SIAP+MICROS t027 TP200 Guide

t027 TP200

Precipitation Transducer, collecting area 200 cm²

User Manual and maintenance

User manual and maintenance

t027-di TP200.docx

27/10/2023 2Vers.: 1.0

Summary

1Introduction ................................................................................................................................................ 3

2Technical specificaion ................................................................................................................................ 4

3Installation and maintenance ..................................................................................................................... 6

3.1 Installation.......................................................................................................................................... 6

3.2 Maintenance ...................................................................................................................................... 6

4Electrical connection.................................................................................................................................. 7

4.1 Connector output ............................................................................................................................... 7

4.2 Connection cable ............................................................................................................................... 7

4.3 Data reading in serial (RS485 Modbus and SDI-12) ......................................................................... 7

4.3.1 RS485 Modbus mode .................................................................................................................... 7

4.3.2 SDI-12 mode.................................................................................................................................. 8

5Generic information ................................................................................................................................... 9

5.1 Safety................................................................................................................................................. 9

5.2 Appropriate use of the equipment ................................................................................................... 10

5.3 Storage ............................................................................................................................................ 10

5.4 Moving ............................................................................................................................................. 10

5.5 Disposal information ........................................................................................................................ 10

6Revision history ........................................................................................................................................11

User manual and maintenance

t027-di TP200.docx

27/10/2023 3Vers.: 1.0

1Introduction

TP200 is a tipping bucket rain gauge with a collecting area of 200 cm². It is extremely precise, very performant

and suitable also for environments where heavy rainfalls easily occur (monsoon or tropical rains). The tipping

bucket consists of a v-shaped element, particularly designed to minimize friction and facilitate the oscillating

action of the bucket, ensuring high standards of accuracy. The body is made of aluminium alloy and painted

with a special anti-UV paint which ensures long-lasting quality and resistance to the weather events. The

TP200 can be supplied in three different versions: TP200-N with impulse/reed contact output, TP200-E and

TP200- 12, both equipped with a specific signal conditioning electronics that reduces measurement

uncertainties at high intensities of precipitation (both for intensity and amount values). TP200-E version

equipped with electronic correction can give on a single connector the reed contact output (rainfall amount),

the current output (intensity) and the Modbus serial output (both intensity and amount). TP200-12 version is

similar to the TP200-E but it has been designed on purpose to have the SDI-12 standard communication

protocol instead of Modbus. TP200-N is also available on heated version, powered at 24V (alternating or direct

current). In every version, the sensor is supplied with power and signal cable (12m).

Ordering Codes:

Reed contact output:...............................................................................t027a TP200-N

Heated version, Reed contact output: ....................................................t028a TP200R-N

Version with electronic correction ...........................................................t027q TP200-E

Available outputs: reed contact, current (or voltage), RS-485 Modbus

Version with electronic correction. ..........................................................t027r TP200-12

Available outputs: reed contact, current (or voltage), SDI-12

User manual and maintenance

t027-di TP200.docx

27/10/2023 4Vers.: 1.0

2Technical specificaion

Measurement performance

Collecting area

200 cm2

Conversion constant

0.2 mm/impulse

Amount resolution

0.2 mm

Intensity resolution (TP200-E and -12)

0.1 mm/h

Amount range

0 ÷ ∞ mm

Intensity range (TP200-E and -12)

0 ÷ 500 mm/h

Amount accuracy (-N)

± 2 % @ 10 ÷ 70 mm/h

± 5 % @ 70 ÷ 150 mm/h

± 7 % @ 150 ÷ 200 mm/h

± 10 % @ 200 ÷ 300 mm/h

Amount accuracy (TP200-E and -12)

± 2 % @ < 300 mm/h,

Intensity accuracy (TP200-E and -12)

± 2 % @ < 300 mm/h,

Operating conditions

Temperature

0 ÷ 70 °C

Temperature (heated version)

-20 ÷ 70 °C

Rainfall intensity

0 ÷ 500 mm/h

Output

Contatto reed

0.2 mm/impulse

RS-485 Modbus / SDI-12

Raw amount [mm], Adjusted intensity [mm/h],

Adjusted amount [mm]

Tension

0 ÷ 2 V ↔0 ÷ 500 mm/h

Current

4 ÷ 20 mA ↔0 ÷ 500 mm/h

Power supply and Consumption

Voltage supply

7 ÷ 30 Vdc

Heating system voltage supply (if present)

12 ÷ 24 V (DC o AC)

Power consumption

Min

Tipico

Massimo

RS-485 Modbus / SDI-12 / 0÷2 V

1

3

4÷20 mA

5

25

Mechanical specifications

Protective body

Aluminium alloy, stainless steel screws

Trim

Thermosetting polyester-based powder paint,

RAL 9003

Electrical connections

IP67 / 7 pole male connector

User manual and maintenance

t027-di TP200.docx

27/10/2023 5Vers.: 1.0

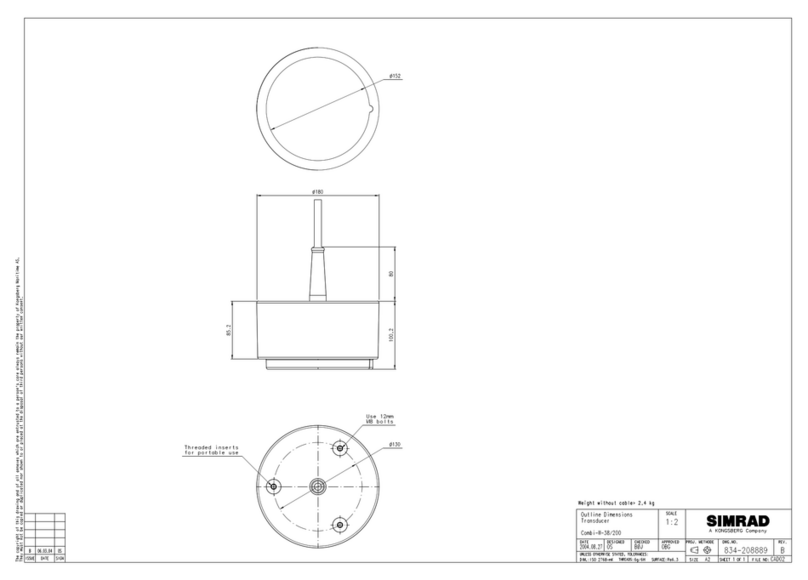

Dimension:

H - height: 345 mm

D - diameter: 165 mm

Element:

B – mouth calibrated 200 cm²

F1 – input filter

F2 – exhaust filter

GB – action group

E – management electronics (TP200

with non-natural output)

G – support shank

Weight: 2,2 kg

User manual and maintenance

t027-di TP200.docx

27/10/2023 6Vers.: 1.0

3Installation and maintenance

3.1 Installation

When installing a meteorological station, it is necessary to pay attention

to the characteristics of the place as the conformation of the land and the

proximity to any obstacles can affect the quality of the data that will be

collected. In particular, it must be kept in mind that any vertical obstacle

such as trees and buildings create an air turbulence equal to ten times

their height. For this reason, by way of example, a weather station must

maintain a minimum distance of 100 meters from 10 meter high

obstacles.

The rain gauges of the TP200 family must be installed according to WMO

standards, with the precipitate collection mouth at 2 metres. For their

installation, two types of poles are typically used, one for burying and

supported by a foundation plinth or one with a base for installation on

slabs, terraces, etc.

The electrical connection is made through the cable to the connector (A)

located on the lower part of the rain gauge. Mechanically, the rain gauge

is installed by positioning it on the top of the support pole (ø70mm)

without the upper part, cone and mouth, which can be removed by

unscrewing the 3 side fixing screws (C). Subsequently, insert the rain

gauge on the pole and fix it by tightening the 6 screws on the base (B),

the same screws are also used to check the horizontality of the calibrated

mouth of the rain gauge by checking the leveling with the spirit level inside (D).

Before putting the rain gauge into operation, remember to "release" the rocker from its locking elastic.

3.2 Maintenance

When using the TP200 rain gauges, it is necessary to pay attention to keeping the upper inlet clean to prevent

any bodies from obstructing the passage of water, compromising its operation. Indeed dust, leaves, etc. can

reduce the flow capacity of the water through the duct that leads to the oscillating bucket. It is advisable to

clean the upper cone, the filter present on it and the one on the lower part, in pre-established periods with

clean water, unscrewing it from the body of the rain gauge. Finally, it is advisable to clean the nozzle located

immediately above the measuring scale with a brush.

User manual and maintenance

t027-di TP200.docx

27/10/2023 7Vers.: 1.0

4Electrical connection

4.1 Connector output

Pin

TP200-N

TP200-E

TP200-12

1

Contact

Contact

Contact

2

Contact

Contact

Contact

3

n.c.

A-RS485

SDI-12 (data)

4

n.c.

B-RS485

n.c.

5

n.c.

+4÷20 mA

(o +0÷2 Vdc)

+4÷20 mA

(o +0÷2 Vdc)

6

n.c.

Vcc

Vcc

7

n.c.

GND

GND

4.2 Connection cable

The connection cable supplied with the sensor is made with circular connectors with housing, shielded

8x0.22mmq cable and ferrules for connection to the data logger terminals. The shield is connected to the black

cable.

Pin

1

2

3

4

5

6

7

7

Cable

Red

White

Green

Black

Orange

Yellow

Blue

Brown

TP200-N

Contact

Contact

n.c.

n.c.

n.c.

n.c.

n.c.

n.c.

TP200-E

Contact

Contact

A-RS485

B-RS485

+4÷20 mA

(o +0÷2 Vdc)

Vcc

GND

GND

TP200-12

Contact

Contact

SDI-12

(data)

n.c.

+4÷20 mA

(o +0÷2 Vdc)

Vcc

GND

GND

4.3 Data reading in serial (RS485 Modbus and SDI-12)

Sensors with RS485 Modbus or SDI-12 output send data only upon specific request from the PC, data logger

or PLC.

Below are the correct communication parameters of the device performing the interrogation.

4.3.1 RS485 Modbus mode

Serial port settings: 9600 baud, no parity, 8 data bit, 1 bit di stop

Compatible with ModBus RTU protocol, functions supported: “03 – read Holding Registers” e “04 – Read Input

Registers”.

Data type: “2 registers swapped float IEEE 754 in the form CDAB where A is the most significant byte of the

float and D is the less significant byte of the float (swapped float)”.

User manual and maintenance

t027-di TP200.docx

27/10/2023 8Vers.: 1.0

ID

Registers

Units

Reg. 1-2

Reg. 3-4

Reg. 5-6

Reg. 7-8

Reg. 9-10

Reg. 11-12

Reg. 13-14

17

1

mm

Total amount

of rain

Rain

intensity

Correct

total

amount of

rain for

intensity

Diagnostic

Supply Voltage

3

mm/h

5

mm

4.3.2 SDI-12 mode

Serial port settings: 1200 baud, even parity, 7 data bits, 1 stop bit

?! Address Query

aI! Send Identification

aM! Start Measurement

aC! Start Concurrent Measurement

aD0! Send Data

a

Position

Units

Decimals

Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Position 7

H

1

mm

3

Total

amount of

rain

Rain

intensity

Correct

total

amount of

rain for

intensity

Diagnostic

Supply

Voltage

2

mm/h

3

mm

User manual and maintenance

t027-di TP200.docx

27/10/2023 9Vers.: 1.0

5Generic information

The qualitative level of our instruments is the result of a continuous evolution of the product. This may cause

differences between what is reported in the manual and the instrument you have purchased.

Siap+Micros S.p.A. reserves the right to modify without notice technical specifications and dimensions to adapt

them to the needs of the product.

5.1 Safety

Please read these safety instructions carefully before using this product:

•The warranty will be void if the product is used differently from the instructions described in this manual.

•Any sign of tampering will void the warranty

•Use the devices only according to the instructions (environmental management, operation, wiring,

installation, etc.) provided in this manual

•The correct and safe operation of the device can only be guaranteed if the transport, storage, operation

and management of the device are compliant. This also applies to product maintenance.

•The device shall not be exposed to aggressive chemicals or solvents that could damage the plastic

casing and/or corrode the metal parts.

•Maintenance should only be performed by qualified and well trained personnel.

It is appropriate to carry out a careful risk assessment in relation to the context of installation and use of the

device by the installer considering the possible meteorological station in its complexity without being limited to

the sensor.

The instruments must be installed according to the rules of the trade, with equipment that complies with

applicable regulations and using supports correctly sized by qualified technicians and designed for the specific

purpose.

During installation operations, check the suitability of the surrounding environment and compliance with local

safety regulations.

The manufacturer declines all responsibility in case of failure due to negligence of the instructions, tampering,

uses not described in this manual, improper use, use by operators not trained.

Read the instructions and intended use carefully and be sure you understand before installing the device

Before starting the activities, check the integrity of the instrument to be installed, prepare the equipment

necessary for the work and wear the necessary PPE.

Take adequate measures to prevent the access of foreign personnel (untrained and uninformed) during the

installation, maintenance or replacement of the instrument.

Take precautions to avoid falling objects, both during the installation phases and during the operation of the

instrument.

Do not perform any activity in bad weather conditions.

User manual and maintenance

t027-di TP200.docx

27/10/2023 10 Vers.: 1.0

During maintenance, particularly if the station is not frequented, visually check for the absence of dangerous

insects and, if not, use suitable insecticides.

Consider the presence of any animals near the station, if so, pay attention to them.

Use only SIAP+MICROS original spare parts.

The instrument is not classified suitable (according to Directive 2014/34/EU) for use in atmospheres with

potential explosion risk pursuant to Directive 99/92/EC.

SIAP+MICROS strives to minimize health and safety risks in all phases of the instrument's life, including

installation, use, maintenance, decommissioning and disposal.

5.2 Appropriate use of the equipment

Use the instrument for its intended purpose, do not use it for any other purpose or cause malfunctions and/or

damage.

5.3 Storage

If you do not plan to use the equipment for an extended period of time (at least one year) disconnect all cables

from the equipment, place it in a clear plastic bag along with a bag of desiccant salts and seal the bag with

tape. Put appropriate indication on the bag of the contents and weight of the equipment by inserting the wording

"HANDLE WITH CARE".

Store the instrument in an environment with a temperature between 0°C and 60°C with a humidity not

exceeding 80%. Make sure that the instrument is stored in a stable position and that it cannot be damaged or

moved by inexperience or carelessness. Do not stack other tools or weights. Do not place the instrument on

top of other instruments and in any case ensure the solidity and stability of the underlying support.

Non esporre, stoccare lo strumento in ambienti con presenza di vapori e/o gas corrosivi.

5.4 Moving

In order to avoid any damage to the device during transportation, please keep it in upright position without

shaking.

5.5 Disposal information

Electrical and electronic equipment marked with specific symbol in compliance with 2012/19/EU

Directive must be disposed of separately from household waste. European users can hand them

over to the dealer or to the manufacturer when purchasing a new electrical and electronic

equipment, or to a WEEE collection point designated by local authorities. Illegal disposal is

punished by law.

Disposing of electrical and electronic equipment separately from normal waste helps to preserve natural

resources and allows materials to be recycled in an environmentally friendly way without risks to human health.

User manual and maintenance

t027-di TP200.docx

27/10/2023 11 Vers.: 1.0

6Revision history

The following table shows the description of the changes made to this document.

Version

Date

Updates

1.0

05/06/2023

Current version of the document.

All the information content in this document are the current available at the printing phase. Siap+Micros S.p.A. reserve the rights to change

the specifications without any advance notice

This manual suits for next models

3

Table of contents

Other SIAP+MICROS Transducer manuals

SIAP+MICROS

SIAP+MICROS t012 TTS Guide

SIAP+MICROS

SIAP+MICROS t018 TTP Guide

SIAP+MICROS

SIAP+MICROS t001 TTEP Guide

SIAP+MICROS

SIAP+MICROS t055 TPIR Guide

SIAP+MICROS

SIAP+MICROS t002 TTT Guide

SIAP+MICROS

SIAP+MICROS t003 TRH Guide

SIAP+MICROS

SIAP+MICROS t018 TTP Guide

SIAP+MICROS

SIAP+MICROS t031 TVV Guide

SIAP+MICROS

SIAP+MICROS t031 TVV Guide

SIAP+MICROS

SIAP+MICROS t020 TTA Guide