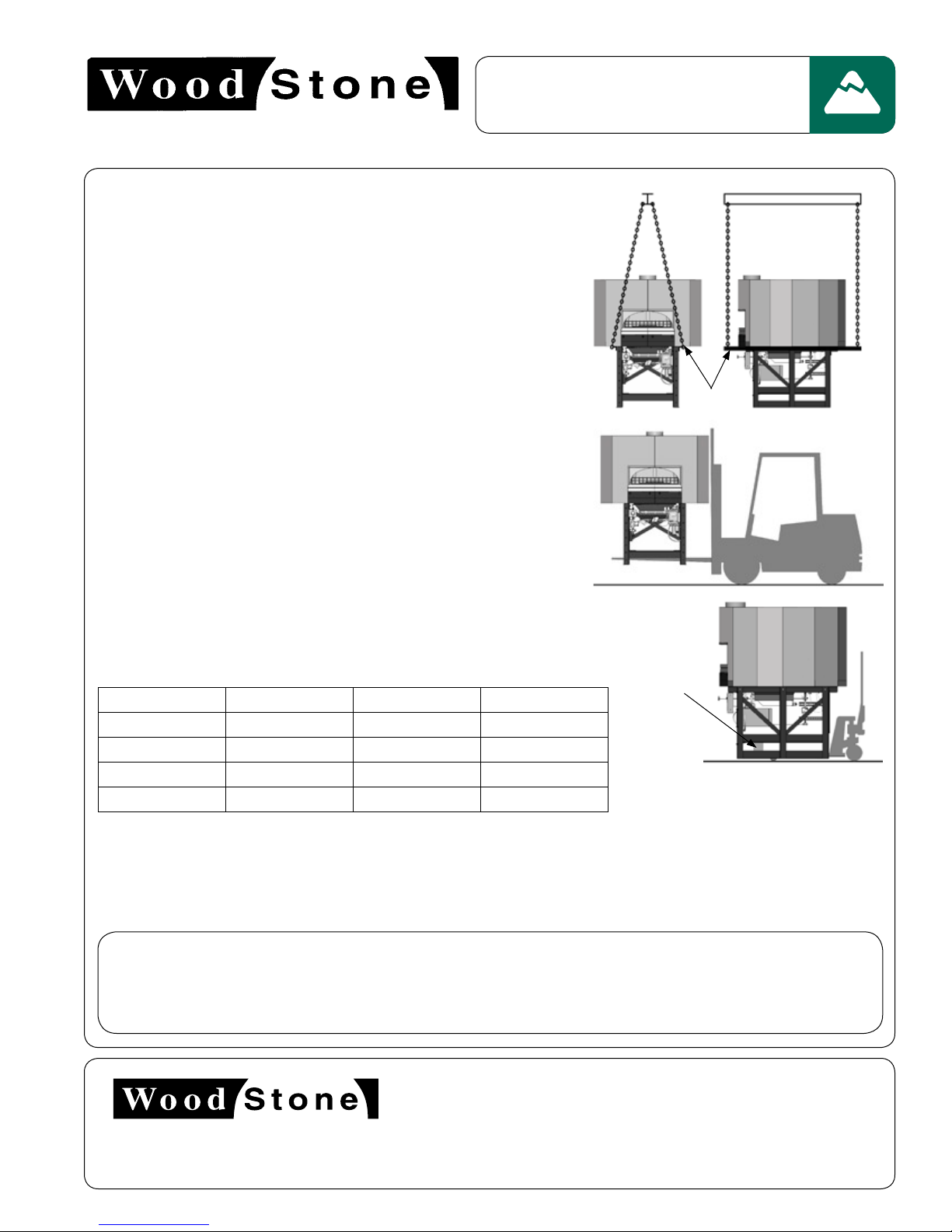

unLoadinG and moVinG

Model # Model Approx. Weight Req’d Forklift

WS-MH-4 Mt. Chuckanut 2,200 lbs. 5,000 lbs.

WS-MH-5 Mt. Adams 3,300 lbs 6,000 lbs.

WS-MH-6 Mt. Baker 4,200 lbs. 6,000 lbs.

WS-MH-7 Mt. Rainier 5,300 lbs. 9,000 lbs.

3. USING A PALLET JACK

Once the appliance has been removed from the delivery vehicle, it can

easily be moved on flat surfaces using a pallet jack. To lift with a pallet

jack, remove the front and rear angle iron stabilizers from the base of

the stand and place a stout 4x4 post through the fork pocket as shown.

THE APPLIANCE IS VERY TOP-HEAVY, MOVING THE APPLIANCE UP OR

DOWN A RAMP ON A PALLET JACK IS NOT SAFE!

Contact Wood Stone if the appliance must be turned on its side for specific instructions. Moving a Wood Stone

appliance can present interesting challenges to even the most experienced riggers. Take your time, use your head, secure

the proper equipment and make safety your first priority. Please don’t hesitate to call the factory for technical support.

DO NOT TURN THE APPLIANCE ON ITS SIDE!

DELIVERY NOTE:The customer will receive a Shipping Notification when the unit leaves the Wood Stone

factory. This will include a PRO# and a trucking company contact number. Wood Stone recommends that you

confirm the delivery date/time with the trucking company before committing to heavy equipment and/or labor.

Our goal is a smooth and safe delivery. Thank you.

2. USING A FORKLIFT

Be sure to use a forklift rated to lift more than the appliance weighs as

shown below. Fork length must be at least 6 feet, if not, fork extensions

should be used. The stand is equipped with fork pockets just above the

angle iron base. The appliance is very top heavy so spread the forks as far

apart as possible.

4x4 post

LIFTING THE APPLIANCE

1. USING A CRANE

The appliance arrives with four lifting eyes attached. When craning use a

spreader bar with a two-legged sling rigged on each end. The spreader

bar should be of a sufficient length to keep the sling from contacting the

appliance.

NOTE: Once lifting eyes are no longer needed, remove the lifting eyes one

at a time AND BE SURE TO REPLACE THE BOLTS THAT ATTACH THE

APPLIANCE TO THE STAND.

Lifting Eyes