Page 10 Model 590-10

© 2002 Xantech Corporation

EDITING AND TESTING IR COMMANDS

If a brand, component or function is not found in Palette Editor, each can be added as follows:

Adding Brands

1. If the brand you need is not already on the list, choose the Component menu and click on “ADD BRAND”.

2. Type brand name and press enter on the keyboard or click OK.

3. The new name is added and saved to the list.

Adding Components and Functions

1. If the component you need is not already on the list, choose the Component menu and click on “ADD

REGULAR COMPONENT”.

2. Type component name and press enter on the keyboard.

3. Type the name of a function for this new component in the text box and press enter on the keyboard to save

new function.

4. Repeat step 3 for all functions required for the new component.

5. Press “Esc” on keyboard to save and exit.

6. New Brands, Components and Functions can now be selected and programmed in Palette Editor.

Other Editing Functions

• Help. Gives basic help information for the Palette Editor.

• Close. Closes the Palette Editor when you have finished editing. Auto-save feature saves all IR commands

and created palettes.

• To access the Delete, Rename and New Function attributes, right click within the list of commands. A pop-

up menu showing each of the above appears.

• For Delete and Rename, right click the desired command first, then left click either Delete or Rename and

follow the prompts.

• For New Function, right click within the list, then left click New Function. Follow the prompt. When finished,

click the Close button. Any changes will be saved automatically.

GETTING SOURCE COMMANDS FROM THE INTERNET

Xantech.com

There are some IR commands that can be difficult to learn in Dragon. Xantech edits and posts some of these

commands at xantech.com under Products/IR Code Libraries. (See website for listings and download

instructions.) A direct link to xantech.com can be found in the “Links” option in the Dragon menu bar.

Remote Central.com

There is a second option for on line IR codes. remotecentral.com provides an almost unlimited resource of IR

commands. The code files at Remote Central are not directly compatible with Dragon Drop-IR and therefore need

to be converted for use with Xantech software.

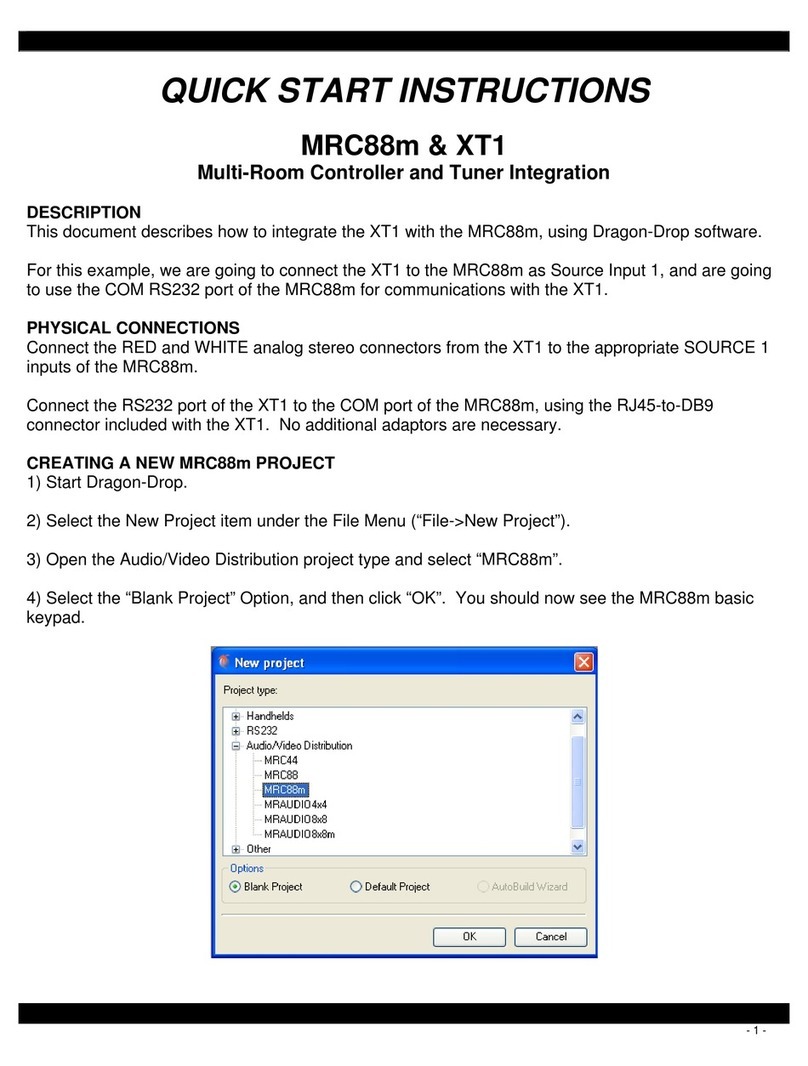

1. Click “LINKS” in DRAG460.

2. Click on Remote Central Website. Your browser will open and take you to Remote Central.com.

3. Click Files in Remote Central.

4. Click Philips Pronto & Marantz RC5000.

5. Scroll and click on desired brand under "Component Configurations" (CCF files).

6. Click on component type (CD players, VCR's, etc.).

7. From the list find a Model Number the same as your model or one similar to it. (Even model numbers

considerably different than yours will usually have commands that work).

8. Click on DOWNLOAD (this may take a few seconds), then select Save it to disk, then OK.

9. In the Windows ‘Save As…’ pop-up, Open the ccf folder within the Drag460 folder (if not already open). Click

Save.

10. In DRAG460, click Import CCF from the File menu.

11. Find the ccf folder in which you saved the file and click on file name.

NOTE: At this point, prior to opening it, you may wish to change the file name (e.g., RCA-DSS, etc.) for

easier recognition later. You may wish to do this in step 13 as well.

12. Click Open. This unzips the file and DRAG460 automatically places it in a folder within the ccf folder.

13. Click on file name, then on Open. At this point, the CCF file is converted to DRAG460 format.