Product

Description

Designed for use with hoisting equipment, MRTALP4-DC3 lifters support loads using vacuum and

manipulate loads using manual 180° rotation and mechanically assisted, manual 90° tilt motions.

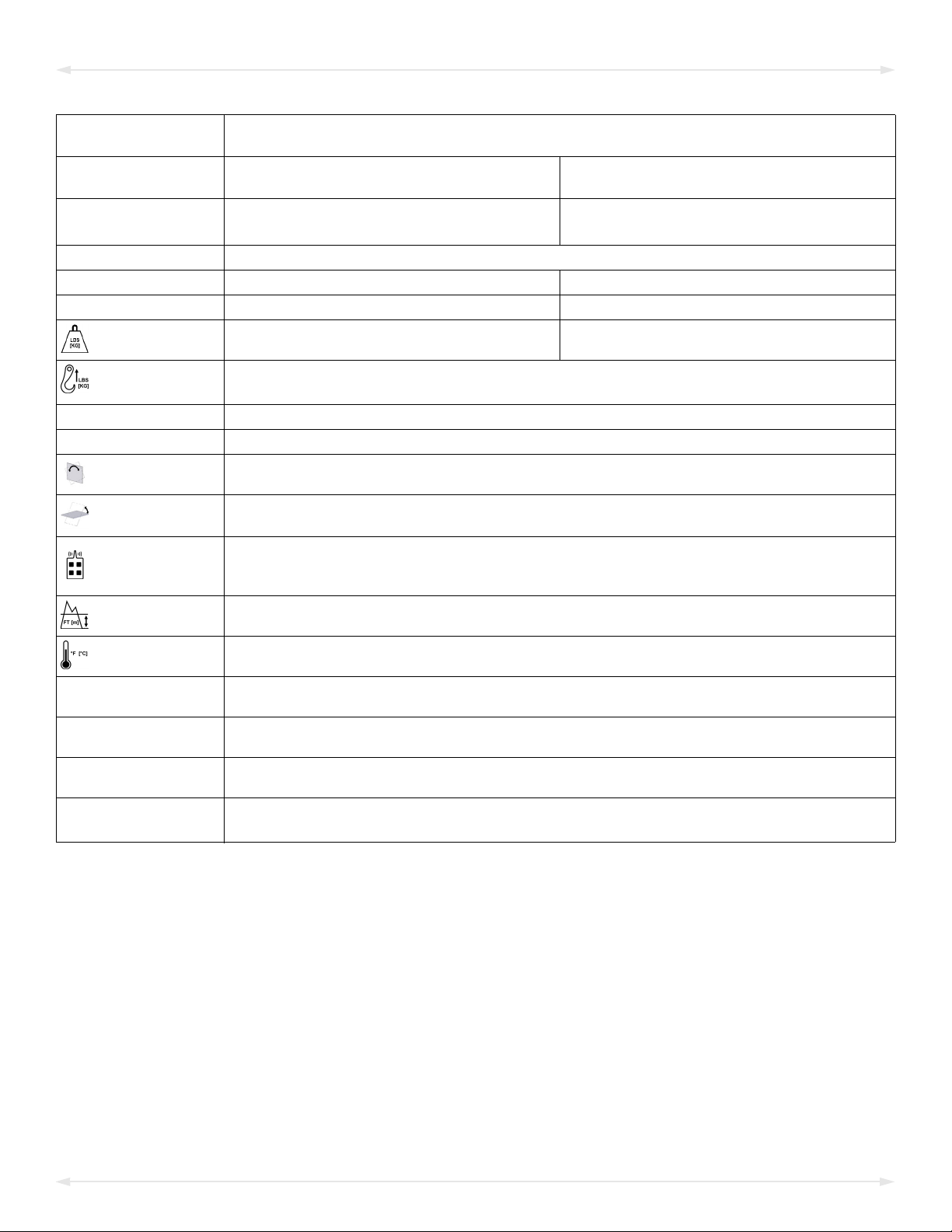

Model

Number MRTALP4625DC3 MRTALP4-DC3

with conversion to VPFS10T vacuum pads

Vacuum

Pads

Four with nominal dimensions

of 6" x 25" [15 cm x 64 cm] (Model VPFS625)1

1...... Standard with replaceable pad inserts for rough or textured surfaces (see “REPLACEMENT PARTS”).

Four 10" [25 cm] nominal diameter

(Model VPFS10T)2

2...... Standard with replaceable sealing rings for rough or textured surfaces (see “REPLACEMENT PARTS”).

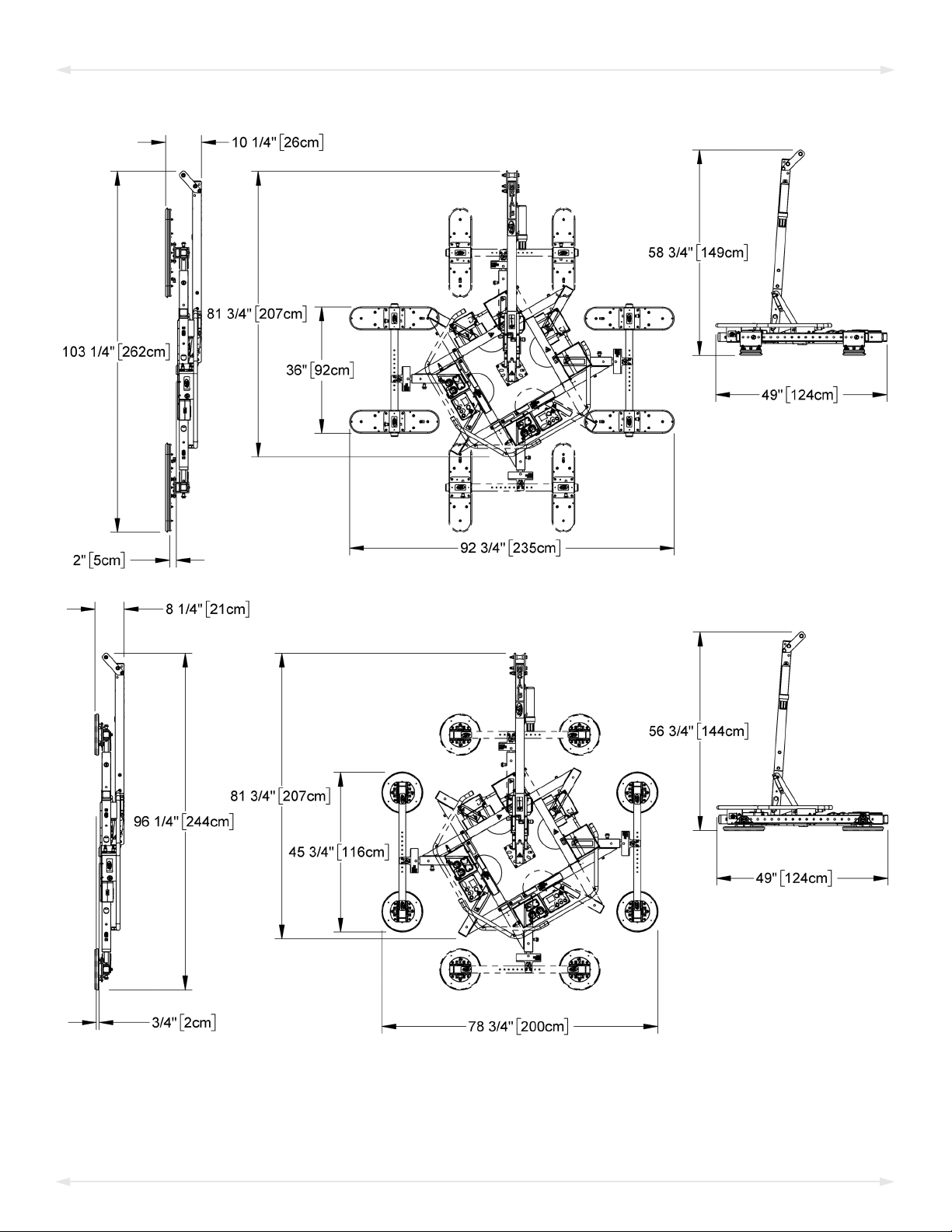

Pad Spread -------------------- (to outer edges) --------------------

Maximum 36" x 92¾" [92 cm x 235 cm] 45¾" x 78¾" [116 cm x 200 cm]

Minimum 20" x 92½" [51 cm x 235 cm] 25¾" x 78¾" [65 cm x 200 cm]

Lifter

Weight 250 lbs [114 kg] 201 lbs [92 kg]

Maximum

Load Capacity3

3...... The Maximum Load Capacity is rated at a vacuum of 16" Hg [-54 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A “qualified

person” should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test”).

Per Pad: 150 lbs [68 kg]

Total: 600 lbs [270 kg]

Power System 12 volts DC, 5.5 amps

Battery Capacity 18 amp-hours

Rotation

Capability Manual, 180°, with latching at every 30° of revolution (when required)

Tilt

Capability

Manual, 90°, with four-bar tilt linkage that provides mechanical advantage and automatic latching in

upright position

Product

Options

Available with Remote Control System – FCC, CE, ICC, RSM and ACMA compliant.

Available with conversion to VPFS10T vacuum pads

See separate instructions about other options.

Operating

Elevation Up to 6,000' [1,828 m]

Operating

Temperatures 32° – 104° F [0° – 40° C]

Service

Life 20,000 lifting cycles, when used and maintained as intended4

4...... Vacuum pads, filter elements and other wear-out items are excluded.

Software

Version Intelli-Grip®7.6

ASME Standard

BTH-1 Design Category "B", Service Class "0"

Troubleshooting

Guide5

5...... To view this guide, click the link at right. Additionally, you can search for your lifter's Model Number at www.wpg.com and select the “Troubleshooting” link

on the product page.

TST-021_DC3_REV_2018-023

Rev 7.5/6-22 MRTALP4-DC3: #350583

SPECIFICATIONS