©2018 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. A2X_transducer_im_ RevB_(009-10167)_09-18

A2X EXPLOSION/FLAME PROOF

PRESSURE TRANSDUCER

INSTRUCTION SHEET

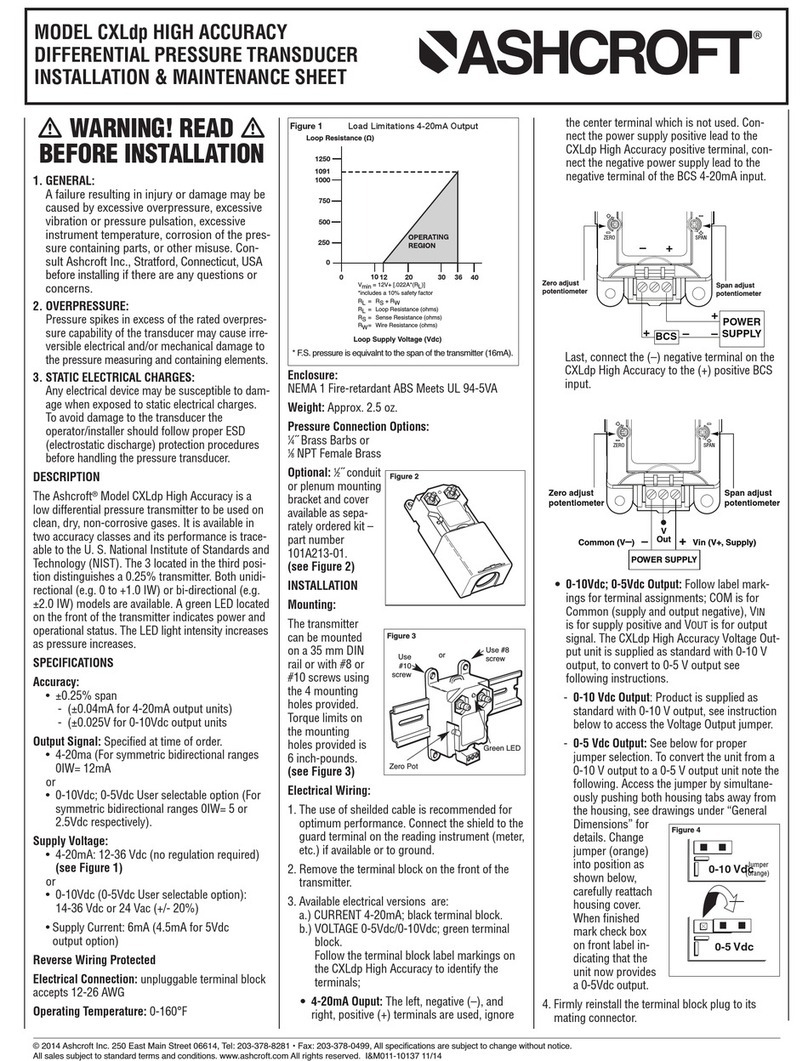

Ashcroft®A2X Pressure Transmitter, Typical Dimensions and Construction*

*Dimensions and construction details may vary based on product specified.

Conduit

electrical

termination

mWARNING! READ m

BEFORE INSTALLATION

1. GENERAL:

A failure resulting in injury or damage

may be caused by excessive overpres-

sure, excessive vibration or pressure

pulsation, excessive instrument tem-

perature, corrosion of the pressure

containing parts, or other misuse.

Consult Ashcroft Inc., Stratford,

Connecticut, USA before installing if

there are any questions or concerns.

2. OVERPRESSURE:

Pressure spikes in excess of the rated

overpressure capability of the transducer

may cause irreversible electrical and/

or mechanical damage to the pressure

measuring and containing elements.

Fluid hammer and surges can destroy

any pressure transducer and must always

be avoided. A pressure snubber should

be installed to eliminate the damaging

hammer effects. Fluid hammer occurs

when a liquid flow is suddenly stopped,

as with quick closing solenoid valves.

Surges occur when flow is suddenly

begun, as when a pump is turned on at

full power or a valve is quickly opened.

Liquid surges are particularly damaging

to pressure transducers if the pipe is orig-

inally empty. To avoid damaging surges,

fluid lines should remain full (if possible),

pumps should be brought up to power

.887˝

4.78˝

3.065˝

.675˝

1.06˝

DIA.

.887˝

4.78˝

3.065˝

.885˝ 1.06˝ (27) Hex.

Common For All

Pressure Fittings

(22.5)

(121)

(78)

(17)

(27)

.887˝

4.78˝

3.065˝

.675˝

1.06˝

DIA.

.887˝

4.78˝

3.065˝

.885˝ 1.06˝ (27) Hex.

Common For All

Pressure Fittings

(22)

(78)

(121)

(22.5)

1.06˝

DIA.

(27)

slowly, and valves opened slowly. To

avoid damage from both fluid hammer

and surges, a surge chamber should be

installed.

Symptoms of fluid hammer and surge’s

damaging effects:

• Pressure transducer exhibits an output

at zero pressure (large zero offset).

• Pressure transducer output remains

constant regardless of pressure

• In severe cases, there will be no output.

FREEZING:

Prohibit freezing of media in pressure

port. Unit should be drained (mount in

vertical position with electrical termina-

tion upward) to prevent possible over-

pressure damage from frozen media.

3. STATIC ELECTRICAL CHARGES:

Any electrical device may be susceptible

to damage when exposed to static elec-

trical charges. To avoid damage to the

transducer observe the following:

• Operator/installer should follow the

proper ESD (electrostatic discharge)

protection procedures before handling

the pressure transducer.

• Ground the body of the transducer

BEFORE making any electrical

connections

• When disconnecting, remove the

ground LAST!

Note: The shield and drain wire in the

cable (if supplied) is not connected to

the transducer body, and is not a suitable

ground.

4. WARNING/AVERTISSEMENT

• DO NOT OPEN UNIT WHEN

ENERGIZED

NE PAS OUVRIR L’APPAREIL

LORSQU’IL EST SOUS TENSION

• SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY

LA SUBSTITUTION DE COMPOSANTS

PEUT COMPROMETTRE LA

SÉCURITÉ INTRINSÈQUE”

• EXPLOSION HAZARD - DO NOT

DISCONNECT WHILE CIRCUIT IS

LIVE UNLESS AREA IS KNOWN TO

BE NON-HAZARDOUS

RISQUE D’EXPLOSION. NE PAS

DÉBRANCHER TANT QUE LE

CIRCUIT EST SOUS TENSION, À

MOINS QU’lL NE S’AGISSE D’UN

EMPLACEMENT NON DANGEREUX

• EXPLOSION HAZARD –

SUBSTITUTION OF COMPONENTS

MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2

RISQUE D’EXPLOSION – LA

SUBSTITUTION DE COMPOSANTS

PEUT RENDRE CE MATÉRIEL

INACCEPTABLE POUR LES

EMPLACEMENTS DE CLASSE I,

DIVISION 2