Manual 37139C UMT 1 - Measuring Transducer

Page 4/62 © Woodward

Basic Data..............................................................................................................................................

CHAPTER 6. CONFIGURATION................................................................................................. 23

24

Configuration Access............................................................................................................................. 24

Sealing (Until Version 1.9xx) ....................................................................................................... 24

Password (Starting with Version 2.0xx / 3.0xx) ........................................................................... 26

Change Passwords (Starting with Version 2.0xx / 3.0xx)............................................................ 27

Measurement......................................................................................................................................... 28

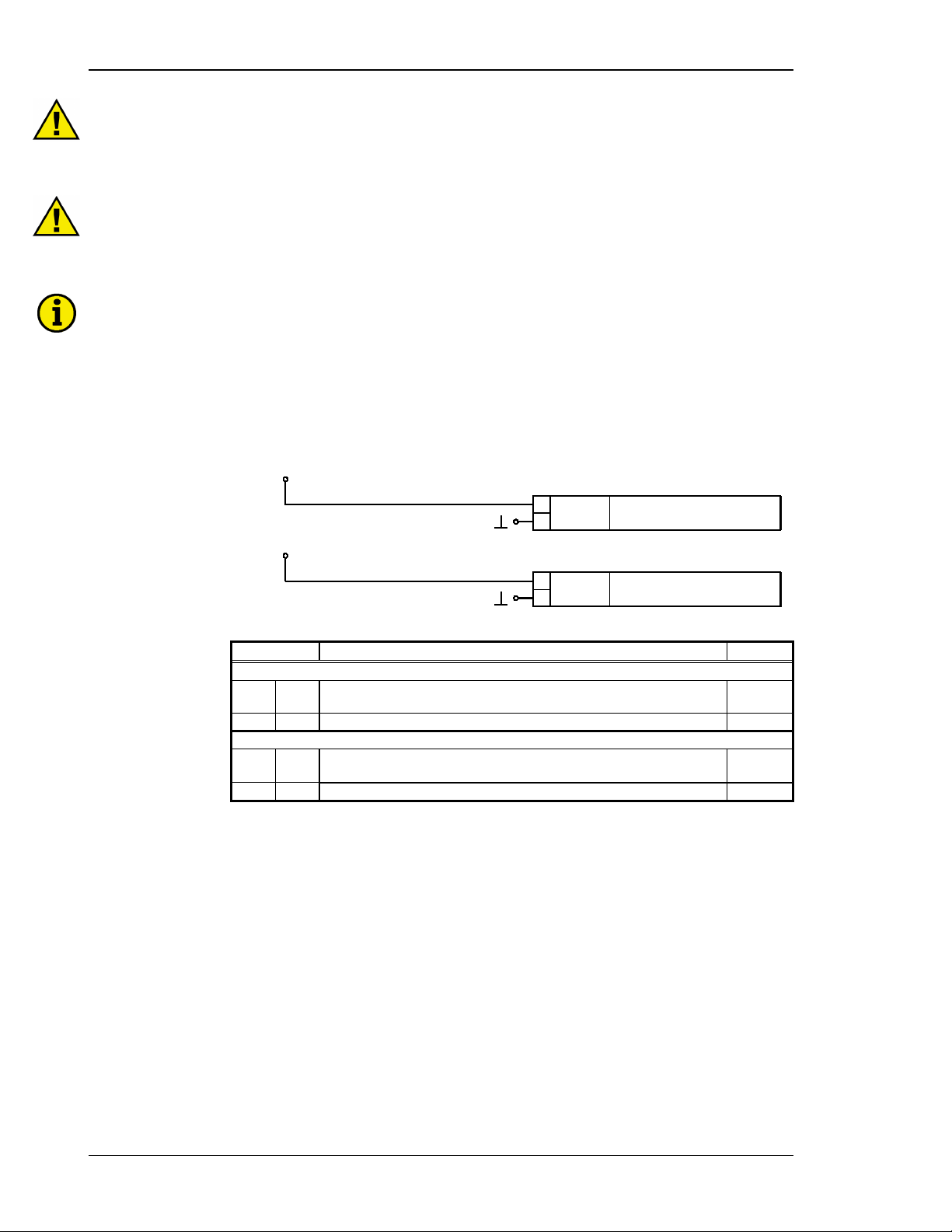

Potential Transformer Configuration ........................................................................................... 28

Current Transformer Configuration ............................................................................................. 28

Measuring System ................................................................................................................................. 29

Pulse Output for Energy Counter........................................................................................................... 29

Screens for "+kvarh" and "-kvarh" Setting ................................................................................... 29

Screens for "+kWh" and "-kWh" Setting...................................................................................... 30

Energy Counter Display............................................................................................................... 30

Common Screens........................................................................................................................ 30

Display Refresh Time .................................................................................................................. 31

Measuring Filter........................................................................................................................... 31

Analog Outputs (Options A1/2/3/4/6/8).................................................................................................. 32

Interface (Option SU)............................................................................................................................. 34

Screens for Protocol DK3964 (Option SU) .................................................................................. 34

Screens for Protocol Profibus DP Slave (Option SU).................................................................. 34

Screens for Protocol Modbus RTU Slave (Option SU)................................................................ 34

Screens for Protocol CAN Bus (Options SU/SB) ........................................................................ 35

CHAPTER 7. COMMISSIONING ................................................................................................. 36

Measuring System 1W...........................................................................................................................

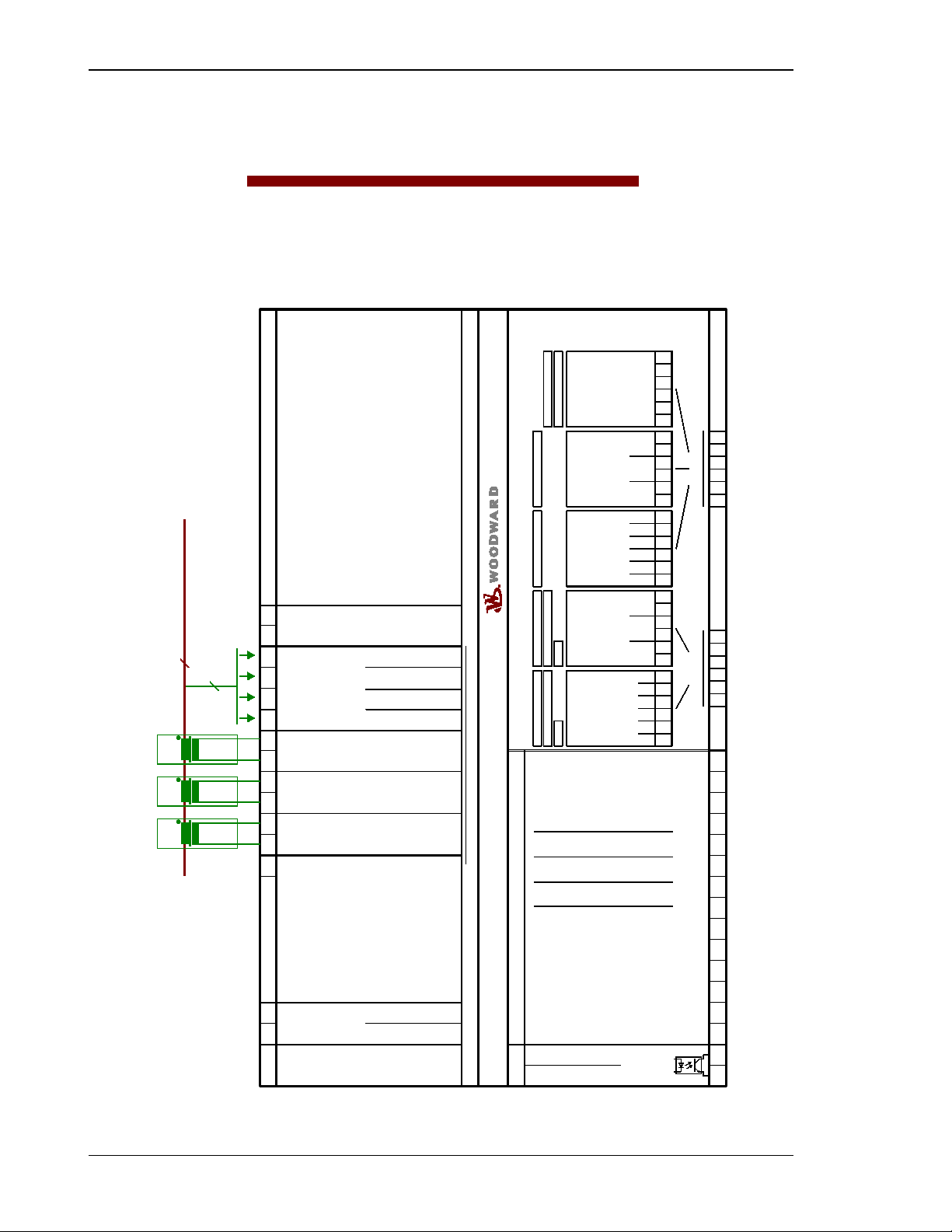

APPENDIX A. MEASURING SYSTEMS ....................................................................................... 38

38

Measuring System 1W4......................................................................................................................... 39

Measuring System 1W3......................................................................................................................... 39

Measuring System 2W3......................................................................................................................... 40

Measuring System 2W4......................................................................................................................... 40

APPENDIX B. DIMENSIONS ..................................................................................................... 41

APPENDIX C. TECHNICAL DATA .............................................................................................. 42

APPENDIX D. MEASURED QUANTITIES AND ACCURACY............................................................ 44

Communication Interface Addresses.....................................................................................................

APPENDIX E. INTERFACE TELEGRAM ...................................................................................... 45

45

Description of the Data Format.............................................................................................................. 48

Examples..................................................................................................................................... 49

Framework Data for the Interfaces ........................................................................................................ 50

Framework Data to Procedure 3964 (TTY, RS-232, RS-485)..................................................... 50

Framework Data for Hardware Handshaking RTS/CTS (RS-232, RS-422)................................ 50

Framework Data for Modbus RTU Slave .................................................................................... 50

Framework Data for CAN Bus..................................................................................................... 51

Framework Data for Profibus DP ................................................................................................ 52

APPENDIX F. LIST OF PARAMETERS........................................................................................ 53

Product Service Options ........................................................................................................................

APPENDIX G. SERVICE OPTIONS ............................................................................................ 57

57

Returning Equipment for Repair ............................................................................................................ 57

Packing a Control ........................................................................................................................ 58

Return Authorization Number RAN ............................................................................................. 58

Replacement Parts ................................................................................................................................ 58

How to Contact Woodward .................................................................................................................... 59

Engineering Services ............................................................................................................................. 60

Technical Assistance ............................................................................................................................. 61