FGT003

Product information

Page 4 of 4 Subject to technical changes FGT003_V4.3.0_PI_2017-12_EN

Set address

To correctly register the FGT003 on the bus, you must assign it a unique address using the rotary

switch. This is a requirement for functioning communication with the master module.

Addresses 0-F can be set with the rotary switch. As such, 16 field modules can be connected to the

bus.

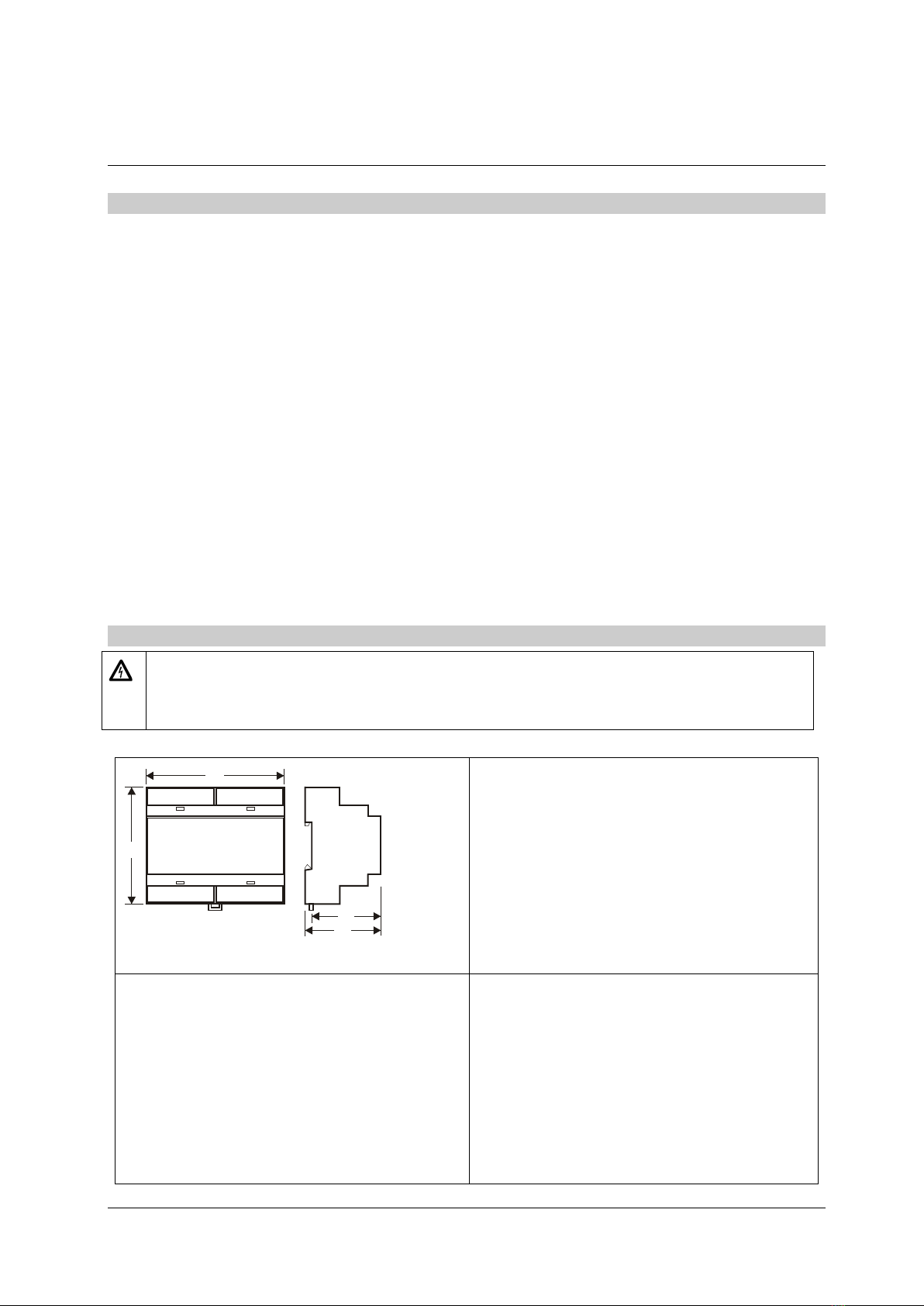

Fig. 4: FGT003 rotary switch

Technical data

Power supply 230V~, +10% / -15%, max. 10VA

Display 1 x green LED, operating voltage

2 x green LED, CAN bus data traffic (CAN Tx, CAN Rx)

1 x red LED, flashing in case of fault

Communication 3-wire CAN bus interface, shielded, galvanically isolated,

Screw terminals or RJ45 socket (2x)

Temperature sensor 4 x TRK277 / DGF980

Analogue input 4…20 mA or 0…10 V=, 22 V= supply voltage

Max. 3VA (supply via terminal 47)

Digital inputs 24V=, +20% / -10%, approx. 5mA per input

Output relay 2 x normally closed contact, 230V~, 4(2)A

1 x normally open contact 230V~, 4(2)A

Display / circuit breaker

connection 1 x socket for prefabricated line to display DSP002, DSP100, DSP-

LCD, DSP-Booster or for controlling an ECA970 circuit breaker

Analogue output 1 x 0...10V=, tied to potential, capable of bearing max. 10mA

PWM output 1 x 0...10V=, tied to potential, capable of bearing max. 10mA

Dimensions (WxHxD) 106 x 92 x 58mm (DIN 43880)

Fastening Top-hat rail TH 35-15 or TH 35-7.5 (DIN EN 60715)

Ambient temperature Operation: 0...+55°C, storage: -25...+70°C

Weight About 275g

CE conformity

−2014/30/EU (EMC Directive)

−2014/35/EU (Low Voltage Directive)

RoHS II

Valid from Version 4.3.0