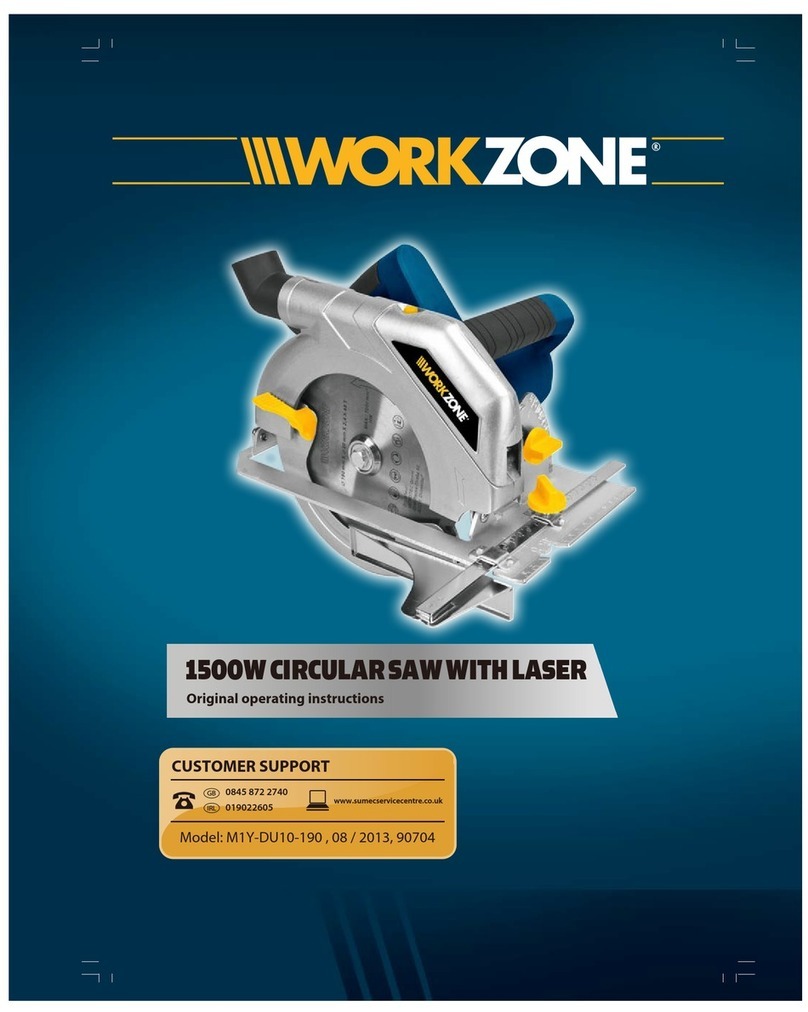

Workzone 50450 User manual

USA 1800 505 8311 acs@americancustomerservice.com

PRODUCT CODE: 50450 06/2016

2

AFTER SALES SUPPORT • SERVICIO POSVENTA

DISTRIBUTED BY • DISTRIBUIDO POR:

ALDI INC.

BATAVIA, IL 60510

www.aldi.us

User Guide

Manual

del usuario

YEAR WARRANTY

AÑOS DE GARANTÍA

English... Page 2

Español... Página 13

13AMP 7-1/4IN. CIRCULAR SAW

SIERRA CIRCULAR DE 7 1/4 PULG. Y 13 A

Contents

Overview ....................................................................................... 3

General Specication ............................................................ 3

Pack Content ........................................................................ 3

Operation& Electrical Safety ........................................................ 4

Changing Blade .................................................................... 4

Adjusting The Bevel Angle .................................................... 5

Using The Parallel Fence ...................................................... 6

Using The Laser Guide ......................................................... 6

Power Tool Use & Care ................................................................ 7-8

Making A Cut ....................................................................... 7

Kickback .............................................................................. 7-8

Safety Warning .................................................................... 8-13

Additional Safety Instructions ............................................... 13

Symbols & Warning ...................................................................... 14

Symbols ............................................................................... 14

Warning ............................................................................... 15

Warranty ....................................................................................... 15

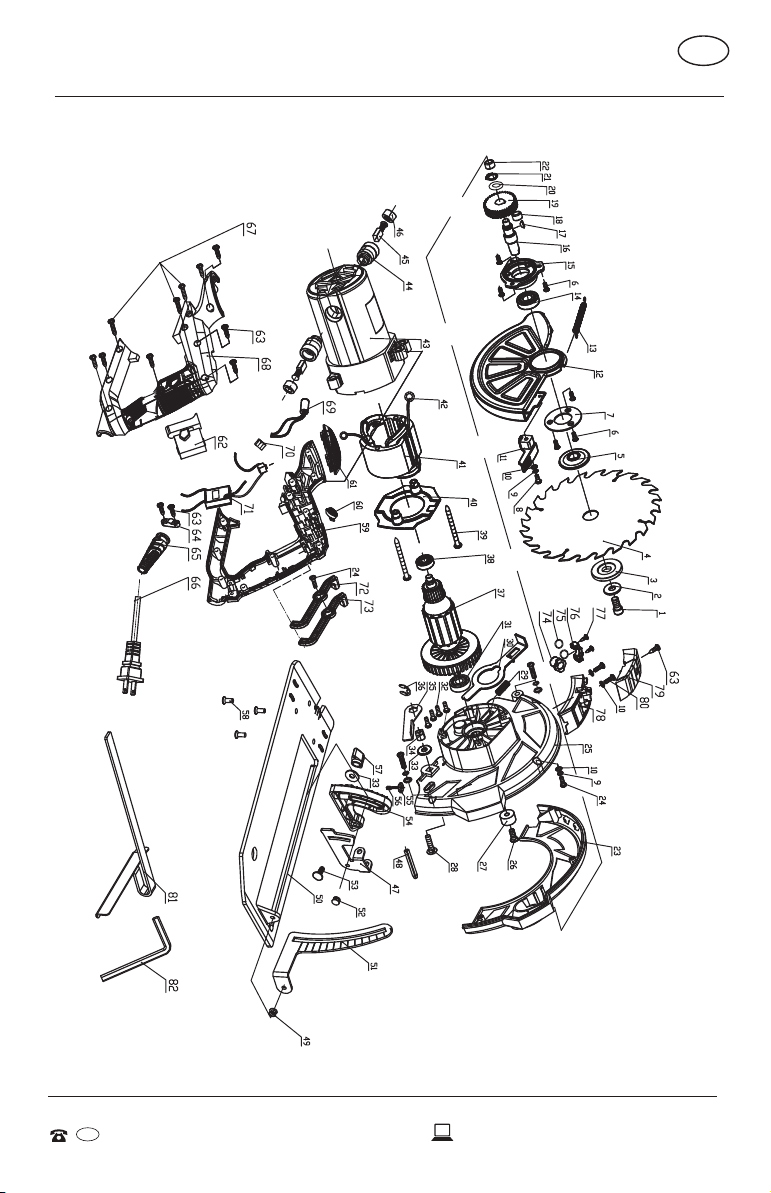

Explosive View & part list ..........................................................16-17

Warranty Card ............................................................................ 34

Warranty Conditions .................................................................. 35

Overview & Pack Content/ Specification

3

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

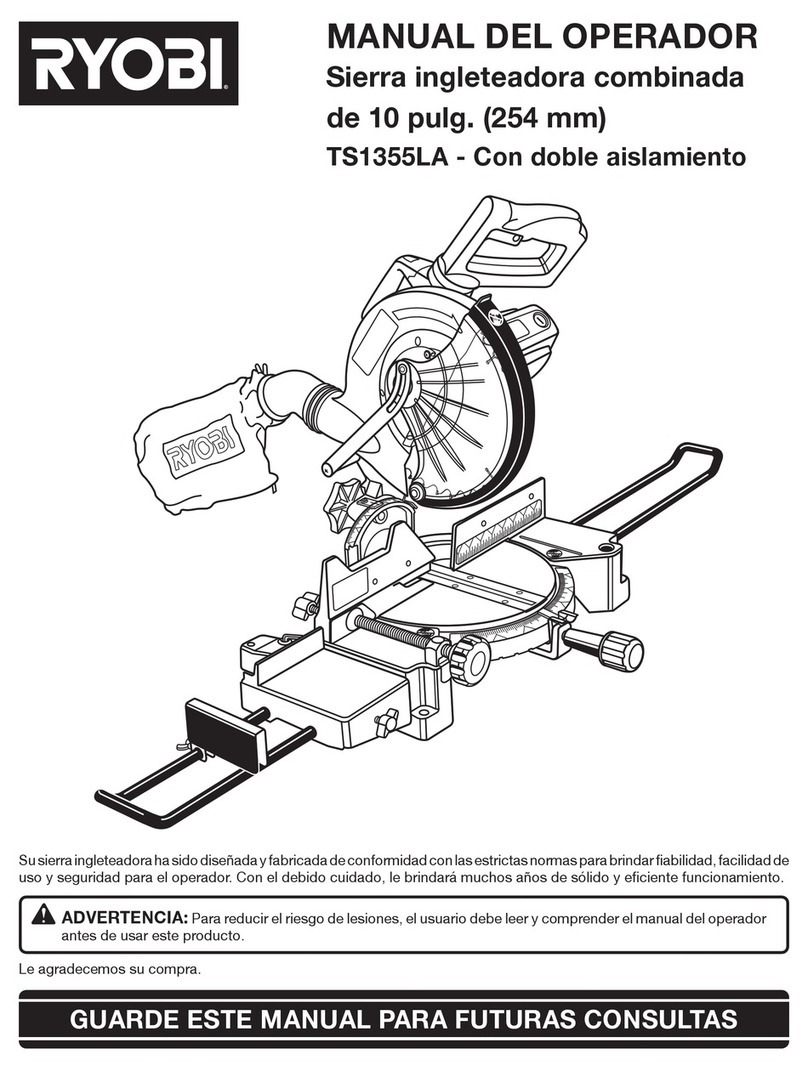

Overview

Motor housing

Angle adjustment lever

Lower blade guard

Blade bolt

Baseplate

Connection for dust extractior

Housing blade

1

2

3

4

5

6

7

Parallel fence

Saw blade wrench

Laser

Laser on / off switch

Head handle

Pull switch

The second handle

8

9

10

11

12

13

14

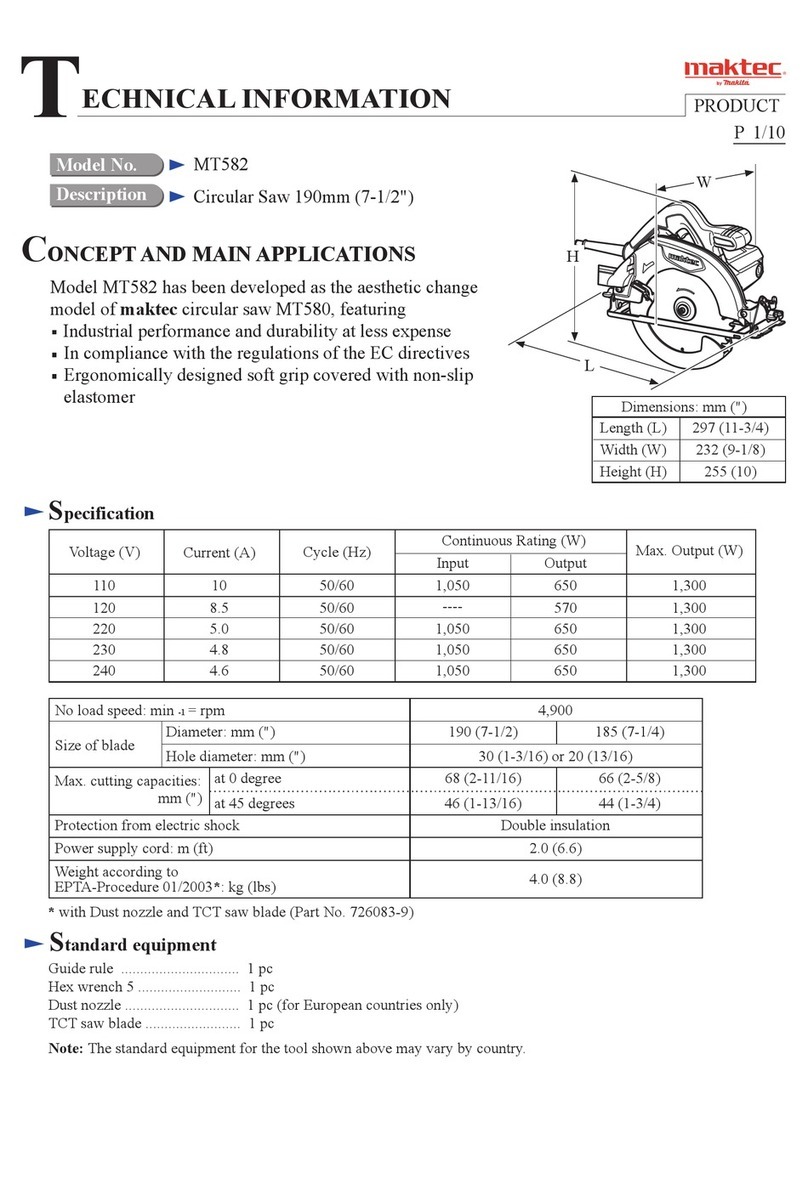

General Specification

Voltage: 120V/60Hz

Power: 13A

No load speed: 5500 /min

Blade diameter: 7-1/4”

Depth of cut at 90°: (2-1/2”) Depth of cut at 45°:(1-3/4”)

The sound intensity level for the operator may exceed 85dB(A) and sound protection

measures are necessary.

Set includes these parts:

1 Circular Saw

1 7-1/4in. tungsten carbide tipped blade(tted)

1 Parallel Fence

Pack contents / General Specication

1 Saw Blade Wrench

1 Instruction manual

1 Warranty card

WARNING

4

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw Operation& Electrical Safety

Always ensure that the saw is switched off and unpluged from

the power supply before making any adjustment.

WARNING

The direction in which the blade rotates has to be the same

as the direction of the arrow marked on the housing. Ensure

that spindle lock button is released.

Before using the saw again, check that the safety devices are in good

working order.

IMPORTANT. After replacing the saw blade, make sure that the saw

blade runs freely by tuming the blade by hand. Plug the machine into a

power socket and run the saw under no load to check that it runs

smoothly before using it to cut any material.

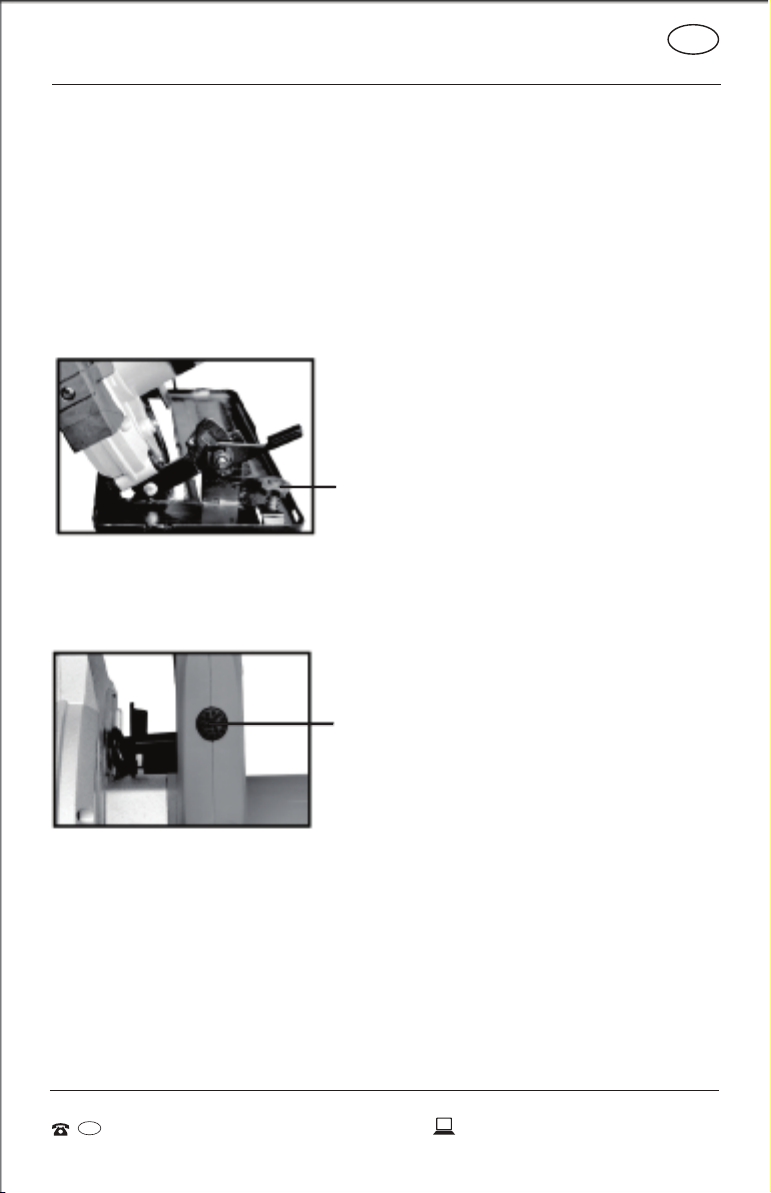

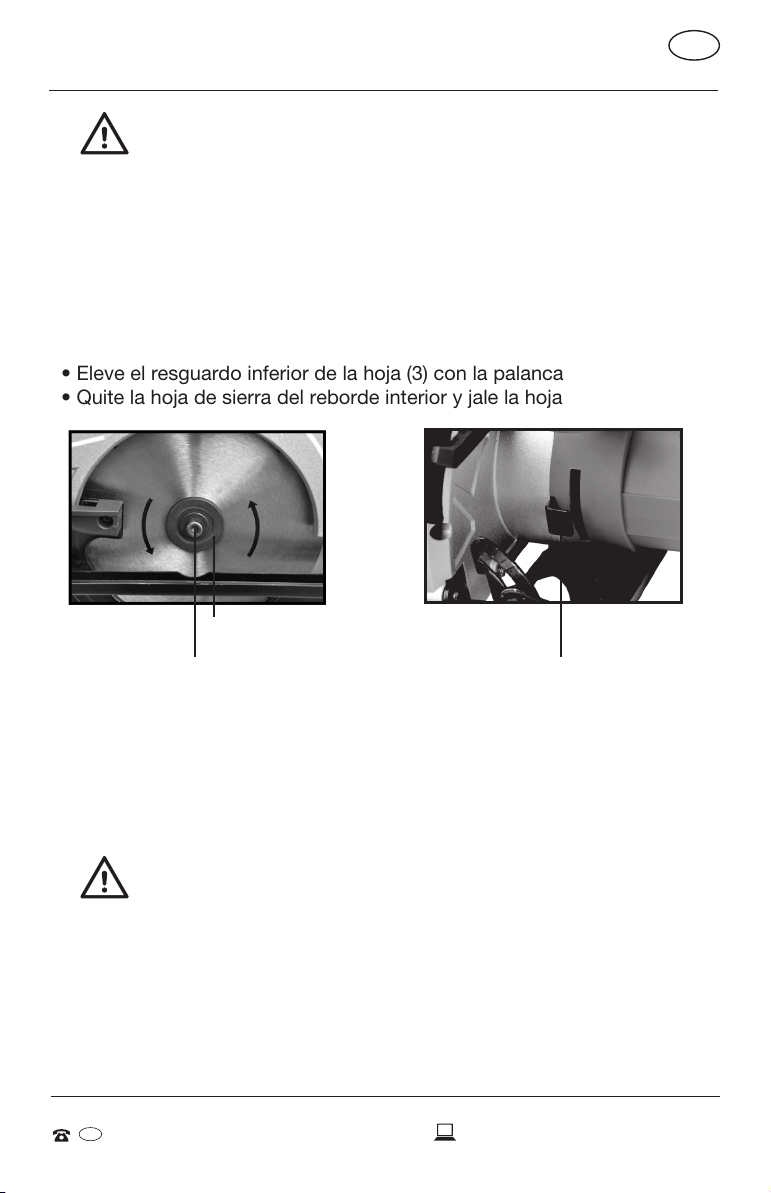

CHANGING THE BLADE CAUTION

• Place saw on its side on a at surface

• Rotate the saw blade by hand whilst depressing spindle lock button until

the blade locks

• Whilst depressing spindle lock button,turn the blade bolt anti-clockwise

using wrench

• Remove the outer blade ange and the blade bolt

• Raise the lower blade guard(3) using lever

• Remove the saw blade from the inner ange and pull out the blade

NOTE

Clean the saw blade ange thoroughly before mounting the new saw

blade. Wipe a drop of oil onto the inner and outer ange where they will

touch the blade.

Mount the new saw blade onto the spindle and against the inner ange

Replace the outer ange and tighten the blade bolt.

Spindle buttonBlade bolt

Flange

Operation& Electrical Safety

5

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

WARNING

Check carefully that there are no cracks or other damage to

the saw blade.

Replace any cracked blades immediately.

CHANGING THE BLADE CAUTION

• Place saw on its side on a at surface

• Rotate the saw blade by hand whilst depressing spindle lock button until

the blade locks

• Whilst depressing spindle lock button,turn the blade bolt anti-clockwise

using wrench

• Remove the outer blade ange and the blade bolt

• Raise the lower blade guard(3) using lever

• Remove the saw blade from the inner ange and pull out the blade

CAUTION. Always ensure that the saw is switched off and unplugged

from the power supply before making any adjustments.

• Loosen lever

• Lift the body of the saw until the blade is at the right depth - as shown

on depth adjustment scale

• Tighten lever

NOTE

Always use the correct blade depth setting. The correct blade depth

setting for all cuts should not be more than 6.35mm (1/4”) below the

material being cut. Allowing more depth will increase the chance

of kickback and result in a rough cut.

ADJUSTING THE BEVEL ANGLE

Loosen knob and tilt the body of the saw until the required angle is

reached using scale as a guide.

Tighten knob NOTE. Always make a trial cut in a scrap piece of material

along a guideline to check the position of the blade relative to the guide-

line and the angle of cut.

Depth adjust

Angle lock knob

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Operation& Electrical Safety

6

• Loosen lever

• Lift the body of the saw until the blade is at the right depth - as shown

on depth adjustment scale

• Tighten lever

NOTE

Ensure that the parallel fence rests against the wood along its entire length

to give a consistent parallel cut.

USING THE PARALLEL FENCE

The parallel fence (8) allows you to make parallel cuts in a sheet of wood, all

at the same width.

Loosen wing screw. Slide the parallel fence (8) through the slots in the base

plate (5). Adjust the parallel fence to the required width and secure it in

position with wing screw.

Do not stare directly at the laser beam.

Never aim the beam at any person or an object other than the workpiece.

Do not deliberately aim the beam at personnel and ensure that it is not

directed towards the eye of a person for longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy workpiece without

reective surfaces. I.e. wood or rough coated surfaces ard acceptable.

Bright shiny reective sheet steel or the like is not suitable for laser use as

the reective surface could direct the beam back at the operator.

Only turn laser beam on when tool is on workpicec.

USING THE LASER GUIDE

Press the laser on button according to your requirements,or you can switch

off the button when it is not neccessary.

Wing screw

Laser on/off button

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

7

NOTE

After completing your cut, release the switch (13) and allow the blade to

come to a complete stop.

Do not remove the saw from the workpiece while the blade is moving.

NOTE

When making a cut always use steady,even presure. Forcing the saw

causes rough cuts and could shorten the life of the saw or cause

kickback.Allow the blade and the saw to do the work.

MAKING A CUT

Mark the line of cutting on the workpiece and align with the corret notch

Rest the front edge of the base on the workpiece Start the motor and let the

blade reach full speed (approximately 2 seconds.Slowly push the saw

forward using both hands)

KICKBACK

• Kickback is a sudden reaction to a pinched, bound or misaligned saw

blade, causing the saw to lift up out of the work area towards the

operator.

• When the blade is pinched or bound tightly by the kerf (a kerf is a cut

which has been made by the saw) closing down, the blade stalls and the

motors reaction drives the unit rapidly back towards the operator

causing kickback.

• If the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig nto the top surface of the wood causing

the blade to climb out of the kerf and jump back towards the operator

causing kickback.

Kickback is the result of saw misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper precautions as given

below.

• Mark the line of the cut on the workpiece.

• Adjust the depth of cut and bevel angle as required.

• Rest the front edge of the base plate (5) on the workpiece.

• Switch on the laser beam using button (11).

• Align the beam with the line on the workpiece.

• Start the motor, let the blade reach full speed and slowly push the saw

forward using both hands, keeping the red laser light beam on the line of cut.

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

8

WARNING

Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, re

and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

a. Arms to resist kickback forces. Position your body to either side of the

blade, but not in line with the blade.

Kickback could cause the saw to jump backwards, but kickback forces

can be controlled by the operator, if proper precautions are taken.

b. When blade is binding, or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade

comes to a complete stop. Never attempt to remove the saw from the

work or pull the saw backward while the blade is in motion or kickback

may occur.

Investigate and take corrective actions to eliminate the cause of blade

binding.

c. When restarting a saw in the workpiece, centre the saw blade in the kerf

and check that saw teeth are not engaged into the material. If saw blade

is binding, it may walk up or kickback from the workpiece as the saw is

restarted.

d. Support large panels to minimize the risk of blade pinching and kickback.

Large panels tend to sag under their own weight. Supports must be

placed under the panel on both sides, near the line of cut and near the

edge of the panel.

e. Do not use dull or damaged blades. Unsharpened or improperly set

blades produce narrow kerf causing excessive friction, blade binding and

kickback.

f. Blade depth and bevel adjusting locking levers must be tight and secure

before making cut. If blade adjustment shifts while cutting, it may cause

binding and kickback.

g. Use extra caution when making a “plunge cut” into existing walls or other

blind areas. The protruding blade may cut objects that can cause

kickback.

General Power Tool Safety Warnings

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

9

b) Do not operate power tools in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplug

ging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk

of electric shock.

NOTE The term “residual current device (RCD)” may be replaced by the

term “ground fault circuit interrupter (GFCI)” or “earth leakage circuit

breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inatten

tion while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protec

tive equipment such as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position

10

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

before connecting to power source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your nger on the switch or energizing power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collec

tion facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power

tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

11

5) Service

a) Have your power tool serviced by a qualied repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Safety instructions for circular saws

a) DANGER: Keep hands away from cutting area and the blade. Keep your

second hand on auxiliary handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

b) Do not reach underneath the workpiece. The guard cannot protect you

from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece. Less than a

full tooth of the blade teeth should be visible below the workpiece.

d) Never hold piece being cut in your hands or across your leg. Secure the

workpiece to a stable platform. It is important to support the work

properly to minimize body exposure, blade binding, or loss of control.

e) Hold power tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own

cord. Contact with a "live" wire will also make exposed metal parts of the

power tool "live" and shock the operator.

f) When ripping always use a rip fence or straight edge guide. This improves

the accuracy of cut and reduces the chance of blade binding.

g) Always use blades with correct size and shape (diamond versus round) of

arbour holes. Blades that do not match the mounting hardware of the

saw will run eccentrically, causing loss of control.

h) Never use damaged or incorrect blade washers or bolt. The blade wash

ers and bolt were specially designed for your saw, for optimum perfor

mance and safety of operation.

Further safety instructions for circular saws

• kickback is a sudden reaction to a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to lift up and out of the workpiece

toward the operator;

• when the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit rapidly back toward the

operator.

• if the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood causing

the blade to climb out of the kerf and jump back toward the operator.

12

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

Kickback is the result of saw misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper precautions as given

below.

a) Maintain a rm grip with both hands on the saw and position your arms to

resist kickback forces. Position your body to either side of the blade, but

not in line with the blade. Kickback could cause the saw to jump back

wards, but kickback forces can be controlled by the operator, if proper

precautions are taken.

b) When blade is binding, or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade

comes to a complete stop. Never attempt to remove the saw from the

work or pull the saw backward while the blade is in motion or kickback

may occur. Investigate and take corrective actions to eliminate the cause

of blade binding.

c) When restarting a saw in the workpiece, centre the saw blade in the kerf

and check that saw teeth are not engaged into the material. If saw blade

is binding, it may walk up or kickback from the workpiece as the saw is

restarted.

d) Support large panels to minimise the risk of blade pinching and

kickback. Large panels tend to sag under their own weight. Supports

must be placed under the panel on both sides, near the line of cut and

near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or improperly set

blades produce narrow kerf causing excessive friction, blade binding and

kickback.

f) Blade depth and bevel adjusting locking levers must be tight and secure

before making cut. If blade adjustment shifts while cutting, it may cause

binding and kickback.

g) Use extra caution when making a "plunge cut" into existing walls or other

blind areas. The protruding blade may cut objects that can cause kickback.

Safety instructions for circular saws with inner pendulum guard

a) Check lower guard for proper closing before each use. Do not operate the

saw if lower guard does not move freely and close instantly. Never clamp or tie

the lower guard into the open position. If saw is accidentally dropped, lower

guard may be bent. Raise the lower guard with the retracting handle and

make sure it moves freely and does not touch the blade or any other part, in

all angles and depths of cut.

b) Check the operation of the lower guard spring. If the guard and the spring

are not operating properly, they must be serviced before use. Lower guard

AFTER SALES SUPPORT

USA

USA

13Amp 7-1/4in. Circular Saw

Power Tool Use & Care

13

may operate sluggishly due to damaged parts, gummy deposits, or a

build-up of debris.

c) Lower guard may be retracted manually only for special cuts such as "plunge

cuts" and "compound cuts." Raise lower guard by retracting handle and as

soon as blade enters the material, the lower guard must be released. For all

other sawing, the lower guard should operate automatically.

d) Always observe that the lower guard is covering the blade before placing

saw down on bench or oor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its path. Be aware of the time

it takes for the blade to stop after switch is released.

Additional safety instructions

1) Do not use any abrasive wheels.

2) Wear a dust mask, if the work causes dust.

3) Use saw blades recommended by manufacture.

4) Wear ear protectors when using the tool for extended periods.

5) Be sure to inspect material. Avoid cutting other different material.

6) Be careful not to drop the tool.

7) Never swing the tool.

8) Never cover the ventilation slots, and keep them free from dust or other material.

9) Do not clamp the tool in a vise. Never cut with the tool held upside down in a

vise. This is extremely dangerous and can lead to serious accidents.

10) Never wear knitted gloves.

11) Be sure no one is below when using the tool in high locations.

12) Do not touch the blade immediately after operation. It may be hot and could

burn your skin.

13) Do not touch material after it has been cut. Cut material may be very hot.

14) Do not use cutting oil. This use of cutting oil may cause a re.

15) Do not cut workpieces covered or stained with gas, oil, solvents, thinners, etc.

Exposure to these materials may damage the transparent guard.

16) Do not remove the transparent and lower guards. If the transparent and

lower guards is damaged or missing, return tool to authorized service center

for replacement.

17) Do not start the blade when in contact with workpiece. Wait for blade to

reach full speed before beginning cut.

SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the tool “live” and shock the

operator.

USA

13Amp 7-1/4in. Circular Saw

14

AFTER SALES SUPPORT

Symbols & Warning

WARNING

Always ensure that the tool is switched off and the plug is

removed from the power point before making any adjustments

or maintenance procedures.

Always we ar sturdy gloves when handling or changing blades as they can

be very sharp.

Keep the tool’s air vents unclogged and clean at all times.

Regularly check to see if any dust or foreign matter has entered the grills

near the motor and around the trigger switch. Use a soft brush to remove

any accumulated dust. Wear safety glasses to protect your eyes whilst

cleaning.

Re-lubricate all moving parts at regular intervals.

If the body of the saw needs cleaning, wipe it with a soft damp cloth.

A mild detergent can be used but nothing like alcohol, petrol or other

leaning agent.

Never use caustic agents to clean plastic parts.

The label on your tool may include the following symbols:

LASER RADIATION DO NOT

STARE INTO BEAM

CLASS 2 LASER PRODUCT

Waste electrical products should not be disposed of with household

waste. Please recycle where facilities exist. Check with your local

authority or retailer for recycling advice.

LASER RADIATION

DO NOT STARE INTO BEAM

Maximum output < 1 mW, Wavelength: 650 nm/<1mW

CLASS II LASER PRODUCT

CAUTION/ATTENTION

To reduce the risk of injury, user must read and understand

instruction manual.

USA

13Amp 7-1/4in. Circular Saw Warranty

FULL TWO YEAR HOME USE WARRANTY

WORKZONE warrants this product for two year against defects in materials

and assembly.

This LIMITED WARRANTY does not cover products that are improperly

used, abused, altered or repaired by unauthorized personnel.

This warranty does not apply to accessories.

This warranty gives you specic legal rights and you may have other legal

rights which vary from state to state or province to province.

For warranty questions, replacement, or repair, call American Customer

Service at 1-800-505-8311.

This product is not intended for commercial use.

AFTER SALES SUPPORT

USA 1800 505 8311[email protected]

15

NOTE

This equipment has been tested to be ETL Approved.

Conforms to UL STD No.60745-1

and 60745-2-2 Certied to CAN/CSA STD C22.2

No.60745-1 and 60745-2-2

3114052

DB5711B

WARNING

Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals know to the

state of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemical are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemical: work in a

well ventilated area, and work with approved safety equipment, such as

those dust masks that are specially designed to lter out microscopic

particles.

USA

13Amp 7-1/4in. Circular Saw Explosive View & part list

AFTER SALES SUPPORT

USA 1800 505 8311 [email protected]

16

USA

13Amp 7-1/4in. Circular Saw Explosive View & part list

AFTER SALES SUPPORT

USA 1800 505 8311[email protected]

17

61X6MwercsnogaxehrennI1

2 Flat washer Ф18XФ2X6

talfretuo3

4 Saw blade

(

Φ185XΦ16X24T

)

( )

talflanretni5

6Cross recessed countersunk head

screw M4X10

dnalg7

01X4Mwercs8

9

elastic washer Ф4

9

elastic

washer

Ф4

10 Flat washer Ф4

11 movable shield handle

12 movable protecting cover

13 movable shield spring

14 bearin

g

SR-1006

bea g 600 S

revoctnorf51

tfahstuptuo61

01X3yekffurdooW71

eveelselxA81

19

Big gear wheel

19

Big

gear

wheel

rehsawgnirpseednu02

21 Shaft ringФ21

8080KHgniraebrelloreldeeN22

revocxobraeg32

21X4Mwercs42

xobraeg52

61X6Mwercs62

nmulocgnitimiL72

02X6Mstlobkcenerauqsdaehtalf82

gnirpsgnikcolfleS92

etalpgnikcolfleS03

SR-0006gniraeb13

F-02X9.3TSwercs23

33 Flat washer Ф12XФ6X1

34 Six angle groove nut M6

35

lock spanner

35

l

oc

k

spanner

9gnirgninepo63

erutamrA73

Z2-806gniraeb83

R-55X9.3TSwercs93

40 Wind rin

g

40

Wind

ring

rotats14

gnirpsgarD24

gnisuoh34

redlohhsurB44

hsurbnobraC54

revochsurB64

47 Angle Bracket(assembling with

aluminium baseboard )

niplacirdnilyccitsale84 Ф6X40

9x5tevirwollohflahdaehtalF94

50

aluminum baseboard

50

aluminum

baseboard

15 depth indicator(assembling with

l i i b b d )

52 Flat head half hollow rivet 5 x17

53 flat head square neck bolts M6X20

54 aluminium angle ruler

tunkcolrelurediuG55

55

Gu de u e oc u

bonkdorediuggnirpS65

bonkkcol75

85 cross recessed countersunk head

screw M5x12

eldnahthgir95

60

Laser switch button

60

Laser

switch

button

revoceldnahyrailixuA16

hctiwS26

F-41X9.3TSwercs36

etalpenilgnisserP46

htaehselbac56

GWA61elbac66

F-61X9.3TSwercs76

eldnahtfel86

thgilresaL96

lanimretresal07

remrofsnartresaL17

)nwod(doreriwresaL27

)pu(doreriwresaL37

74 Laser transparent cover

75 O-rings Ф8 x Ф5.1

76

Laser plate

76

L

aser p

l

a

t

e

F-21X9.2TSwercs77

)nwod(xobresaL87

)pu(xobresaL97

01x4Mwercsdaehnapssecerssorc08

81

g

relurediu

81

guide

ruler

hcnerwnogaxehrennImm528

Contenido

Descripción general...................................................................... 19

Especicaciones generales .................................................. 19

Contenidos .......................................................................... 19

Funcionamiento y seguridad eléctrica......................................... 20

Cambio de la hoja ................................................................ 20

Ajuste del ángulo de corte .................................................... 21

Uso de la guía paralela ......................................................... 22

Uso de la guía láser .............................................................. 22

Uso y cuidado de la herramienta eléctrica.............................. 23-29

Realizar un corte .................................................................. 23

Contragolpe ..................................................................... 23-24

Advertencias de seguridad ...............................................24-29

Instrucciones adicionales de seguridad ........................... 29

Símbolos y advertencia ............................................................... 30

Símbolos ............................................................................ 30

Advertencias ....................................................................... 30

Garantía ........................................................................................ 31

Vista desglosada y lista de piezas ........................................... 32-33

Tarjeta de garantía ...................................................................... 36

Condiciones de la garantía ......................................................... 37

Descripción general y

contenidos / Especificación

19

SERVICIO POSVENTA

USA

USA

Sierra circular de 7 1/4 pulg. y 13 A

Descripción general

Carcasa del motor

Palanca de ajuste de ángulo

Resguardo inferior de la hoja

Perno de la hoja

Placa de base

Conexión para el extractor

de polvo

Carcasa de la hoja

1

2

3

4

5

6

7

Guía paralela

Llave de la hoja de sierra

Láser

Interruptor de encendido /

apagado del láser

Mango del cabezal

Interruptor de halar

Segundo mango

8

9

10

11

12

13

14

Especificaciones generales

Tensión: 120 V/60 Hz

Intensidad: 13 A

Velocidad sin carga: 5500 /min

Diámetro de la hoja: 7-1/4”

Profundidad de corte a 90°: (2-1/2”) Profundidad de corte a 45°: (1-3/4”)

El nivel de intensidad del sonido para el operador puede exceder los 85 dB(A) y son

necesarias medidas de protección acústica.

El conjunto incluye las siguientes piezas:

1 Sierra circular

1 Hoja de carburo de wolframio de 7-1/4 pulg. (instalada)

1 Guía paralela

Contenidos / Especicaciones generales

1 Llave de la hoja de sierra

1 Manual de instrucciones

1 Tarjeta de garantía

20

SERVICIO POSVENTA

USA

USA

Sierra circular de 7 1/4 pulg. y 13 A Funcionamiento y

seguridad eléctrica

Cersiórese siempre de que la sierra esté apagada y

desconectada de la fuente de alimentación antes de

realizar ajustes.

La dirección en la que gira la hoja debe ser igual a la direc-

ción de la echa que se encuentra en la carcasa. Cersiórese

de que el botón de cierre del eje esté liberado.

Antes de usar la sierra de nuevo, verique que los dispositivos de

seguridad funcionan correctamente.

IMPORTANTE. Después de reemplazar la hoja de sierra, asegúrese de

que esta se deslice libremente haciéndola girar con la mano. Conecte la

máquina a un tomacorriente y encienda la sierra sin carga para vericar

que se mueva con uidez antes de usarla para cortar materiales.

PRECAUCIÓN AL CAMBIAR LA HOJA

• Coloque la hoja de lado sobre una supercie plana

• Gire la hoja de sierra a mano mientras presiona el botón de cierre del eje

hasta que la hoja se trabe

• Mientras presiona el botón de cierre del eje, gire el perno de la hoja en

sentido antihorario con la llave

• Quite el reborde exterior de la hoja y el perno de la hoja

• Eleve el resguardo inferior de la hoja (3) con la palanca

• Quite la hoja de sierra del reborde interior y jale la hoja

NOTA

Limpie el reborde de la hoja de sierra en detalle antes de montar la nueva

hoja de sierra. Esparza una gota de aceite en el reborde interior y exterior

donde tocan la hoja.

Monte la nueva hoja de sierra en el eje y contra el reborde interior. Vuelva

a colocar el reborde exterior y ajuste el perno de la hoja.

Botón del ejePerno de la hoja

Hoja

ADVERTENCIA

ADVERTENCIA

Table of contents

Languages:

Other Workzone Saw manuals

Workzone

Workzone M1Y-DU10-190 User manual

Workzone

Workzone SD1600V User manual

Workzone

Workzone CDY190FLA2 User manual

Workzone

Workzone 55903 User manual

Workzone

Workzone WZTS 1701 User manual

Workzone

Workzone WZTS 1702 User manual

Workzone

Workzone Titanium CS20V User manual

Workzone

Workzone WZTS 1700 User manual

Workzone

Workzone WWPBS-18 User manual

Popular Saw manuals by other brands

Ryobi

Ryobi TS1355LA Manual del operador

Skil

Skil SHD77 operating instructions

Bosch

Bosch BSH180BN Operating/safety instructions

Ozito

Ozito CSW-7000 instruction manual

B+BTec

B+BTec Diamond3 675TS Translation of the original operating instructions

King Canada

King Canada KC-227-2 Service manual & parts list