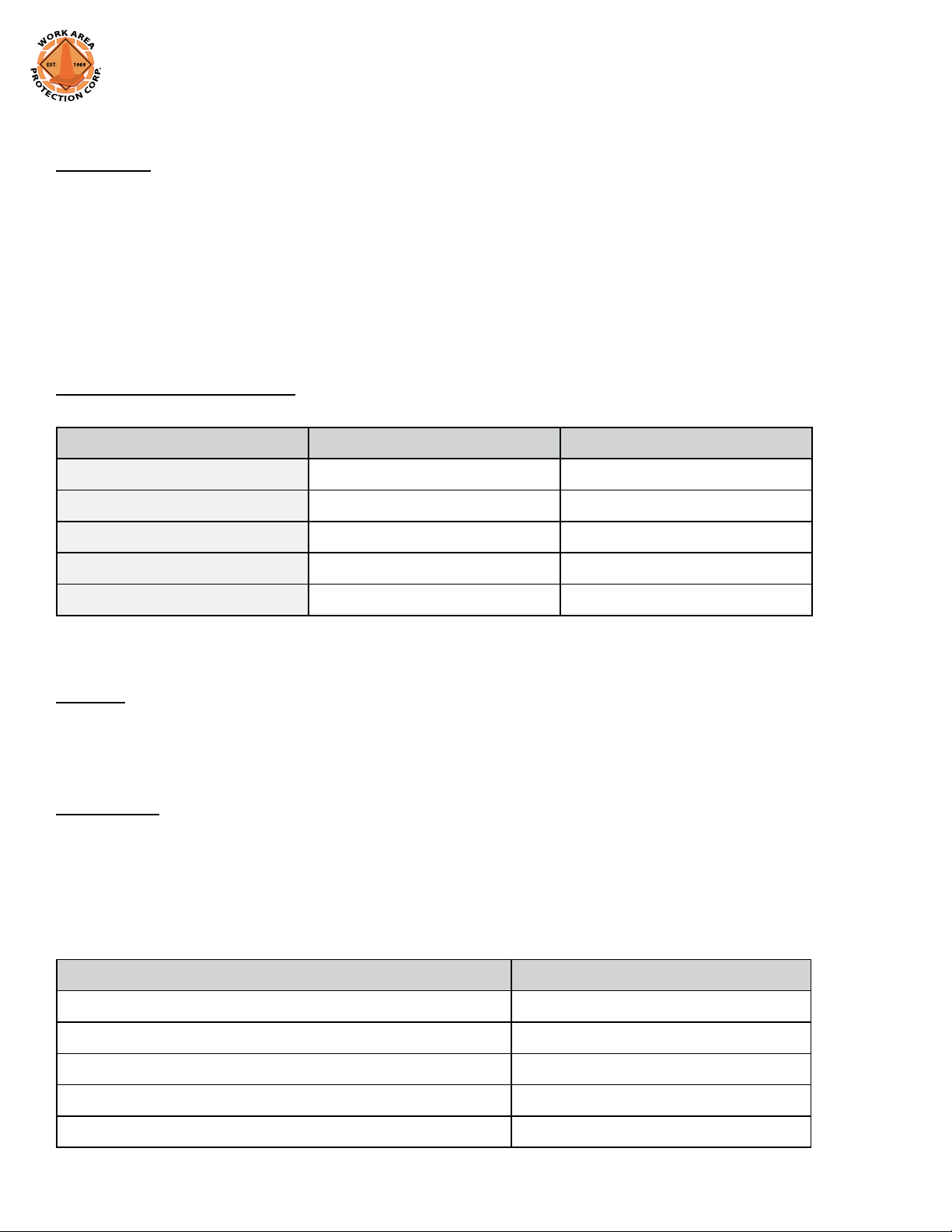

TABLE OF CONTENTS

OVERVIEW ...........................................................................1

Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Maintenance ........................................................................................1

Crash Performance ....................................................................................1

SPECIFICATIONS ......................................................................2

Description ..........................................................................................2

System Dimensions & Weight ...........................................................................2

DESIGN CRITERIA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

General.............................................................................................2

Foundations .........................................................................................2

Support Structure .....................................................................................3

Location ............................................................................................3

Transition Design .....................................................................................4

Drawing List .........................................................................................5

INSTALLATION......................................................................6-9

Installation & Performance Statements ....................................................................6

Safety ..............................................................................................6

Equipment List ...............................................................................Appendix B

Site Preparation ......................................................................................6

Foundations .........................................................................................6

Placement of Crash Cushion.............................................................................7

Anchor Installation ....................................................................................7

Delineator Panel Attachment ............................................................................8

Transition Installation..................................................................................8

Final Inspection ......................................................................................9

RESETTING CRASH CUSHION AFTER IMPACT ..........................................9-13

Site Preparation ......................................................................................9

Re-Extension & Inspection After Frontal Impact............................................................9-10

Side Impact Inspection & Repair ........................................................................11

Cable Inspection Procedure ............................................................................11

Cylinder Inspection...................................................................................12

Anchor Bolt Inspection ................................................................................12

Side Panel Inspection .................................................................................12

Side Guide Inspection.................................................................................12

Final Inspection .....................................................................................13

Non-Repairable Impacts...............................................................................13

Periodic Maintenance.................................................................................13