Doc 1 – Issue 2 Page 2 of 16

CONTENTS

CONTENTS...........................................................................................................................2

GENERAL INFORMATION AND SAFETY SUMMARY ...................................................3

Safety Precautions ..............................................................................................................3

Introduction........................................................................................................................3

Functional and Equipment Description of System...............................................................3

CHAPTER 1 ..........................................................................................................................4

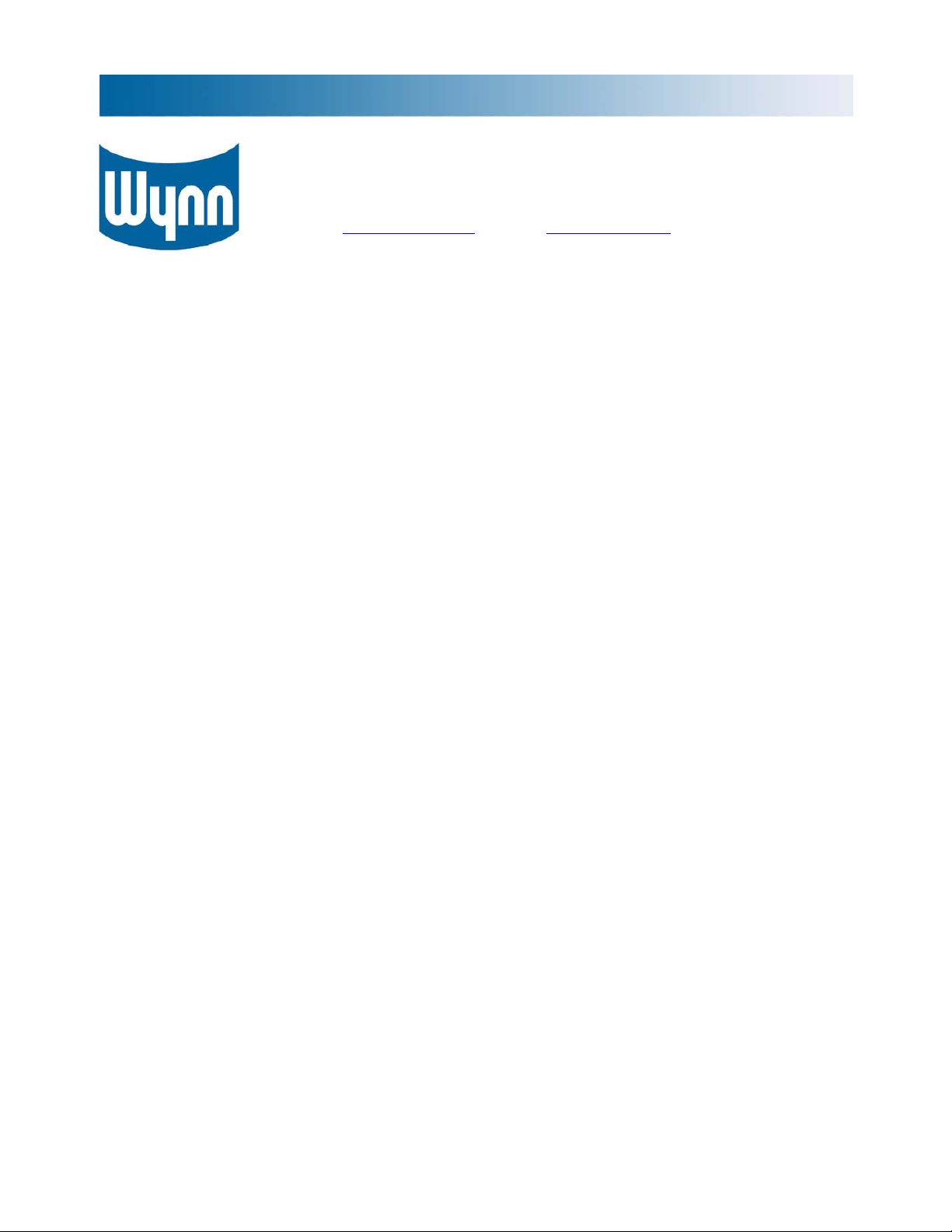

Wiper Motor Assembly...................................................................................................4

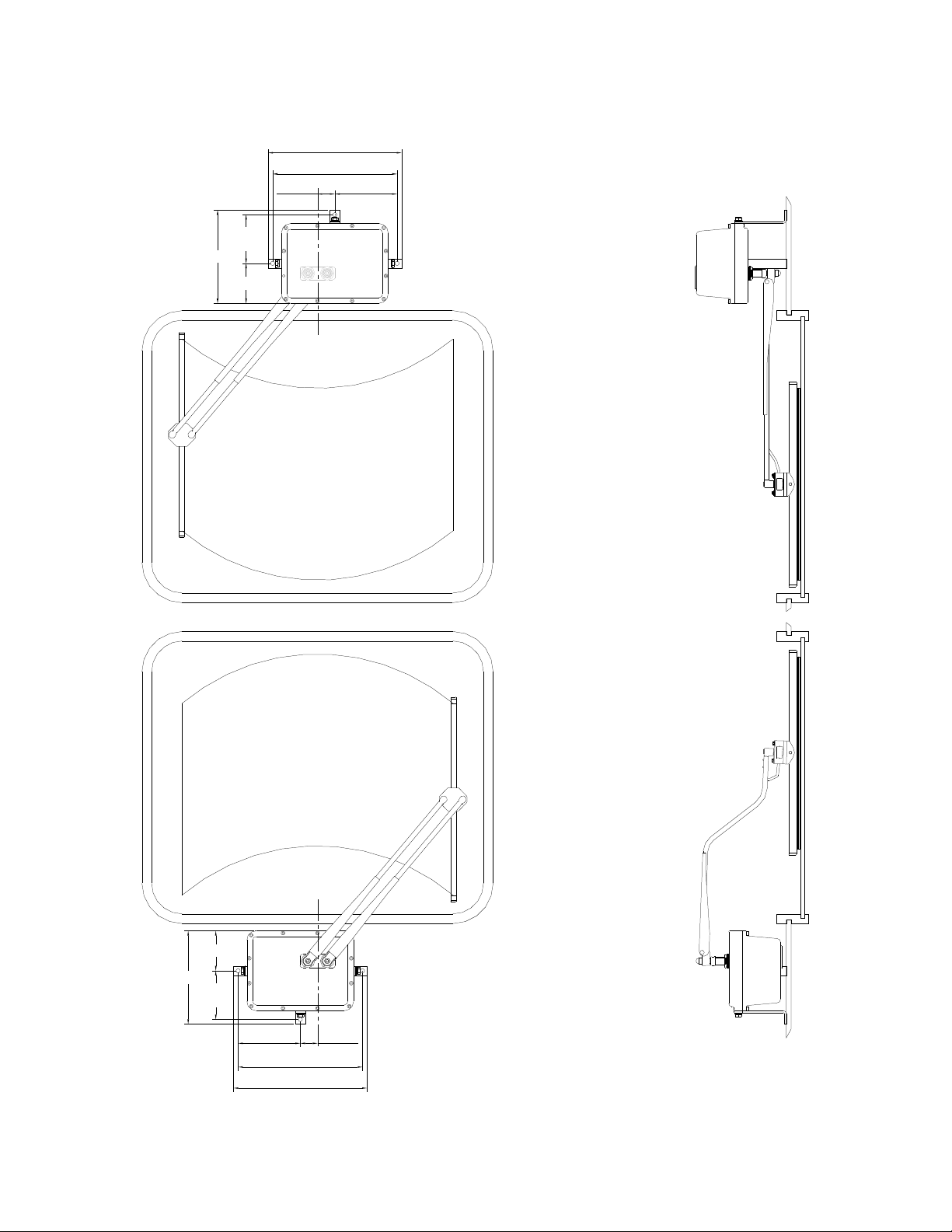

1850 0 – range arms ...............................................................................................................6

Cranked Arms – Outboard Facing Spindles ........................................................................6

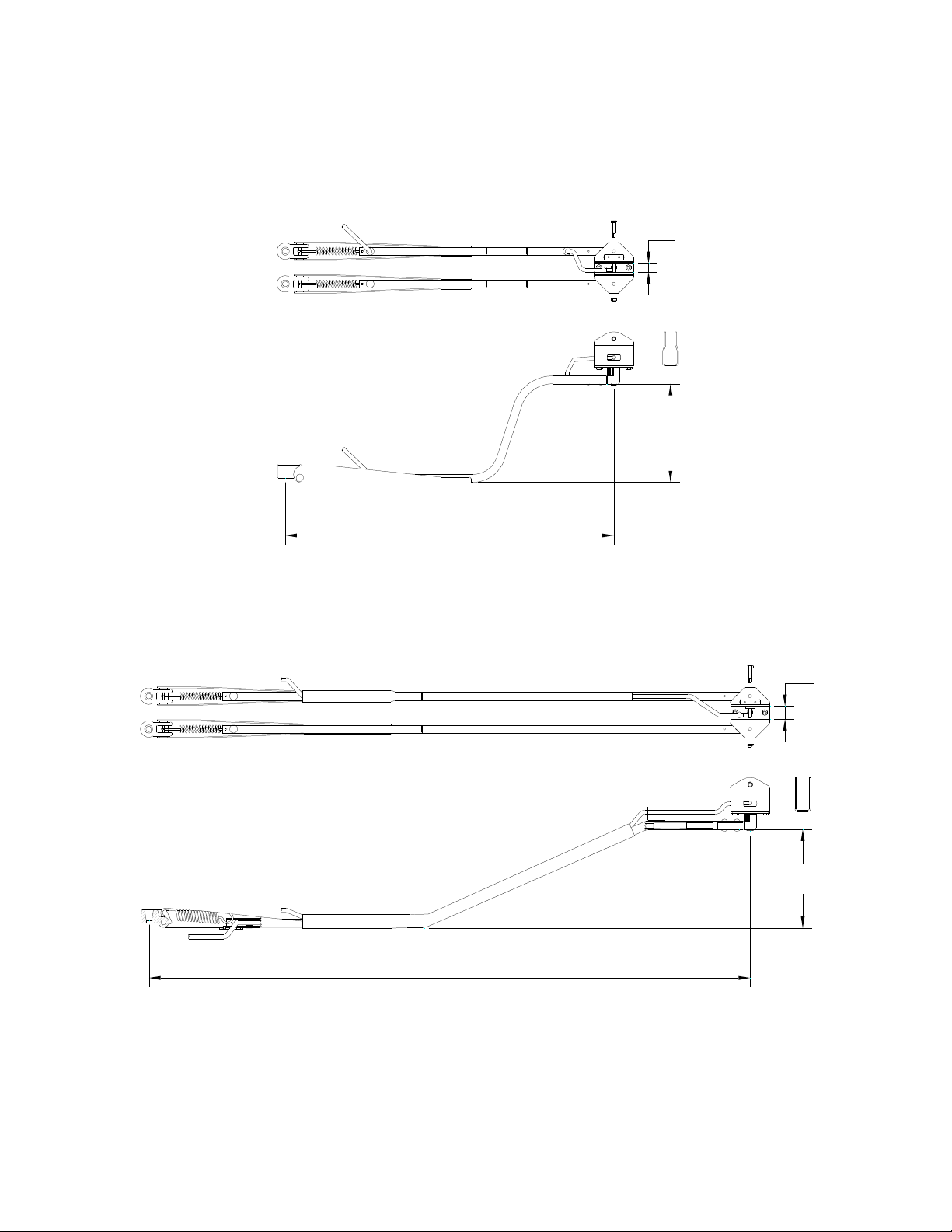

1850 1 – range arms ...............................................................................................................7

Straight Arms – Inboard Facing Spindles............................................................................7

CHAPTER 2 ..........................................................................................................................8

Installation Instructions.......................................................................................................8

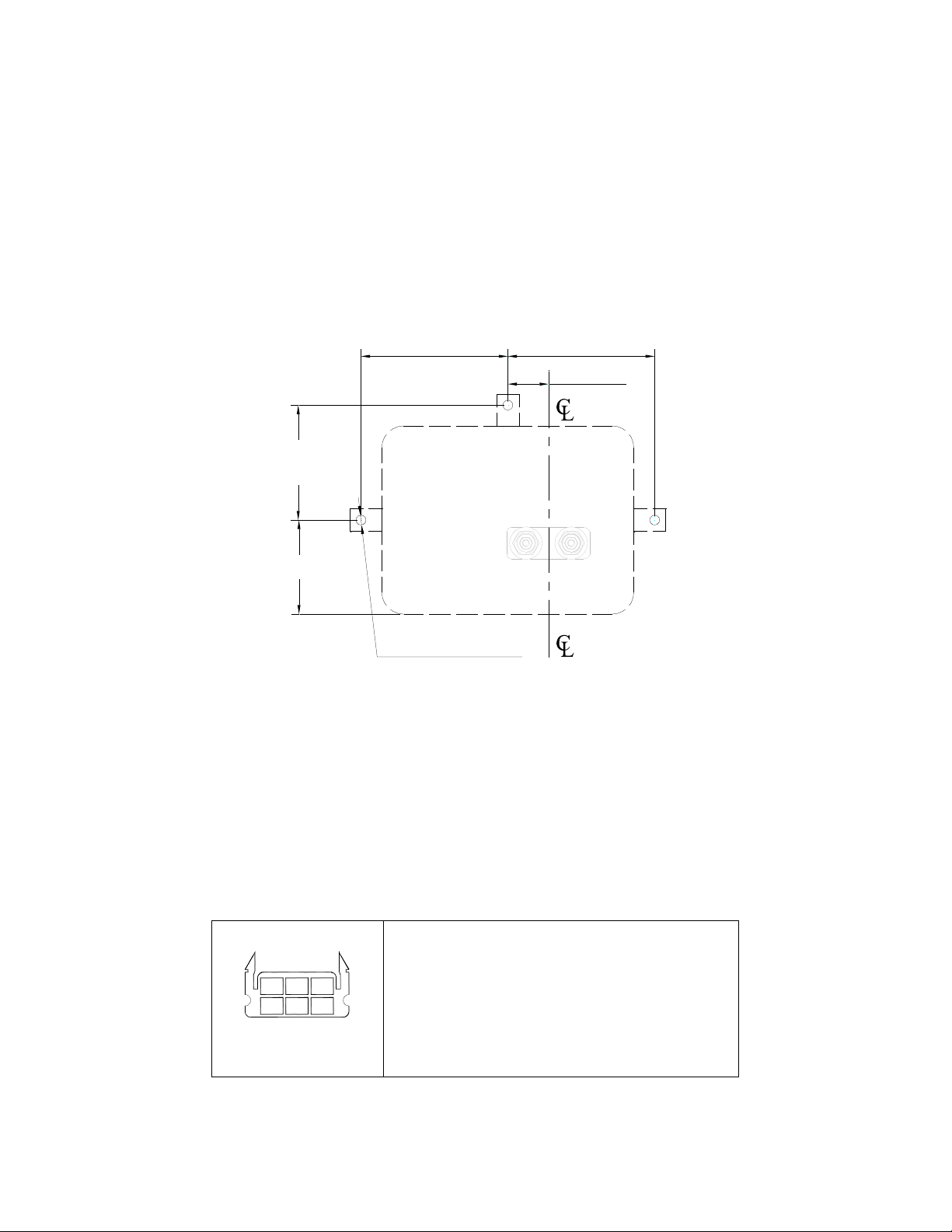

Drilling Diagram ............................................................................................................8

Fitting the Wiper Motor Assembly..................................................................................8

Fitting the Wiper Blade...................................................................................................9

Fitting the Wiper Arm Assembly ....................................................................................9

CHAPTER 3 ........................................................................................................................10

Maintenance .....................................................................................................................10

Introduction ..................................................................................................................10

Safety Precautions ........................................................................................................10

Scheduled Maintenance Action Check ..........................................................................10

Table 1 .........................................................................................................................10

CHAPTER 4 ........................................................................................................................11

Troubleshooting................................................................................................................11

Introduction ..................................................................................................................11

Safety Precautions ........................................................................................................11

Troubleshooting Procedures..........................................................................................11

Table 2 .........................................................................................................................11

Table 2 - Continued ......................................................................................................12

CHAPTER 5 ........................................................................................................................13

The Extractor....................................................................................................................13

Switch Operation – Multi-Switch......................................................................................13

SPARES LIST......................................................................................................................14