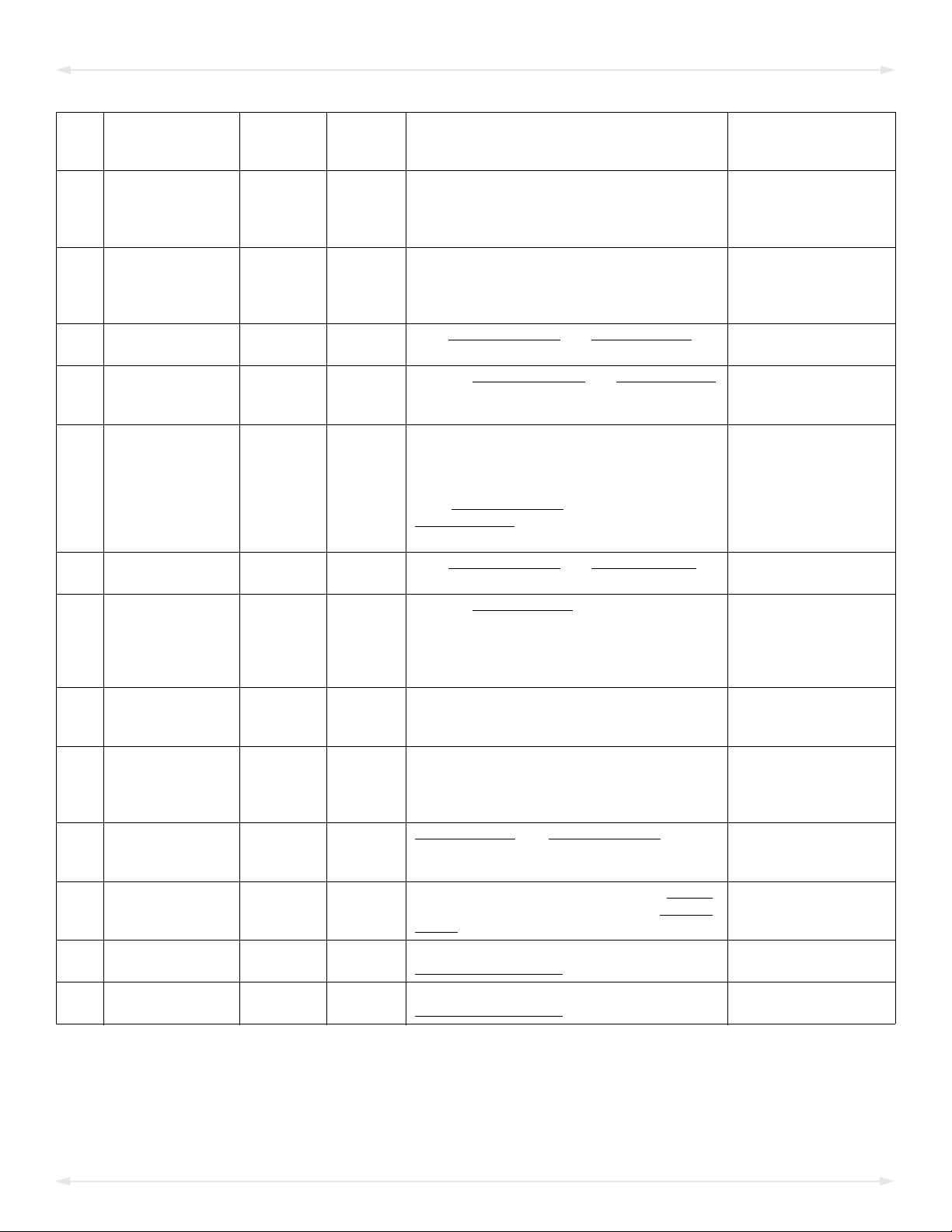

Rev 2.0/4-20 DC3 DVS, Powered Motion: #361087

M02 “Motion setting

saved” single chirp (none)

Motion setting has been saved to memory and

will be used to control the motion from this

point forward. No corrective action is necessary.

N/A

N00 “Automatic

attach” (none) (none)

System activated “attach” mode as precaution

because significant vacuum was detected, even

though no one initiated “attach” function. No

corrective action is necessary.

N/A

N01 “Automatic

attach” (none) (none)

System activated “attach” mode as precaution

because load did not release completely. No

corrective action is necessary.

N/A

N02 “Automatic

attach” (none) (none)

System activated “attach” mode as precaution

when lifter was powered up, because power

was previously lost while load was attached. No

corrective action is necessary.

N/A

N03 “Unable to turn

module power off”

1 chirp

every 2

seconds

(none)

Modular circuit board failed to power down.

Remove 9V battery. Disconnect connector

between 12V battery and vacuum generating

system. Charge battery completely (see

“MAINTENANCE: 12-VOLT BATTERY RECHARGE” in

lifter's OPERATING INSTRUCTIONS). Then

reconnect battery and try to power down again.

If code persists, disconnect connector. Service is

required.

Check for fault(s) in

cable connecting to

modular circuit board.

Disconnect 12V battery

and replace cable or

circuit board as needed.

N04

“Failed to turn

controls power

off”

1 chirp

every 2

seconds

(none)

Control unit failed to power down. Remove 9V

battery. Disconnect connector between 12V

battery and vacuum generating system. Charge

battery completely (see “MAINTENANCE: 12-

VOLT BATTERY RECHARGE” in lifter's OPERATING

INSTRUCTIONS). Then reconnect battery and try

to power down again. If code persists,

disconnect connector. Service is required.

Disconnect 12V battery

and replace control unit

as needed.

N05 “Unable to turn

module power on”

1 chirp

every 2

seconds

(none)

Modular circuit board failed to power up.

Charge 12V battery (see “MAINTENANCE: 12-

VOLT BATTERY RECHARGE” in lifter's OPERATING

INSTRUCTIONS). Then power lifter up again. If

code persists, service is required.

Disconnect 12V battery

and replace modular

circuit board.

N06 “Power-down

reminder” 2 chirps on briefly Power down to prevent 12V battery discharge

when lifter is not in use. N/A

N07 “Auto power-down

disabled” (none) (none)

Automatic power-down is prevented. Power

down lifter and power up again. If code persists,

service is required.

Check for other

Diagnostic Codes and

perform service as

directed.

N08 “Powering down in

# seconds”

1 chirp per

minute (none)

Lifter will automatically power down in number

of seconds shown. Press any button to cancel

action.

N/A

N10 “App-support

hardware fault” (none) (none)

Fault is detected in hardware that enables

communication with mobile app. Power down

lifter and power up again. If code persists,

service is required.

Disconnect 12V battery

and replace control unit

to resolve.

Code On-Screen

Message

Buzzer

Pattern

Strobe

Light

Activity

Operator Explanations/Directions Service Personnel

Directions

INTELLI-GRIP®DIAGNOSTIC CODES