4CTC EcoComfort

Table of contents

Congratulation on buying your new product! ___________ 5

Safety instructions _____________________________ 6

Check list ______________________________________________________________________ 7

The check list must be completed by the installer.__________7

Pipe installation __________________________________________________________7

Electrical installation____________________________________________________7

Customer information (adapted to the relevant installation)7

1. Installation______________________________________________________________ 8

1.1 Scope of delivery _______________________________________________8

1.2 Important to remember!______________________________________8

1.3 Technical data____________________________________________________9

1.4 Dimensional drawing __________________________________________9

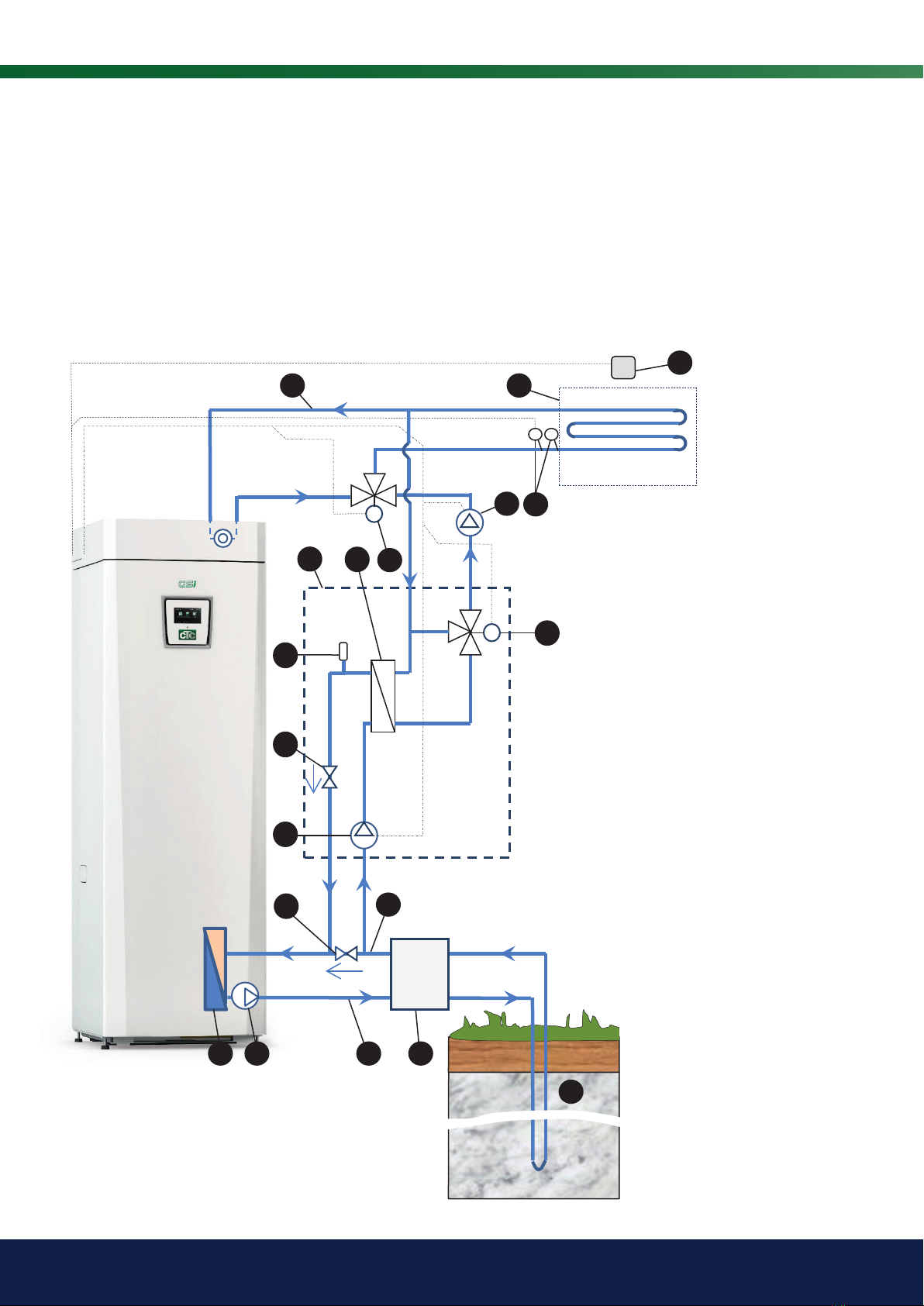

2. Schematic diagrams___________________________________________ 10

2.1 Alt. 1. Connection to the CTC controlling product,

common underfloor heating/cooling ___________________ 10

2.2 Alt. 2. Connection to the CTC controlling product,

underfloor/radiator heating and separate cooling coil

units _______________________________________________________________11

2.3 Component location_________________________________________12

3. Pipe installation___________________________________________________ 13

3.1 General___________________________________________________________13

3.2 Mounting_________________________________________________________13

3.3 Water quality, cold side _____________________________________13

3.4 Water quality, hot side_______________________________________ 13

3.5 Delivery inspection ___________________________________________13

3.6 General comment on pipe installation_________________ 13

3.7 Connection to the heating system______________________13

3.8 Connecting the diverting valve (Y60)___________________14

3.9 Non-return valve, cooling circuit_________________________15

3.10 Non-return valves, main circuit’s brine system _____15

3.11 Bleeding the cooling unit___________________________________ 15

3.12 Connection to the brine system _________________________15

3.13 Insulating the pipes __________________________________________15

3.14 Pressure drop curves for CTC EcoComfort _________16

4. Electrical connection __________________________________________ 17

4.1 Alt. 1. Connection to CTC controlling product, com-

mon underfloor heating/cooling _________________________18

4.2 Alt. 2. Connection to CTC controlling product, un-

derfloor/radiator heating and separate cooling coil

units _______________________________________________________________18

5. First start______________________________________________________________ 19

5.1 After installation _______________________________________________ 19

5.2 Start-up __________________________________________________________19

5.3 Selecting cooling function _________________________________ 19

5.4 Selecting system type/Menu settings _________________ 19

5.5 Bleeding and function test_________________________________ 19

6. Operation and maintenance ______________________________ 20

6.1 After installation _______________________________________________ 20

6.2 Periodic maintenance _______________________________________20

6.3 Breaks in operation __________________________________________ 20

6.4 Function description_________________________________________20

6.5 Function options _____________________________________________21

7. Troubleshooting and remedial action _______________ 23

7.1 Capacity data __________________________________________________24

For your own reference

Fill in the information below. It may come in useful if anything should happen.

Product: Manufacturing number:

Installer: Name:

Date: Tel. no.:

Electrical installer: Name:

Date: Tel. no.:

Enertech AB provides the information with reservation for any printing errors and subject to modification.