Dental Delivery Unit Operation Manual

Content

Revision History..........................................................................................................................2

Regulatory Requirements...........................................................................................................3

Chapter 1 Introduction................................................................................................................6

1.1. Attention.......................................................................................................................6

1.2. Usage Indications ........................................................................................................6

1.3. Contraindication...........................................................................................................6

Chapter 2 Safety.........................................................................................................................7

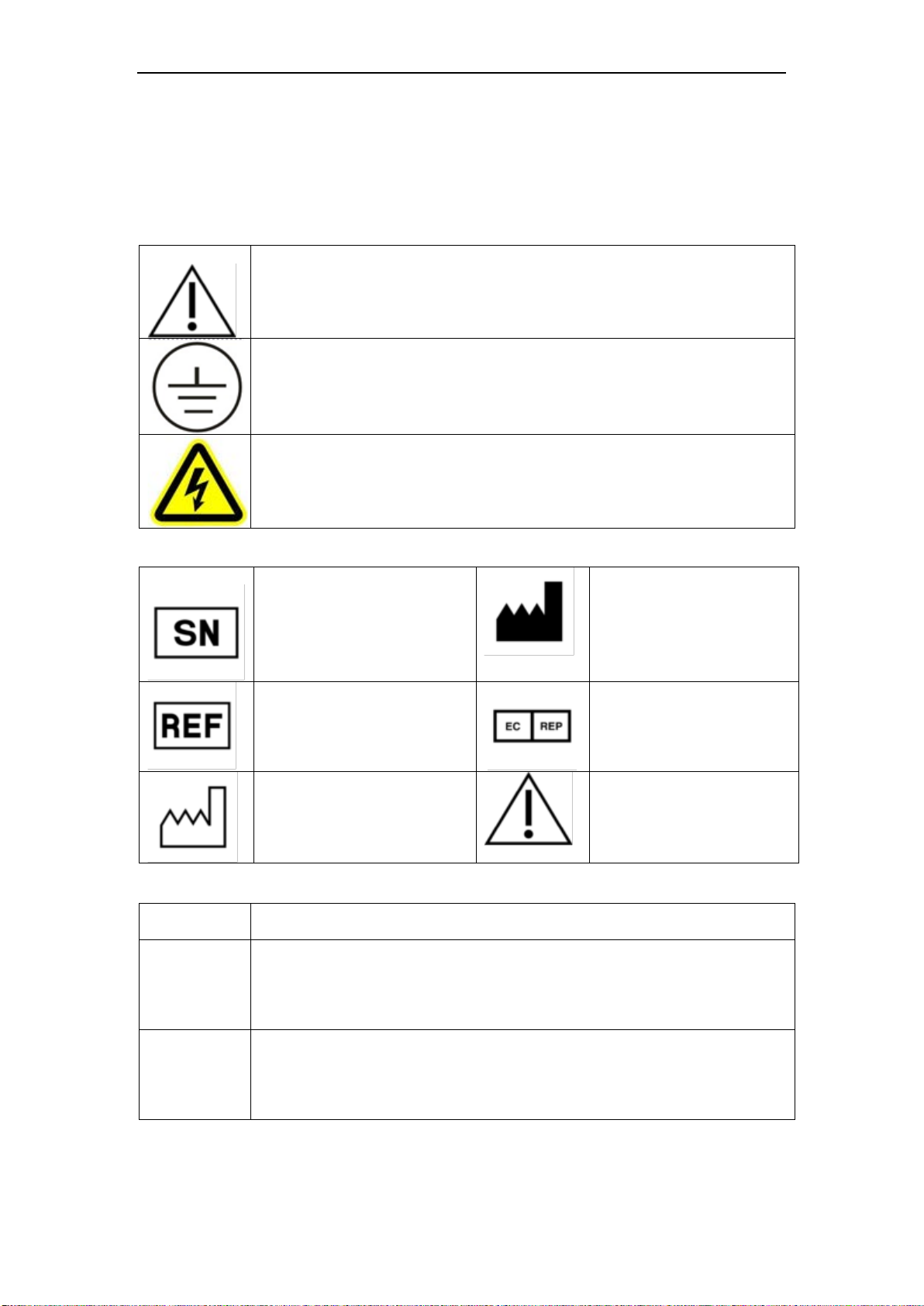

2.1. Sign Explanation..........................................................................................................7

2.2. General Safety Recommendations..............................................................................8

2.3. Safety Parts..................................................................................................................8

2.4. Operation Risk .............................................................................................................8

2.5. Protection Tool.............................................................................................................8

Chapter 3 Description and Specification ....................................................................................9

3.1 Overview.......................................................................................................................9

3.2 Specification................................................................................................................10

3.4 Appearance and Structure ..........................................................................................14

3.5 Safety Requirements...................................................................................................15

3.6 Cable and Pipeline Protection.....................................................................................15

3.7 Control Device.............................................................................................................15

3.8 Cleaning and Disinfection ...........................................................................................15

3.9 Environmental Tests....................................................................................................15

3.10 Packaging Specifications...........................................................................................15

Chapter 4 Installation................................................................................................................16

4.1 Before Installation .......................................................................................................16

4.2 Power Connection.......................................................................................................18

4.3 Fixed Dental Chair ......................................................................................................19

4.4 Exchange Position ......................................................................................................20

4.5 Pipeline Layout............................................................................................................21

4.6 Pipeline and Electron Connection...............................................................................22

4.7 Light Arm and Operation Light Assembly....................................................................22

4.8 Cuspidor Assembly .....................................................................................................22

4.9 Balance Arm Assembly...............................................................................................22

4.10 Handpiece and 3-Way Syringe Assembly.................................................................23

Chapter 5 Operation and Debugging........................................................................................24