MDC901-EVBHB Rev2021Jan5 MinDCet NV www.mindcet.com

Attention: Please refer to Evaluation Kit Important Notice on page 20 Page 10

3. Install the plastic spacer studs in each corner of the

EVB

a. 4 cm studs on the PCB bottom side

b. 2 cm studs on the top side

4. Connect the power cables:

a. Ring terminals to the PCB using the included

bolt + washer + nut (according to Figure 5)

b. Free end to the power supply/load (with

appropriate connector on bare-end as

necessary). Vbus to high voltage power

supply, Vout to (electronic) load

5. Connect the Vin supply cable

a. Ferule to the PCB terminal block Vin

b. Banana connector to the power supply

6. Connect the coaxial cable

a. BNC connector to AWG

b. Female header to VinHS for BUCK mode

7. Install the plexiglass cover on the spacer studs

Powering Up: General-Sequence

1. Check if the desired setpoint is within the limits of temperature, current and voltage (see Dead time

Control Condition)

2. Ensure all preparations (previous section) were properly completed. (see previous section)

3. Verify the LED status

a. PG 5V: ON

b. PG 12V: ON

c. PG Vbus: OFF

4. Setup the desired jumper combinations (refer to Dead Time Control Conditions)

a. Dead-time: automatic or manual

b. Switching mode: buck/boost - synchronous/ asynchronous

c. Enable pin to 5V

5. Set the PWM signal to the desired frequency and duty cycle. (if not regulated in closed loop)

6. Increase Vbus while monitoring Vout. (only continue when the output is as expected)

7. Increase the output load current while monitoring Vout.

8. Lower Vbus and Iout back to zero when finished

Measurement Example: Buck Mode with Auto Dead-Time

1. Follow this guidance as an add-on for the previous section “powering-up: general-sequence”

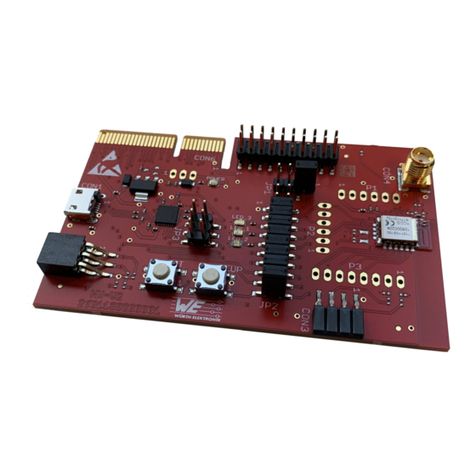

2. Setup jumpers like in the image:

a. Auto dead time: DT-select=GND (pull down makes this unnecessary)

b. Buck mode: MLS_SEL=5V (MHS_SEL=GND - pull down makes this unnecessary)

3. Set the PWM frequency to 300kHz and duty cycle to 25%

4. Increase the voltage of Vbus to 48V

5. Verify whether the output voltage is 12V

6. Increase the load current up to 5A and measure Vbus, Ibus, Vout and Iout

7. Power down Vbus to 0V and the load current Iout to 0A