15

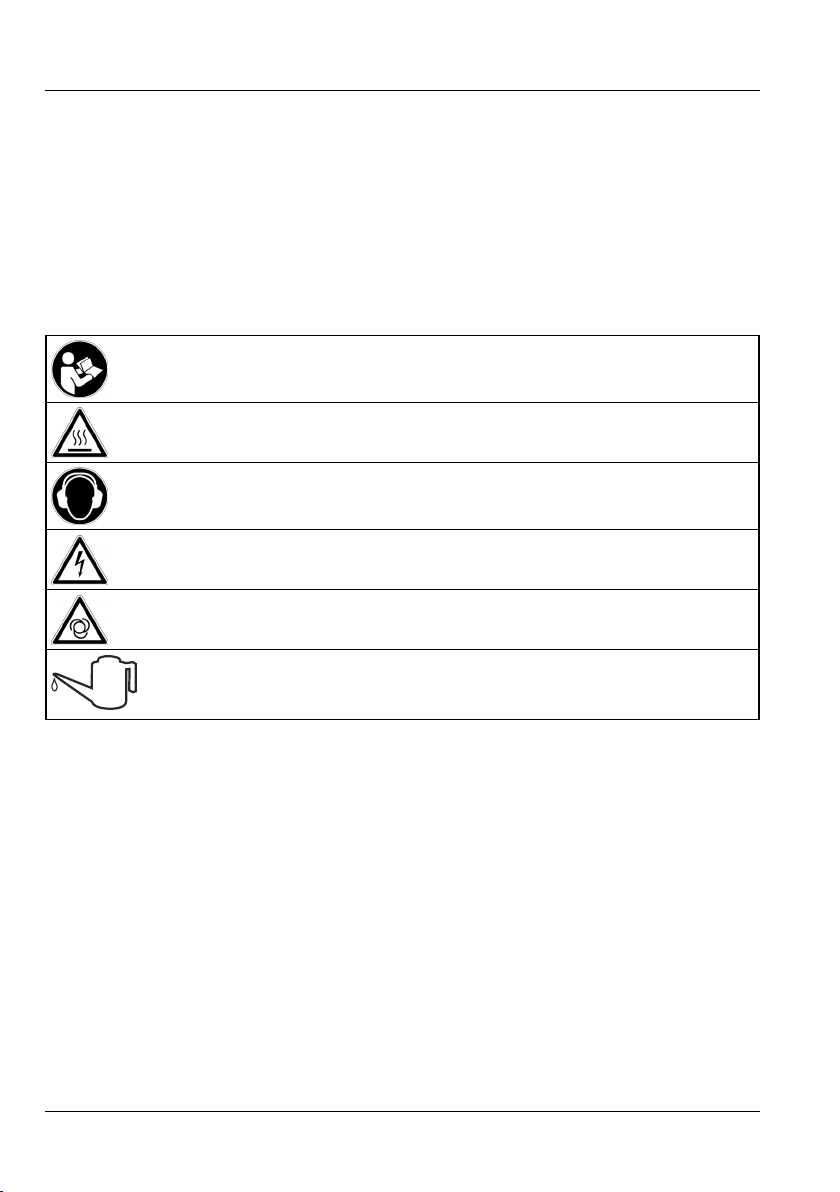

Safety informaon

ADDITIONAL SAFETY INSTRUCTIONS

Safety instrucons for working with compressed air and blasng guns

• The compressor pump and lines can become very hot during operaon. Touching

these parts will burn you.

• The air which is sucked in by the compressor must be kept free of impuries that

could cause res or explosions in the compressor pump.

• When releasing the hose coupling, hold the hose coupling piece with your hand.

This way, you can protect yourself against injury from the rebounding hose.

• Wear safety goggles when working with the blow-out pistol. Foreign bodies or

blown o parts can easily cause injuries.

• Do not blow at people with the blow-out pistol and do not clean clothes while

being worn. Risk of injury!

Safety informaon for paint spraying

• Do not process any paints or solvents with a ash point below 55° C.

There is a risk of explosion!

• Do not heat up paints or solvents. There is a risk of explosion!

• If hazardous liquids are processed, wear protecve lter units (face guards). Also,

adhere to the safety informaon provided by the manufacturers of such liquids.

• The details and designaons of the Ordinance on Hazardous Substances, which are

displayed on the outer packaging of the processed material, must be observed.

• Addional protecve measures are to be undertaken if necessary, parcularly the

wearing of suitable clothing and masks.

• Do not smoke during the spraying process and/or in the work area.

There is a risk of explosion! Paint vapors are easily combusble.

• Never set up or operate the equipment in the vicinity of a re place, open lights or

sparking machines.

• Do not store or eat food and drink in the work area. Paint vapors are harmful to

your health.

• The work area must exceed 30 m3 and sucient venlaon must be ensured

during spraying and drying. Do not spray against the wind. Always adhere to the

regulaons of the local police authority when spraying combusble or hazardous

materials.

• Do not process media such as white spirit, butyl alcohol and methylene chloride

with the PVC pressure hose. These media will destroy the pressure hose.