2

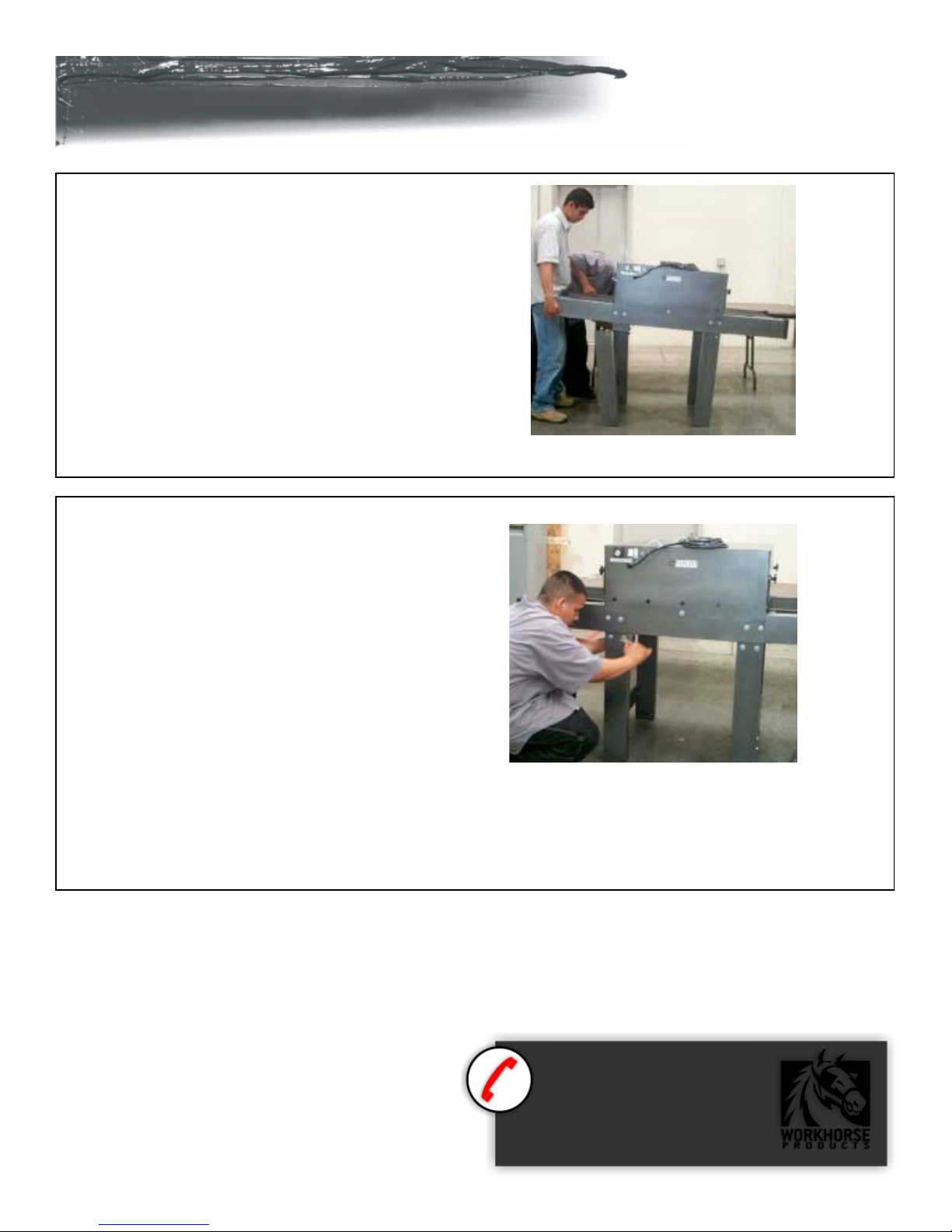

Congratulaons on your purchase of

the Workhorse Products Mercury

Compact Dryer.

Check the crate for damage, DO NOT

accept the crate if damaged due to

improper handling during shipping.

Report any damage to the carrier at

once as well as Workhorse Products at

800-778-8779.

Inspect the crate contents

IMMEDIATELY while the carrier is sll

there. Our packaging has been

carefully designed to handle normal

shipping condions. However, we

cannot be responsible for damage by

the carrier. Upon rst sight of freight

damage nofy or point out to the

driver and le your claim with the

carrier, then nofy us.

Features:

• 2300 WATTS OF POWER – The 30” heat chamber contains an 18”x20” infrared heat panel producing 2300 WATTS of power.

• Compact Size – The MECURY INFRARED COMPACT CONVEYOR DRYERS are compact enough to t almost anywhere having a foot

print of 32” (12.6cm) x 66” (26cm). It is ideal to use as a portable Dryer for those “on site” prinng jobs.

• Air Cooled Hood – The MECURY INFRARED COMPACT CONVEYOR DRYER features improved air ow to keep the hood cool.

• Adjustable Chamber Openings – Sliding doors at the entrance and exit of the heat chamber improve heat stability for consistent

curing temperatures.

• Exhaust Ring – an external ring on top of the dryer allows hook up to a standard duct size to vent the dryer externally.

Questions? Give us a call!

800.778.8779

workhorseproducts.com

Visit our website at

The Workhorse MECURY INFRARED COMPACT CONVEYOR DRYER oers the space saving and power requirements needed for a

small shop. While economically priced it provides faster producon then just a spot dryer. The 115 volt unit is supplied with a

NEMA L530 125V plug and requires a 30 AMP dedicated circuit. The 220 volt unit is supplied with a NEMA 6-15 250 volt plug and

requires a 20 Amp dedicated circuit.

Introduction