2

1. INTRODUCTION

1.1. SAFETY

1.1.1. Before beginning the tank installation, read through the

entire Installation Manual and Operating Guidelines

(subsequently referred to as “Installation Manual” . It is the

responsibility of the owner, installer and operator to follow all

requirements contained in this Installation Manual and comply

with all federal, state and local safety regulations that may apply

to tank installations and operations.

1.1.2. No instructions or procedures presented in this Installation

Manual should be interpreted so as to put at risk any person’s

health or safety, or to harm any property or the environment.

1.1.3. The following definitions will serve as a guide when

reading the Installation Manual:

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not

avoided, may result in minor or moderate injury.

A Caution without the safety alert symbol indicates a

potentially hazardous situation, which, if not avoided, may

result in property damage.

1.1.4. Keep this Installation Manual available at the installation

site to refer to safety procedures as needed.

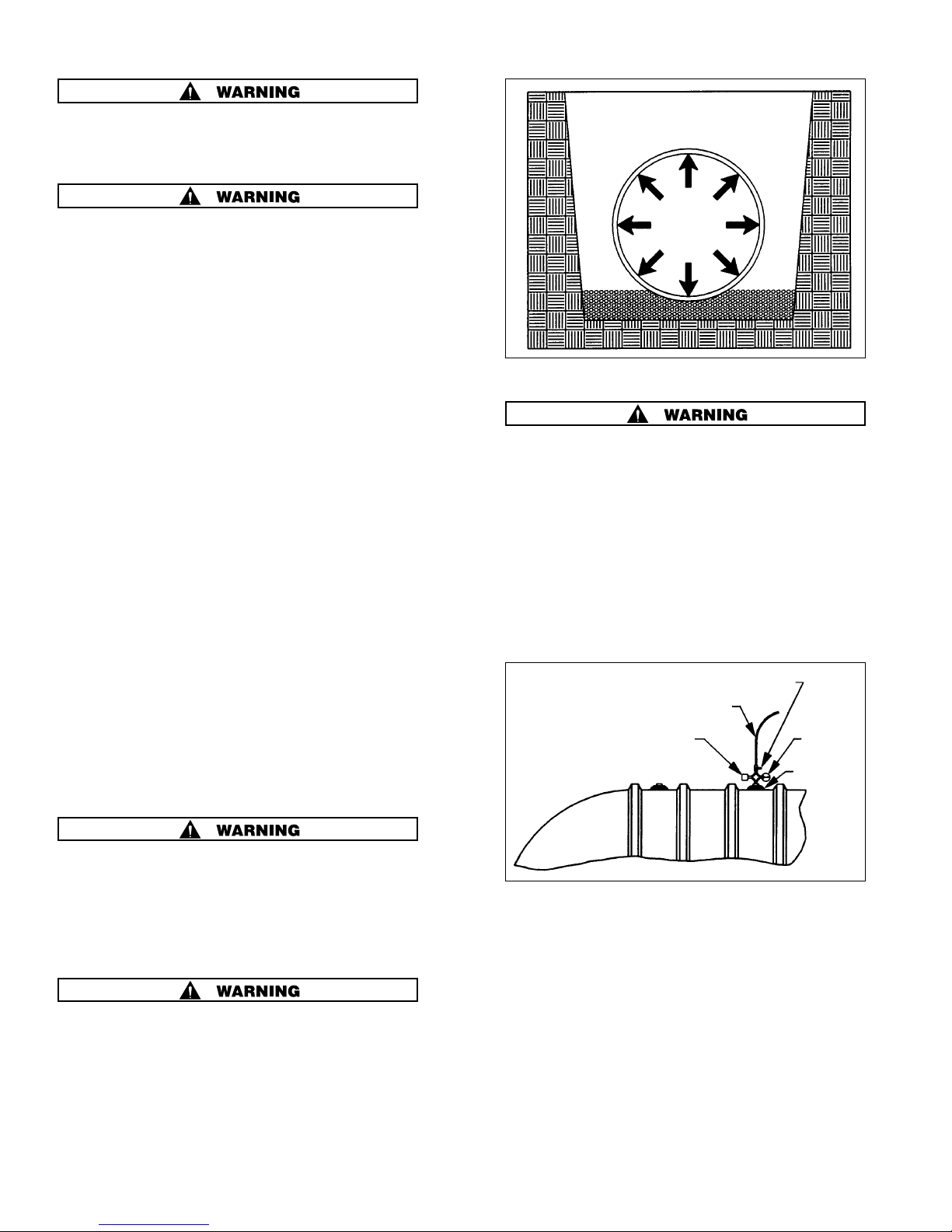

Follow O HA regulations for tank excavations. Collapse of

excavation walls could result in death or serious injury.

1.1.5. Working in and around excavations is dangerous. The

Occupational Safety and Health Administration (OSHA has

specific requirements that must be followed. Prior to beginning

work at the site, the installer must obtain a copy of OSHA’s

Standard, Part 1926, Subpart P(Excavations , 650-652. A copy

of this standard is available free of charge at OSHA’s Website:

www.osha.gov.

Read all instructions and operating guidelines before installation.

To Installer: Before installation, read Installation Manual and Operating Guidelines. After installation,

give Installation Manual and Operating Guidelines to owner.

To Owner: After installation, retain Installation Manual and Operating Guidelines for future reference to

operating guidelines.

1.1.6. Careless activity or reckless operation of equipment can

cause death, serious injury or property damage.

1.2. GENERAL

1.2.1. It is important to follow the procedures and instructions in

this manual in order to safely and properly install a Xerxes

underground storage tank and accessories. Failure to follow

these instructions will void the tank warranty and may cause

tank failure, serious personal injury or property damage.

1.2.2. The Xerxes warranty applies only to a tank installed

according to these instructions. Since Xerxes does not control

the parameters of any installation, Xerxes’ sole responsibility in

any installation is that presented in our warranty.

1.2.3. It is the responsibility of the owner and operator to always

follow the operating guidelines set forth in Xerxes’ applicable

warranty and Section 18 of this Installation Manual. A Xerxes

warranty is found in each product brochure or is available upon

request from the UST coordinator at the Xerxes plant nearest

you. It is the responsibility of the owner to retain this Installation

Manual for future reference to operating guidelines.

1.2.4. Use the Tank Installation Checklist (included in this

manual for all single-wall tanks (SWT , double-wall tanks

(DWT , oil/water separators (OWS and multicompartment tanks

(MCT as the installation proceeds. Retain a copy of the

completed Tank Installation Checklist, and any correspondence,

certification, etc., related to the tank. Each tank requires a

separate Tank Installation Checklist. Consult your Xerxes

representative or distributor if additional Tank Installation

Checklist forms are needed.

1.2.5. The tank owner and/or installing contractor should retain a

copy of the Tank Installation Checklist to facilitate any warranty

claim.

1.2.6. Comply with all applicable regulations and standards,

such as:

• federal, state and local construction, health, safety and

environmental codes;

• National Fire Protection Association standards (for example,

NFPA 30, 30A and 31 ;

• industry standard practices (for example, PEI RP100, API

RP1615 ;

• EPA reference materials (for example, “Doing It Right” .

1.2.7. For additional information, contact your state, county and

city storage-tank authorities, including health, fire or building

departments, and environmental agencies. All work must be

performed according to standard industry practices and OSHA

regulations.