Workzone WWPBS-18 User manual

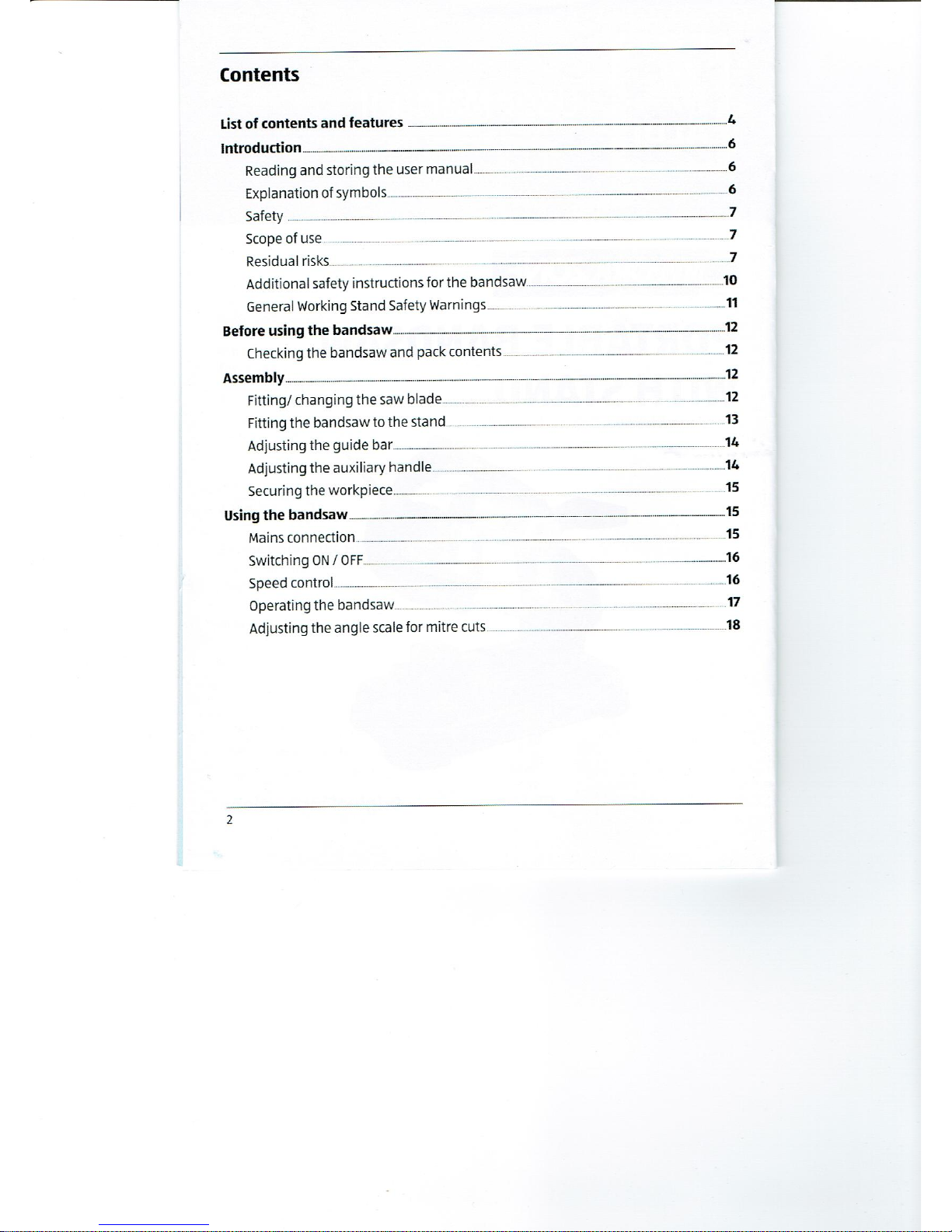

Table of contents

Other Workzone Saw manuals

Workzone

Workzone WZTS 1702 User manual

Workzone

Workzone SD1600V User manual

Workzone

Workzone 50450 User manual

Workzone

Workzone M1Y-DU10-190 User manual

Workzone

Workzone CDY190FLA2 User manual

Workzone

Workzone 55903 User manual

Workzone

Workzone WZTS 1701 User manual

Workzone

Workzone Titanium CS20V User manual

Workzone

Workzone WZTS 1700 User manual

Popular Saw manuals by other brands

Chicago Electric

Chicago Electric Professional Series 60608 Owners manual & safety manual

Meec tools

Meec tools 242-127 operating instructions

Kärcher

Kärcher MT CS 250/36 operating instructions

Fieldmann

Fieldmann FDK 2002-E instruction manual

Altocraft

Altocraft J1X-KZ18-255 Operator's manual

Bosch

Bosch GKS Professional 85 Original instructions

SteelMax

SteelMax S-7 XP Operator's manual

Husqvarna

Husqvarna 357XPG E-tech Workshop manual

Drill Master

Drill Master 93827 Assembly and operating instructions

Ryobi

Ryobi RRS1200-K Original instructions

Metabo

Metabo KGS 303 PLUS Original operating instructions

Jet

Jet JWBS-140S Operating instructions and parts manual